High-efficiency textile oven

A high-efficiency, textile technology, used in textiles and papermaking, drying, dryers, etc., can solve the problems of inability to remove textile dust, low production efficiency, and high labor intensity, improve drying quality and appearance, and benefit Follow-up processing to ensure beautiful results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

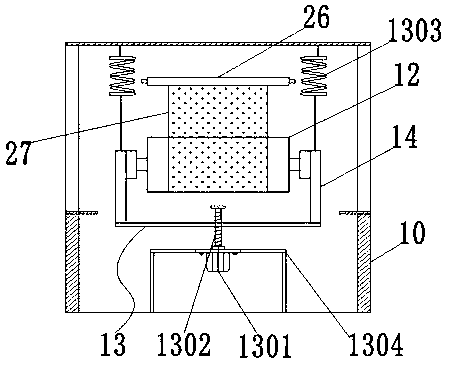

[0032] Such as Figure 1-4As shown, a high-efficiency textile oven includes a box body 1, and the box body 1 is provided with a drying room 2, a conditioning room 3, a wrinkle removal room 4 and a dust removal room 5, and the number of the conditioning room 3 can be one or two. The conditioning chamber 3 can be set between the drying chamber 2 and the wrinkle removing chamber 4, or between the wrinkle removing chamber 4 and the dust removing chamber 5, or two at the same time, respectively located between the drying chamber 2 and the wrinkle removing chamber 4 between the wrinkle removal chamber 4 and the dust removal chamber 5; the upper drying drum 6 and the lower drying drum 7 are arranged in the drying chamber 2, the upper drying drum 6 and the lower drying drum 7 have the same size, and the upper drying drum 6 passes through the bearing housing 8 Connected with the upper support frame 9, the lower drying drum 7 is connected with the lower support frame 10 through the bear...

Embodiment 2

[0034] After the textile 27 enters the drying chamber 2 through the reversing roller 26 on the outer wall of the box body 1, the upper surface is fully dried by the lower drying cylinder 7 in the drying chamber 2 first, and then the lower surface is fully dried by the upper drying cylinder 6. The selection of parameters such as the size, rotating speed, and effective heating area of the drum 6 and the lower drying drum 7 ensures that the textile 27 meets the drying standard within the contact time of the upper drying drum 6 and the lower drying drum 7; Anti-deflection rollers 11 are respectively provided on both sides of the side and the lower drying cylinder 7 to prevent the textiles 27 from running off during movement; under the action of the reversing rollers 26, the textiles 27 adjust the angle to reduce wear and enter the adjustment chamber 3; Under the action of the adjusting roller 12 and the tensioning device 13 in the adjustment chamber 3, the textile 27 is straighte...

Embodiment 3

[0036] For some textiles 27 with poor elasticity and hard materials, larger wrinkles may be generated during processing or transportation, and it is necessary to prolong the ironing time to achieve a satisfactory wrinkle removal effect; Micro switch, through the selection of the micro switch, determine the stroke size of the micro switch action, when the height of the fold is less than the stroke of the micro switch action, the micro switch does not act, according to the normal method in embodiment 2 Carry out wrinkle removal to textile 27; When the height of fold is greater than the stroke of microswitch action, microswitch action, carry out wrinkle removal to textile 27 according to this embodiment; Upper microswitch 28 and lower microswitch 29 preferred models are : SV-165-1C25 type, the action stroke can be controlled at 6mm, focusing on removing larger wrinkles above 6mm; the roller of the upper micro switch 28 is attached to the lower surface of the textile 27, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com