A kind of rebar containing Ti and preparation method thereof

A technology of rebar and molten steel, which is applied in the field of alloy steel, can solve the problems of rebar with many chemical components, complex adjustment of chemical composition, and various performances to be improved, so as to achieve the effect of eliminating internal defects and uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

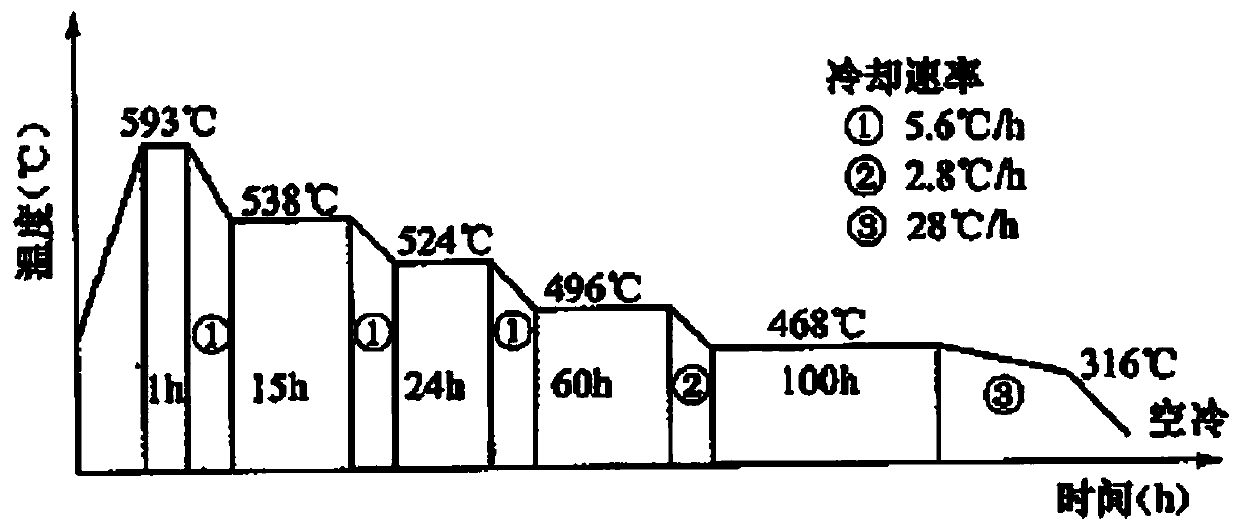

Image

Examples

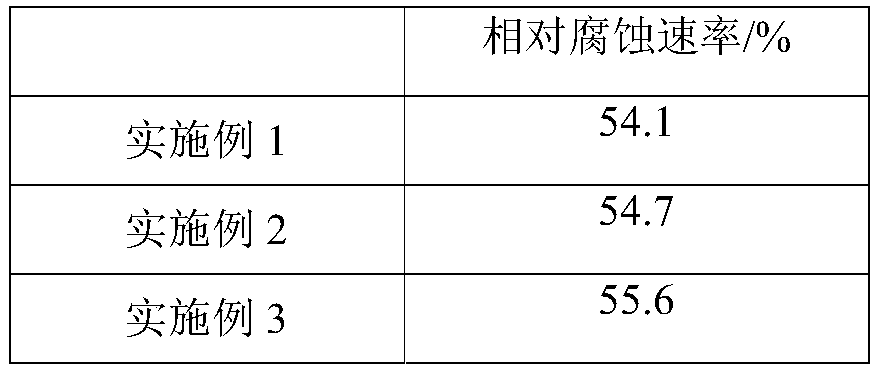

Embodiment 1

[0060] A Ti-containing rebar, including the following chemical composition in weight percentage: C: 0.20%, Si: 0.40%, Mn: 1.20%, Ti: 0.015%, Nb: 0.015%, P: 0.045%, S: 0.045%.

[0061] The preparation method of above-mentioned screw steel, comprises the steps:

[0062] (1) Converter smelting: add steel scrap, supply oxygen (oxygen pressure 0.8MPa, gun position 1.4m), add 1.2wt% lime (accounting for the weight fraction of scrap steel) to make slag, blow argon gas at the bottom of the whole process, the flow rate is 60NL / min, the end point For temperature measurement and sampling, first add a deoxidizer to deoxidize. The main components of the deoxidizer are Si: 0.4%, Ca: 4%, Al: 15%, and silicon-manganese, ferrosilicon, ferro-niobium and ferro-titanium are added for alloying, and the steel is tapped for 1 / 5 starts to add alloy, and all the addition is completed before 3 / 4 of the steel is tapped. The order of alloy addition is silicomanganese-ferrosilicon-ferro-niobium-ferro-tit...

Embodiment 2

[0068] A Ti-containing rebar, including the following chemical composition in weight percentage: C: 0.25%, Si: 0.55%, Mn: 1.40%, Ti: 0.025%, Nb: 0.020%, P: 0.025%, S: 0.025%.

[0069] The preparation method of above-mentioned screw steel, comprises the steps:

[0070] (1) Converter smelting: add molten iron, supply oxygen (oxygen pressure 0.9MPa, gun position 1.8m), add 2.8wt% lightly burned dolomite (accounting for the mass fraction of molten iron) to make slag, and blow argon gas at the bottom during the whole process, with a flow rate of 100NL / Min, temperature measurement and sampling at the end point, first add a deoxidizer to deoxidize, the main components of the deoxidizer are Si: 0.6%, Ca: 6%, Al: 18%, then add silicomanganese, ferrosilicon, ferro-niobium and ferro-titanium for alloying, Alloys start to be added at 1 / 5 of the steel, and all are added before 3 / 4 of the steel is tapped. The order of alloy addition is silicomanganese-ferrosilicon-ferro-niobium-ferro-titan...

Embodiment 3

[0076] A Ti-containing rebar, including the following chemical composition in weight percentage: C: 0.22%, Si: 0.45%, Mn: 1.30%, Ti: 0.020%, Nb: 0.018%, P: 0.035%, S: 0.035%.

[0077] The preparation method of above-mentioned screw steel, comprises the steps:

[0078] (1) Converter smelting: add scrap steel and molten iron, supply oxygen (oxygen pressure 0.85MPa, gun position 1.6m), add 2.0wt% magnesium balls (accounting for the percentage of the total mass of scrap steel and molten iron) to make slag, and blow argon gas at the bottom of the whole process, Flow rate is 80NL / min, temperature measurement and sampling at the end point, first add deoxidizer for deoxidation, the main components of deoxidizer are Si: 0.5%, Ca: 5%, Al: 16%, then add silicomanganese, ferrosilicon, ferro-niobium and ferro-titanium Carry out alloying, start to add alloys at 1 / 5 of the tapping, and complete the addition before 3 / 4 of the tapping, the order of alloy addition is silicomanganese-ferrosilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com