Tempered glass thermal tempering treatment method

A technology of tempered glass and processing method, which is applied in the direction of tempering glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems such as the inability to quickly adjust the spray area, the inability to filter and remove impurities such as dust and particles, and the uneven surface of the glass plate, etc. Achieve rapid adjustment of spray area, good spray adjustment effect, and the effect of being conducive to tempering treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

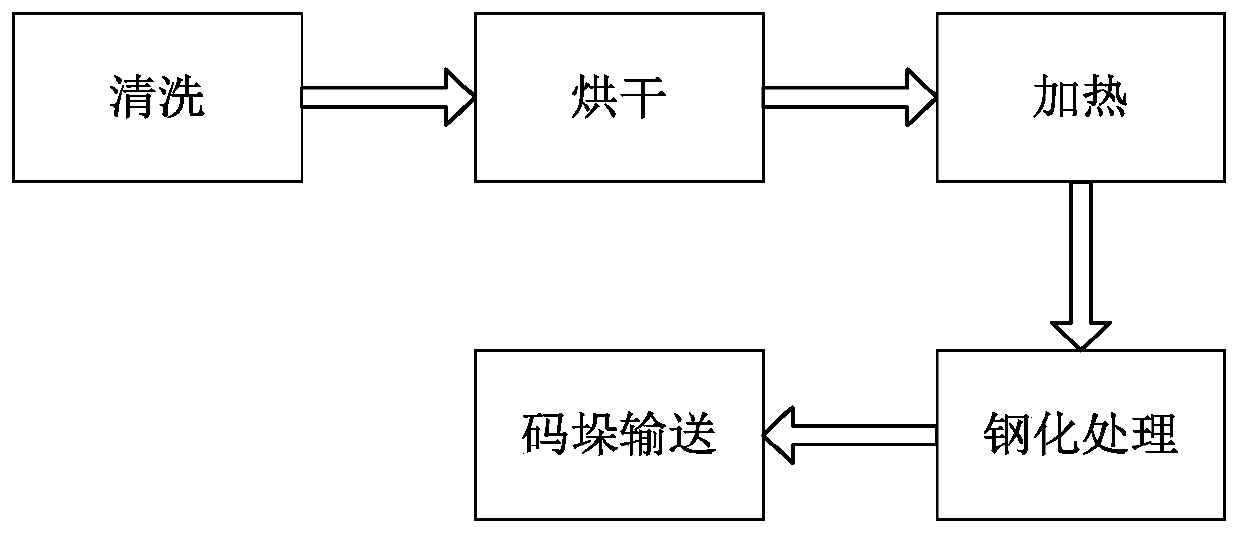

[0036] Such as Figure 1 to Figure 5 Shown, a kind of tempered glass physical toughening treatment method comprises the following steps:

[0037] S1. Cleaning: manually clean the dust and other impurities adhering to the surface of the glass plate to be treated;

[0038] S2. Drying: put the glass plate cleaned in step S1 into the dryer for drying;

[0039] S3. Heating: send the glass plate dried in step S2 into a heating furnace for heating, the heating temperature is 600° C., and the heating time is 4-10 minutes;

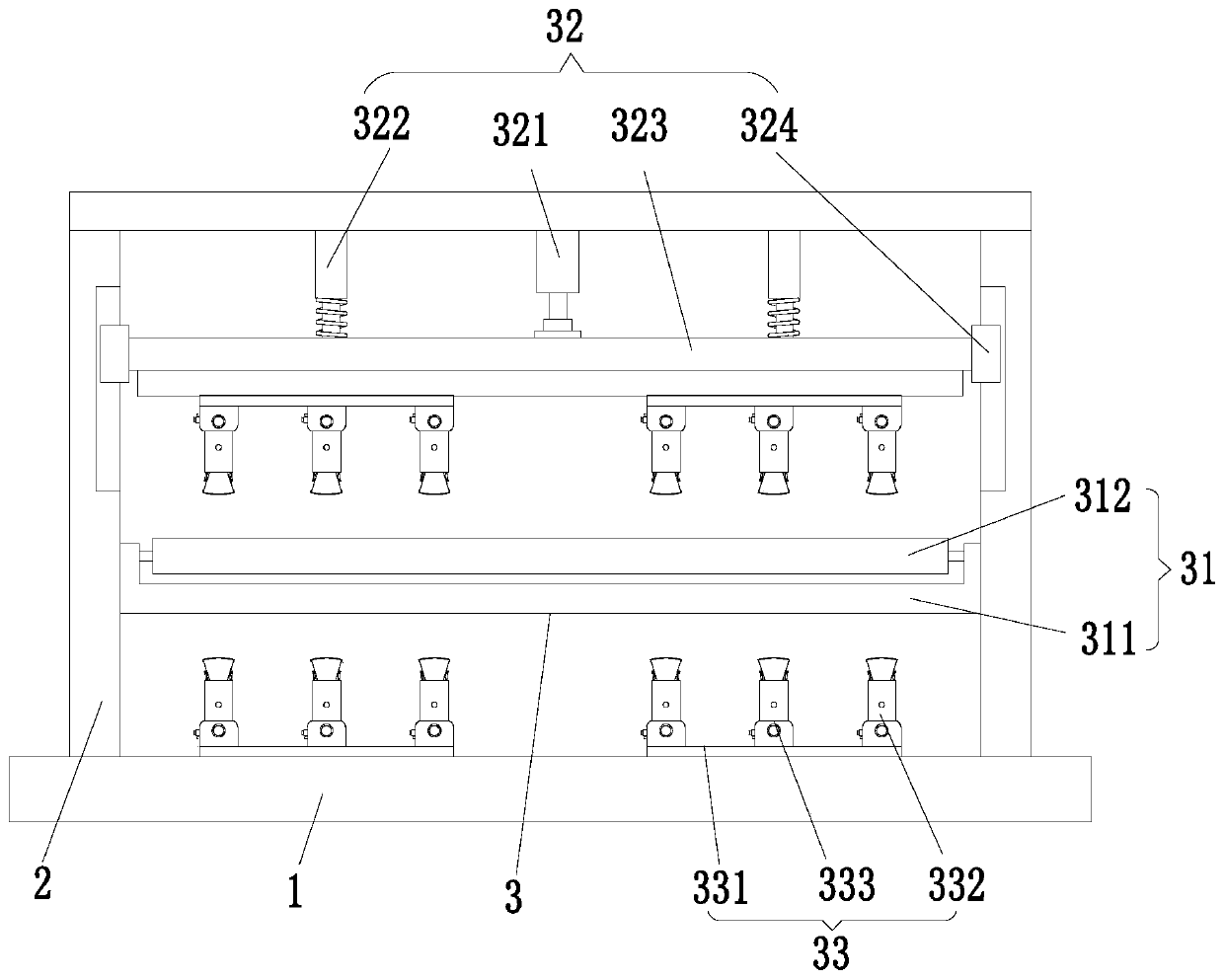

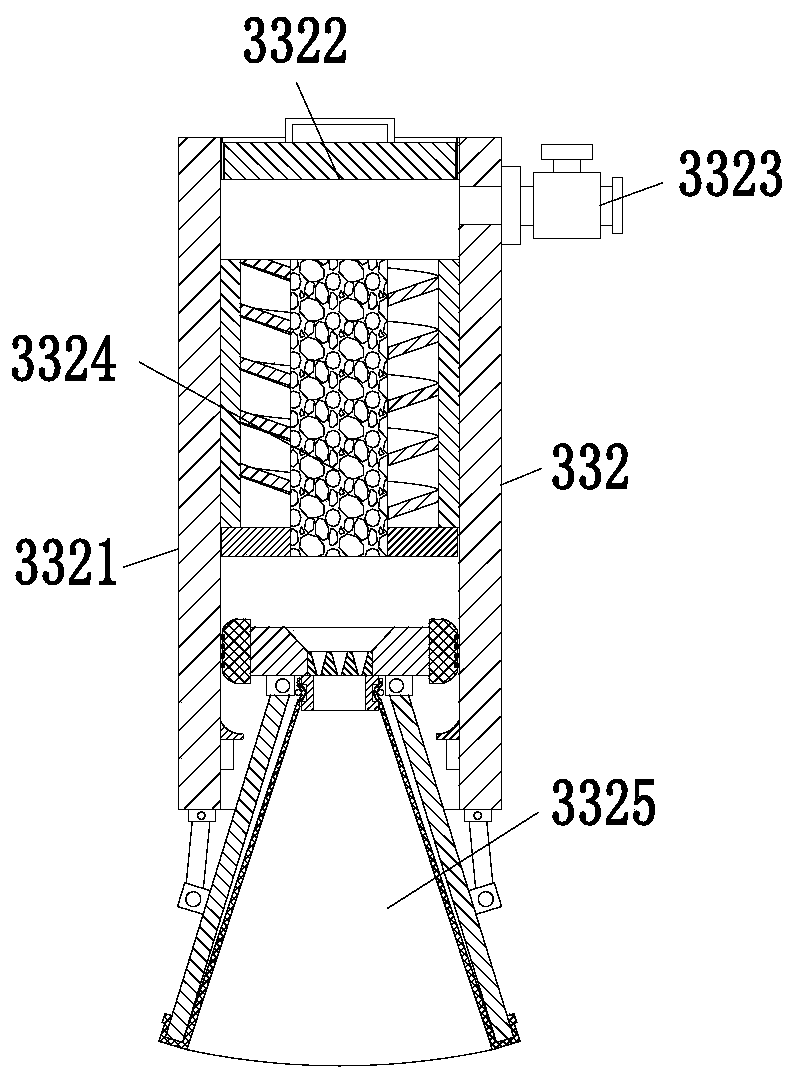

[0040] S4. Tempering treatment: send the heated glass plate into the cooling frame 2, and the tempering treatment device 3 blows high-pressure cold air to both sides of the glass plate to cool it down to room temperature rapidly and ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com