Diatomite functional material and preparation method thereof

A functional material, diatomite technology, applied in the field of diatomite functional materials and its preparation, can solve the problems of low diatomite content and poor product performance, and achieve the effects of reducing pollution, improving product quality, and reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

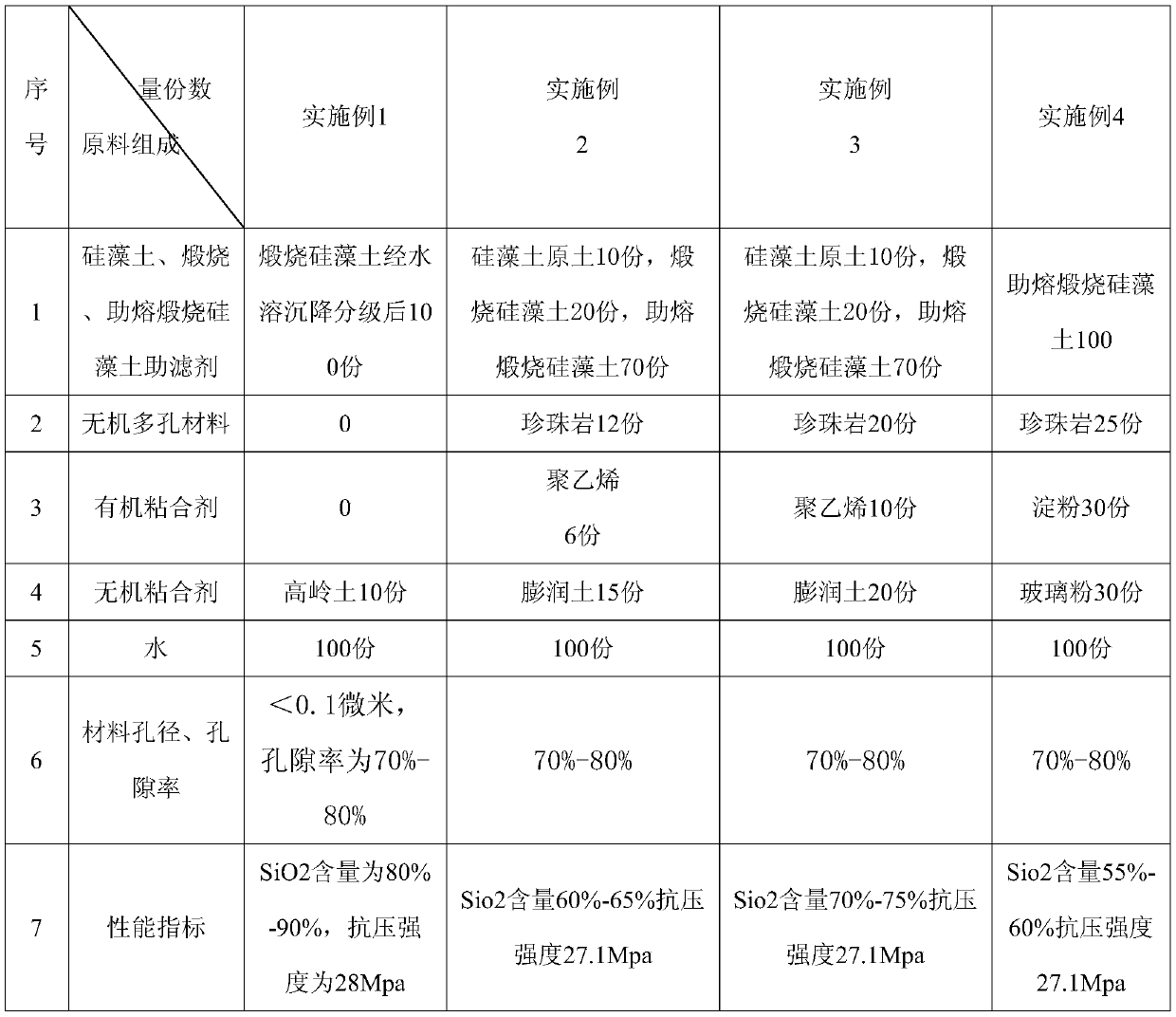

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of diatomite functional material, comprising:

[0040] Step 1: Mix the various raw materials according to the proportion, and then put them into a mold for pressing and molding to obtain a molded body; the molding process is to put the mixture into the mold in the extrusion equipment or pressure equipment for pressing to obtain a plate or column molding body;

[0041] Step 2: put the molded body into a drying room or kiln for drying, the drying temperature is 20-200°C, preferably 90-150°C, and the drying time is 1.5-60h; the drying time depends on the size of the molded product However, when the molded product is small, the drying time is preferably 1.5-4h, more preferably 1.5-2.5h, and when the molded product is large, the drying time is preferably 30-60h, more preferably 25-50h;

[0042] Step 3: After drying, the molded body is shaped and placed in a heating hydraulic press for direct hot-press molding or calci...

Embodiment 1

[0045] Step 1: Mix the raw materials according to the proportions in Table 1, and then put them into a mold for compression molding to obtain a molded body;

[0046] Step 2: put the molded body into a drying room for drying, the drying temperature is 120°C, and the drying time is 2 hours;

[0047] Step 3: After drying, the shaped body is shaped and put into a downdraft kiln for calcination. The calcination temperature is 950°C, and the calcination time is 30 minutes. The calcined shaped body is shaped, engraved or printed to obtain diatomite functional material .

Embodiment 2

[0049] Step 1: Mix the raw materials according to the proportions in Table 1, and then put them into a mold for compression molding to obtain a molded body;

[0050] Step 2: put the molded body into a drying room for drying, the drying temperature is 150°C, and the drying time is 12 hours;

[0051] Step 3: After drying, the molded body is shaped and placed in a heating hydraulic press for direct hot-pressing at 250°C, and the hot-pressed molded body is then shaped, engraved or printed to obtain a diatomite functional material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com