Vacuum system applied to production of acrylic acid and acrylate

An acrylic and vacuum system technology, which is applied in the field of vacuum systems, can solve the problems of high production and operation costs, easy fluctuations in vacuum production, and instability, and achieve the effects of reducing operating costs, uniform suction, and stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

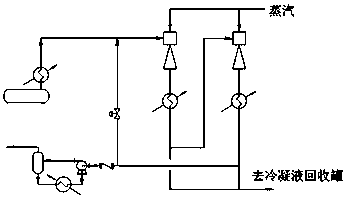

[0028] The invention discloses a vacuum system applied to the production of acrylic acid and acrylic esters. The vacuum system includes a tower top buffer tank, a tail gas condenser, a multi-stage Roots vacuum unit, a post-stage condenser, a gas-liquid separation tank and a water ring vacuum pump. ;The buffer tank on the top of the tower is connected with the top air inlet of the tail gas condenser, and the exhaust gas enters the tail gas condenser, and the side outlet of the lower part of the tail gas condenser is connected with the inlet end of the multi-stage Roots vacuum unit, and the multi-stage Roots vacuum unit The gas outlet is connected to the post-stage condenser, the post-stage condenser is connected to the gas-liquid separation tank inlet, and the gas-liquid separator gas outlet is connected to the water ring vacuum pump.

[0029] In this embodiment, the multi-stage Roots vacuum unit is composed of multiple Roots vacuum pumps connected in series, and an interstage c...

Embodiment 2

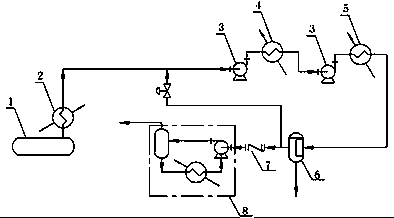

[0031] The invention discloses a vacuum system applied to the production of acrylic acid and acrylic esters. The vacuum system includes a tower top buffer tank, a tail gas condenser, a multi-stage Roots vacuum unit, a post-stage condenser, a gas-liquid separation tank and a water ring vacuum pump. ;The buffer tank on the top of the tower is connected with the top air inlet of the tail gas condenser, and the exhaust gas enters the tail gas condenser, and the side outlet of the lower part of the tail gas condenser is connected with the inlet end of the multi-stage Roots vacuum unit, and the multi-stage Roots vacuum unit The gas outlet is connected to the post-stage condenser, the post-stage condenser is connected to the gas-liquid separation tank inlet, and the gas-liquid separator gas outlet is connected to the water ring vacuum pump.

[0032] In this embodiment, the multi-stage Roots vacuum unit is composed of multiple Roots vacuum pumps connected in series, and an interstage c...

Embodiment 3

[0034] The invention discloses a vacuum system applied to the production of acrylic acid and acrylic esters. The vacuum system includes a tower top buffer tank, a tail gas condenser, a multi-stage Roots vacuum unit, a post-stage condenser, a gas-liquid separation tank and a water ring vacuum pump. ;The buffer tank on the top of the tower is connected with the top air inlet of the tail gas condenser, and the exhaust gas enters the tail gas condenser, and the side outlet of the lower part of the tail gas condenser is connected with the inlet end of the multi-stage Roots vacuum unit, and the multi-stage Roots vacuum unit The gas outlet is connected to the post-stage condenser, the post-stage condenser is connected to the gas-liquid separation tank inlet, and the gas-liquid separator gas outlet is connected to the water ring vacuum pump.

[0035] In this embodiment, the multi-stage Roots vacuum unit is composed of multiple Roots vacuum pumps connected in series, and an interstage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com