Industrial boiler flue gas dehumidifying desulphurization denitration system and method

A desulfurization and denitrification, industrial boiler technology, applied in separation methods, chemical instruments and methods, agriculture, etc., can solve problems such as insufficient water resistance and sulfur resistance, and achieve the effects of improving effective service life, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

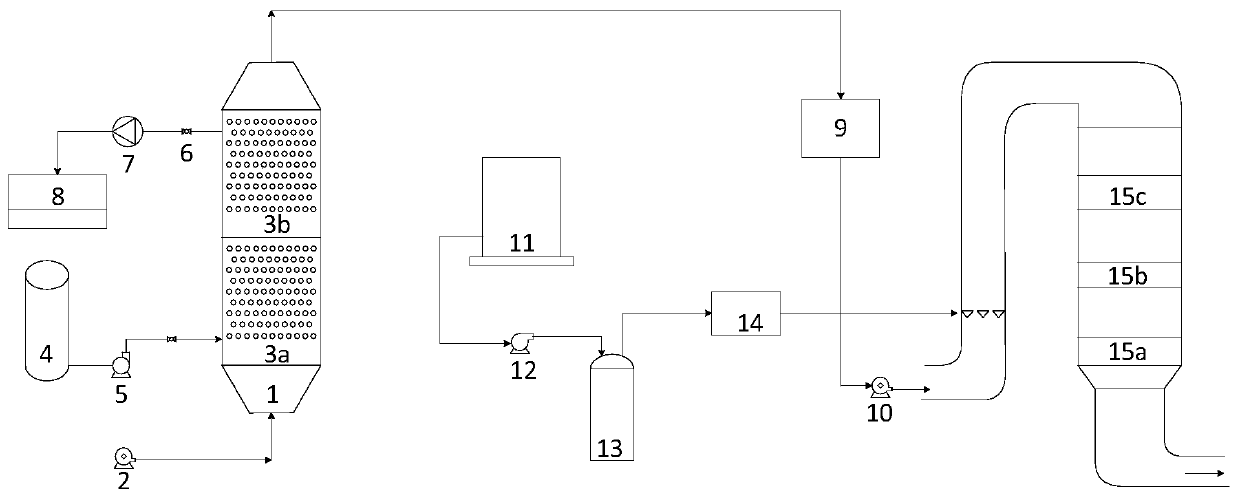

Image

Examples

Embodiment 1

[0044] 1) The flue gas is transported to the dehumidification and desulfurization tower 1 through the booster fan 2, and the flue gas is dehumidified and desulfurized by a hollow fiber membrane absorber formed by connecting two hollow fiber membranes in series. The mass concentration of the absorption liquid is 0.5%, The temperature is 70°C, the gas-liquid ratio is 75:1, and the vacuum degree inside the tube side of the fiber membrane absorber is 0.06MPa.

[0045] 2) The dehumidified and desulfurized flue gas enters the flue gas heater to be heated to 100°C, and then enters the denitrification tower through the induced draft fan.

[0046] 3) The flue gas at a temperature of 100°C enters the low-temperature denitrification tower for low-temperature denitrification treatment. The low-temperature denitrification catalyst is a low-temperature SCR with anatase-type nano-titanium dioxide as the carrier and cerium and vanadium metal oxides as active components. Catalyst, the molar ra...

Embodiment 2

[0049] 1) The flue gas is transported to the dehumidification and desulfurization tower 1 through the booster fan 2, and the flue gas is dehumidified and desulfurized by a hollow fiber membrane absorber formed by connecting two hollow fiber membranes in series. The mass concentration of the absorption liquid is 0.8%, The temperature is 90°C, the gas-liquid ratio is 100:1, and the vacuum inside the tube side of the fiber membrane absorber is 0.1MPa.

[0050] 2) The dehumidified and desulfurized flue gas enters the flue gas heater to be heated to 140°C, and then enters the denitrification tower through the induced draft fan.

[0051] 3) The flue gas at a temperature of 140°C enters the low-temperature denitrification tower for low-temperature denitrification treatment. The low-temperature denitrification catalyst is a low-temperature SCR with anatase-type nano-titanium dioxide as the carrier and cerium and vanadium metal oxides as active components. Catalyst, the molar ratio of ...

Embodiment 3

[0054] 1) The flue gas is transported to the dehumidification and desulfurization tower 1 through the booster fan 2, and the flue gas is dehumidified and desulfurized by a hollow fiber membrane absorber formed by connecting two hollow fiber membranes in series. The mass concentration of the absorption liquid is 0.6%, The temperature is 80°C, the gas-liquid ratio is 90:1, and the vacuum degree inside the tube side of the fiber membrane absorber is 0.08MPa.

[0055] 2) The dehumidified and desulfurized flue gas enters the flue gas heater to be heated to 180°C, and then enters the denitrification tower through the induced draft fan.

[0056] 3) The flue gas at a temperature of 140°C enters the low-temperature denitrification tower for low-temperature denitrification treatment. The low-temperature denitrification catalyst is a low-temperature SCR with anatase-type nano-titanium dioxide as the carrier and cerium and vanadium metal oxides as active components. Catalyst, the molar ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com