Preparation method of efficient condensation hydrophilic and hydrophobic thin-film coating with multi-scale structure

A hydrophilic-hydrophobic, multi-scale technology, applied in the direction of coating, etc., can solve the problem that the condensation performance of the super-hydrophobic wall surface is difficult to further improve, and achieve the effects of improving condensation efficiency, low reaction temperature, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

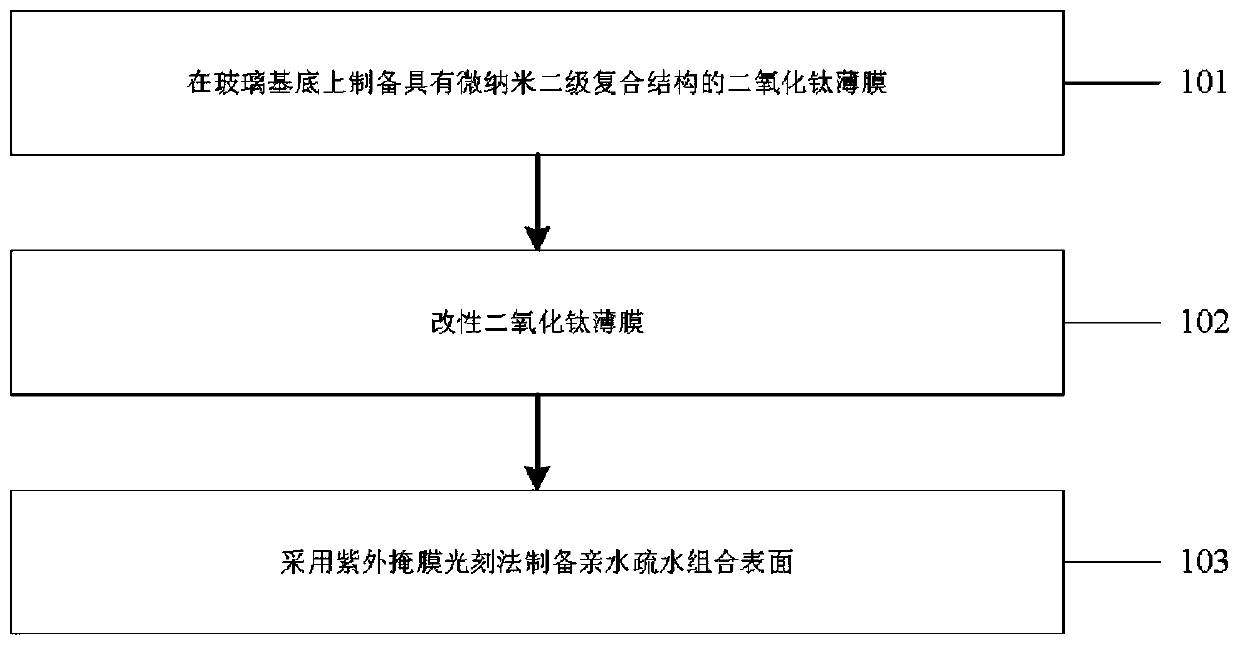

[0043] The invention provides a preparation method of a high-efficiency condensation hydrophilic and hydrophobic film coating with multi-scale structure, such as figure 1 shown, including:

[0044] Step 101, preparing a titanium dioxide film with a micron and nanometer secondary composite structure on a glass substrate;

[0045] Step 102, modifying the titanium dioxide film;

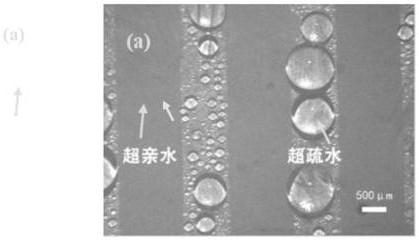

[0046] In step 103, a combined hydrophilic and hydrophobic surface is prepared by using an ultraviolet mask photolithography method.

Embodiment

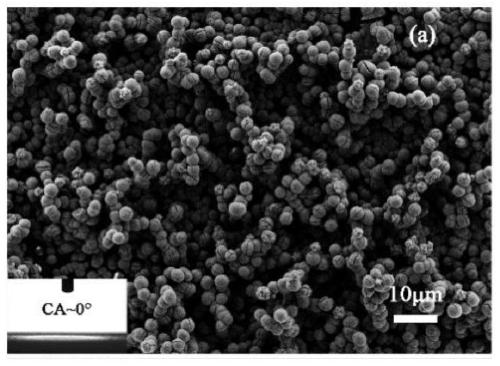

[0049] Step 1: Preparation of TiO2 Thin Films with Micro- and Nano-Secondary Composite Structures

[0050] First, the surface of the glass substrate is treated by a plasma cleaner, and the cleaned glass sheet is placed in a solution of concentrated sulfuric acid: hydrogen peroxide solution = 7:3 (volume ratio), kept in a vacuum drying box at 80 °C for 2 hours, and high-purity water is used. Rinse, place it in an ultrasonic cleaner for 15 minutes, rinse with high-purity water, and finally dry it with high-purity nitrogen for use.

[0051] Put 1 mol / L titanium trichloride solution and add an appropriate amount of sodium chloride and pre-treated glass sheets together into a reaction kettle containing a polytetrafluoroethylene lining (a custom-made bracket is set in the lining, and glass sheets are added. stability in the reactor), uniformly heated from 90°C to 160°C, heating rate of about 1.2°C / min, kept at 160°C for 2 hours, cooled to room temperature, taken out, rinsed slowly w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com