Wet-process six- station molding device for high-strength concrete product

A high-strength concrete, six-station technology, applied in auxiliary forming equipment, forming indenters, ceramic forming machines, etc., can solve the problems of inability to produce high-strength concrete product equipment, low absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

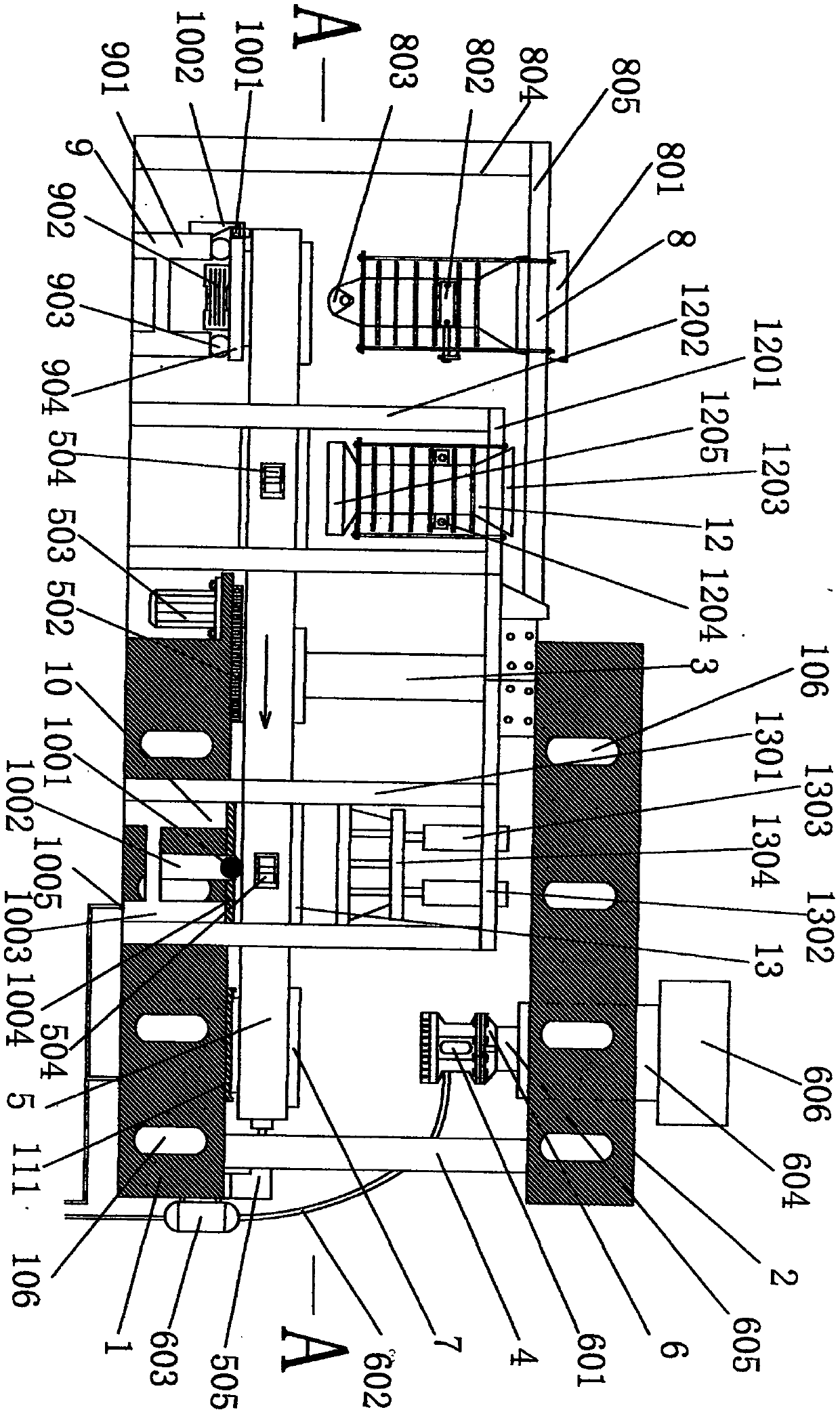

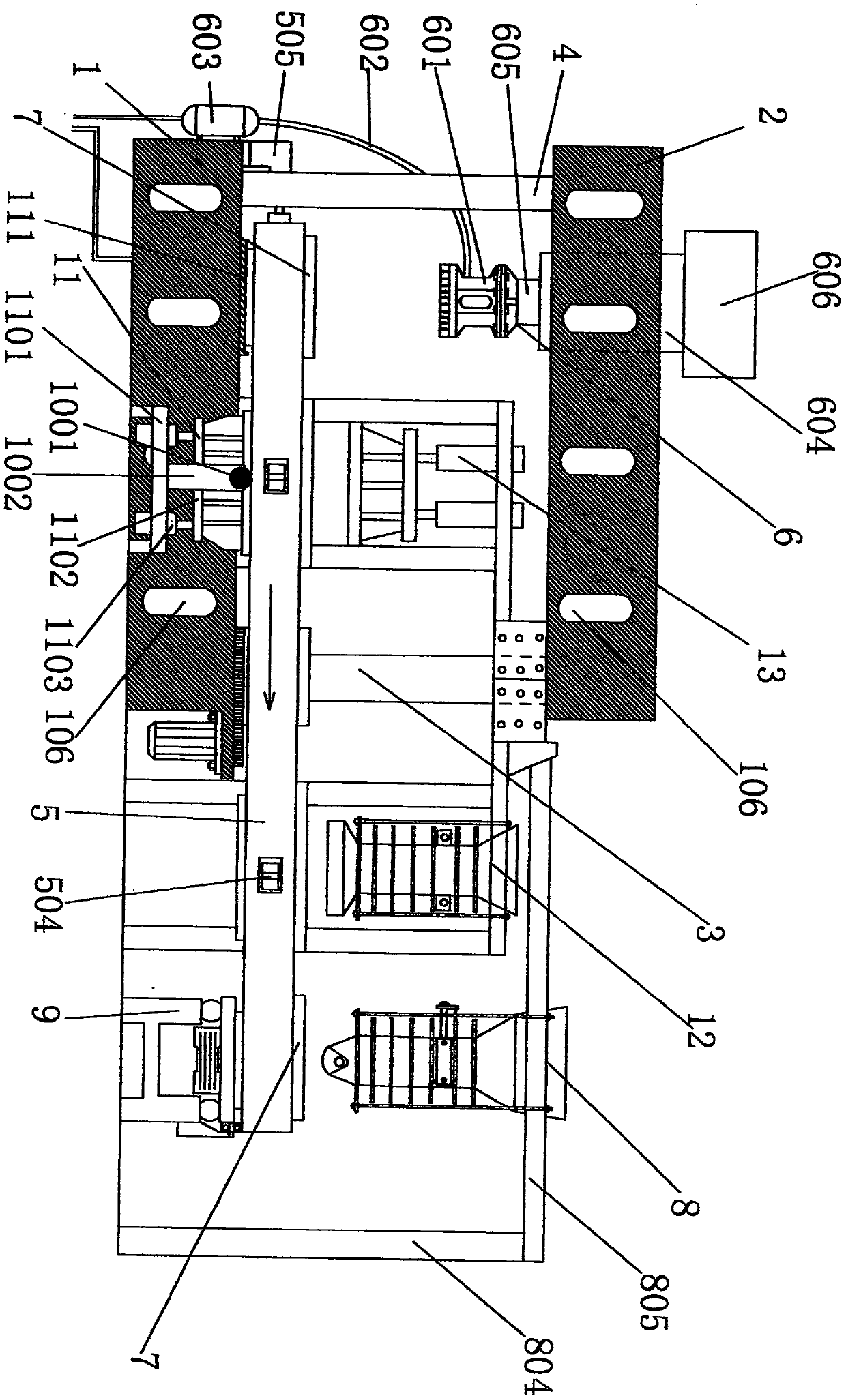

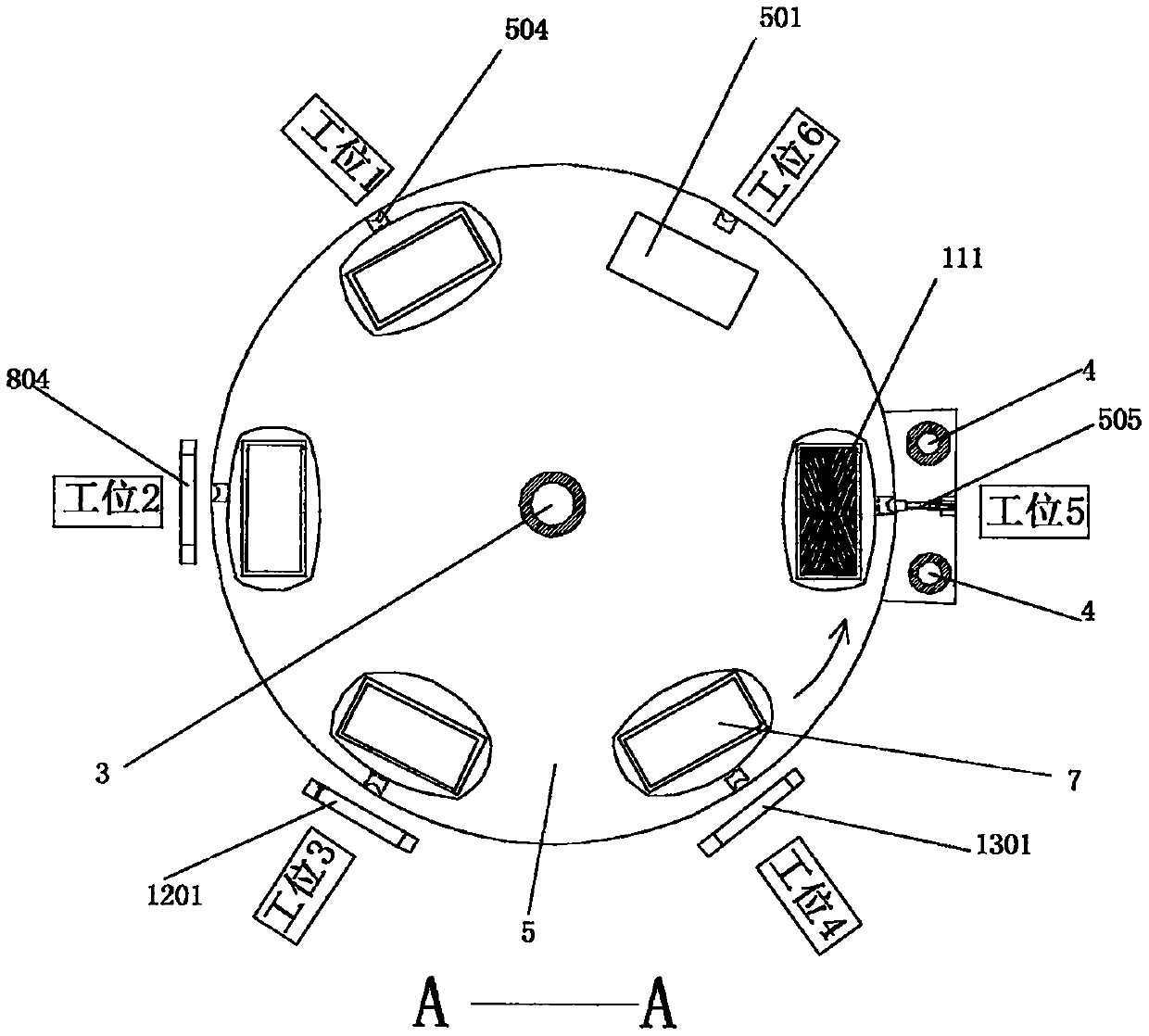

[0116] The present invention is achieved like this, below in conjunction with appendix Figure 1 to Figure 17 For further explanation: a wet-process six-station forming high-strength concrete product equipment, consisting of a box-type lower beam 1, a box-type upper beam 2, an independent fixed column 3, double columns 4, a rotating disc 5, and an upper die head part 6 , lower mold box 7, base material metering device 8, vibration platform 9, support platform 10, demoulding device 11, fabric metering device 12, pre-pressing device 13;

[0117] The box-type lower beam 1 is located on the foundation level, the box-type upper beam 2 is located directly above the box-type lower beam 1; the independent fixed column 3 and the double column 4 are respectively located on the box-type lower beam. The two ends of the beam 1 and the box-type upper beam 2 are respectively inserted into the independent column connection holes 101 and the double-column connection holes 102 at the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com