Monocular vision deviation detection method and monocular vision deviation detection device for AGV

A technology of deviation detection and monocular vision, applied in image data processing, instruments, calculations, etc., can solve problems such as high cost, unfavorable production costs, and loss of useful information, and achieve strong resistance, strong adaptability, and strong filtering effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

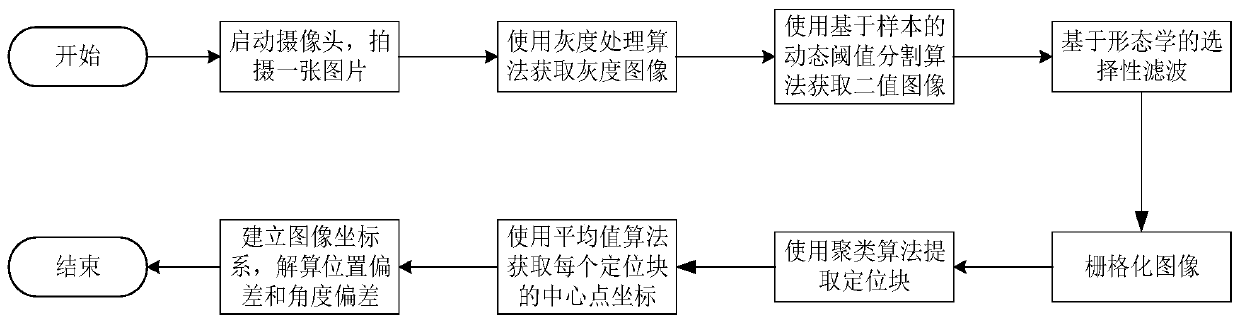

[0059] The present invention provides a monocular visual deviation detection method for AGV, such as figure 1 As shown, it includes the following steps:

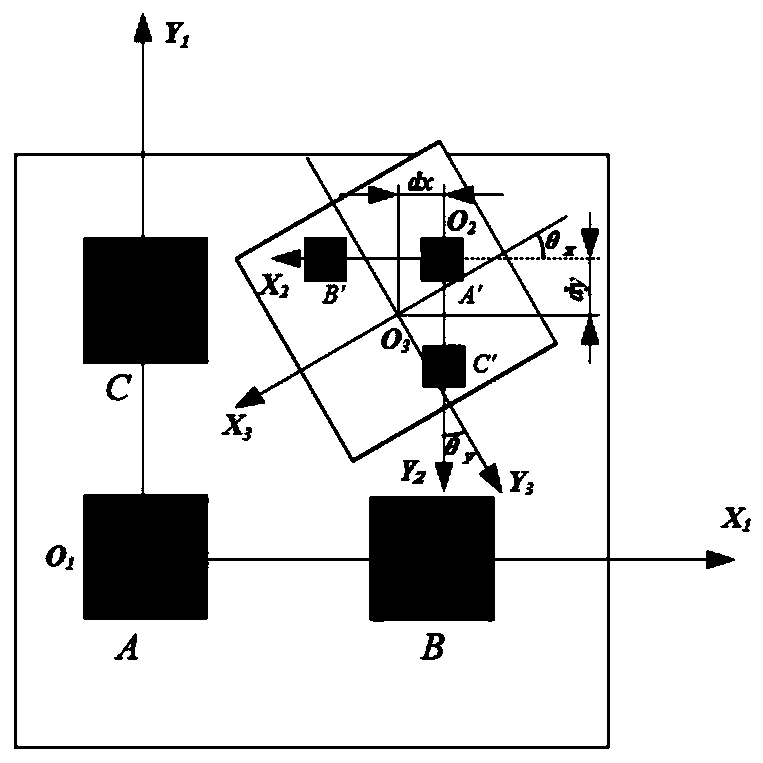

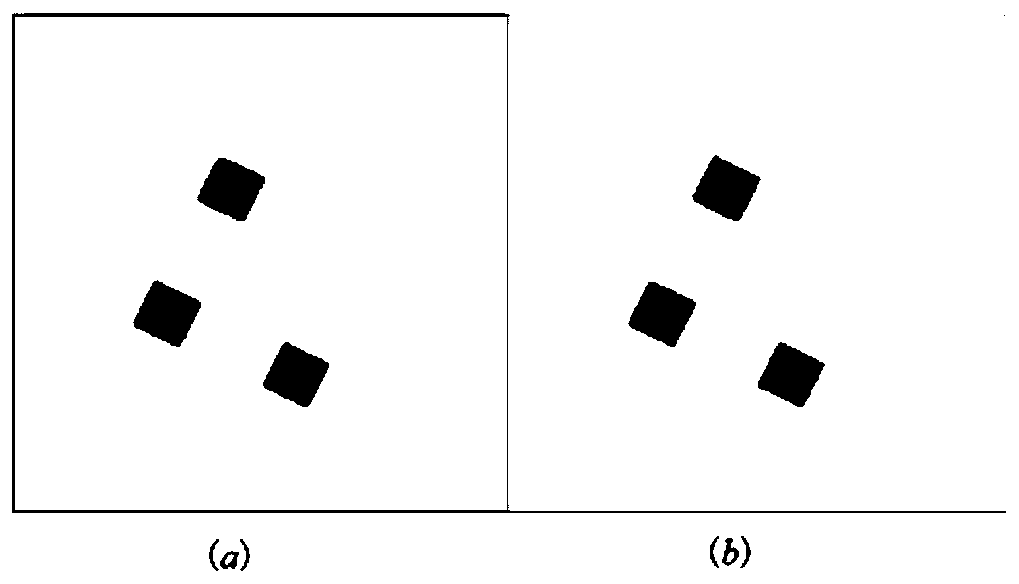

[0060] S0. Start the camera and take a frame of pictures. The image data is obtained by photographing the beacon, which contains three positioning blocks, each positioning block is a figure with at least one set of vertical symmetry axes, such as a circle, a square, a rectangle or a rhombus, and three The center point of the positioning block can constitute a Cartesian coordinate system.

[0061] S1. Perform grayscale processing on the image data collected by the image sensor. The weighted average grayscale processing algorithm based on R, G, and B components is used to grayscale the image to enlarge the difference between the foreground color and the background color. Specifically include:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com