Preparation method for iron-doped pleated graphene aerogel by high-temperature expansion

A technology of graphene airgel and high-temperature expansion, applied in the direction of graphene, nano-carbon, etc., can solve the problems of high contact resistance and low conductivity, reduce oxidation, increase specific surface area, reduce conductivity and mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

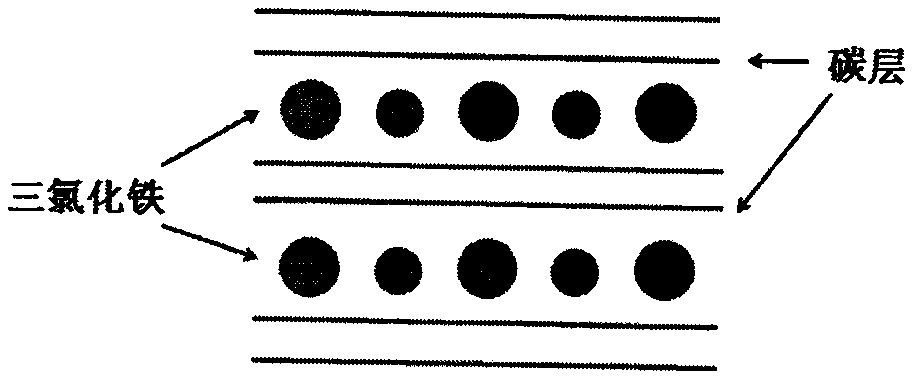

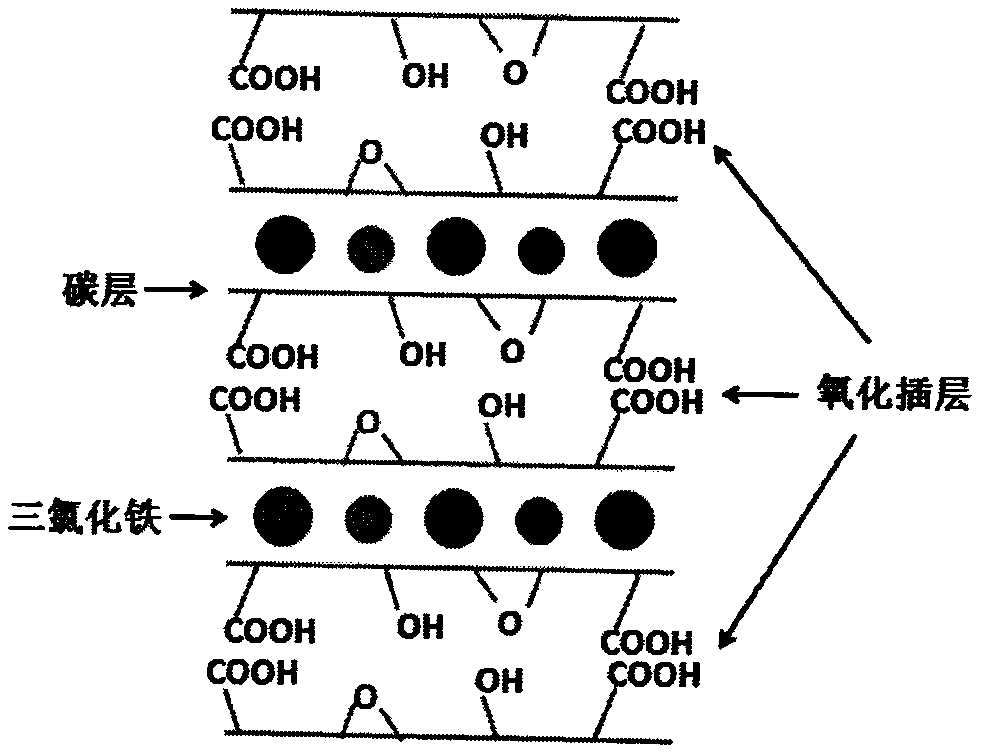

[0028] (1) Mix 300mg of anhydrous ferric chloride and 60mg of expanded graphite evenly, vacuumize, seal in a 50mL glass bottle, and heat at 400°C for 4h to prepare a pure second-order graphite intercalation compound. Dissolve the graphite intercalation compound in Dilute hydrochloric acid solution, filter and dry.

[0029] (2) The graphite intercalation compound was added into a mixed solution of 20 mL of concentrated sulfuric acid and 10 mL of concentrated nitric acid, stirred in ice water (0° C.) for 0.5 hour, 360 mg of sodium chlorate was put into the solution, and stirred at room temperature for 12 hours, The product is centrifuged and cleaned to obtain oxygen-containing group layers and ferric chloride alternately intercalated graphite.

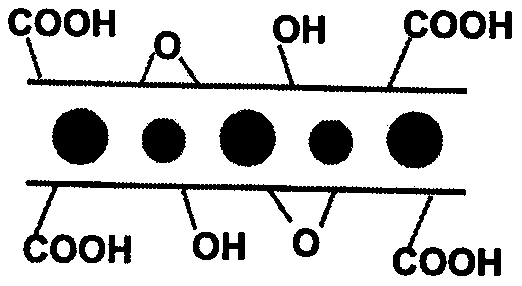

[0030] (3) putting oxygen-containing group layers and ferric chloride intercalated graphite into an aqueous solution for ultrasonic treatment for 1 h to obtain ferric chloride intercalated graphene oxide dispersible in water.

[0031] (...

Embodiment 2

[0034] (1) Mix 300mg of anhydrous ferric chloride and 60mg of expanded graphite evenly, vacuumize, seal in a 50mL glass bottle, and heat at 400°C for 4h to prepare a pure second-order graphite intercalation compound. Dissolve the graphite intercalation compound in Dilute hydrochloric acid solution, filter and dry.

[0035] (2) Add the graphite intercalation compound into 20 mL of concentrated sulfuric acid solution, stir in ice water (0° C.) for 0.5 hours, put 360 mg of potassium permanganate into the solution, stir at room temperature for 12 hours, and centrifuge the product to obtain Oxygen-containing group layers and ferric chloride intercalate graphite alternately.

[0036] (3) putting oxygen-containing group layers and ferric chloride intercalated graphite into an aqueous solution for ultrasonic treatment for 1 h to obtain ferric chloride intercalated graphene oxide dispersible in water.

[0037] (4) Freeze-dry the ferric chloride-intercalated graphene oxide dispersion, ...

Embodiment 3

[0040] (1) Mix 300mg of anhydrous ferric chloride and 60mg of expanded graphite evenly, vacuumize, seal in a 50mL glass bottle, and heat at 400°C for 4h to prepare a pure second-order graphite intercalation compound. Dissolve the graphite intercalation compound in Dilute hydrochloric acid solution, filter and dry.

[0041] (2) The graphite intercalation compound was added into a mixed solution of 20 mL of concentrated sulfuric acid and 10 mL of concentrated nitric acid, stirred in ice water (0° C.) for 0.5 hour, 360 mg of sodium chlorate was put into the solution, and stirred at room temperature for 12 hours, The product is centrifuged and cleaned to obtain oxygen-containing group layers and ferric chloride alternately intercalated graphite.

[0042] (3) putting oxygen-containing group layers and ferric chloride intercalated graphite into an aqueous solution for ultrasonic treatment for 1 h to obtain ferric chloride intercalated graphene oxide dispersible in water.

[0043] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com