Transmission mode electrochemical in-situ optical testing device

An optical testing and electrochemical technology, which is used in measurement devices, color/spectral property measurement, material analysis by optical means, etc., to achieve the effect of being easy to use and easy to assemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

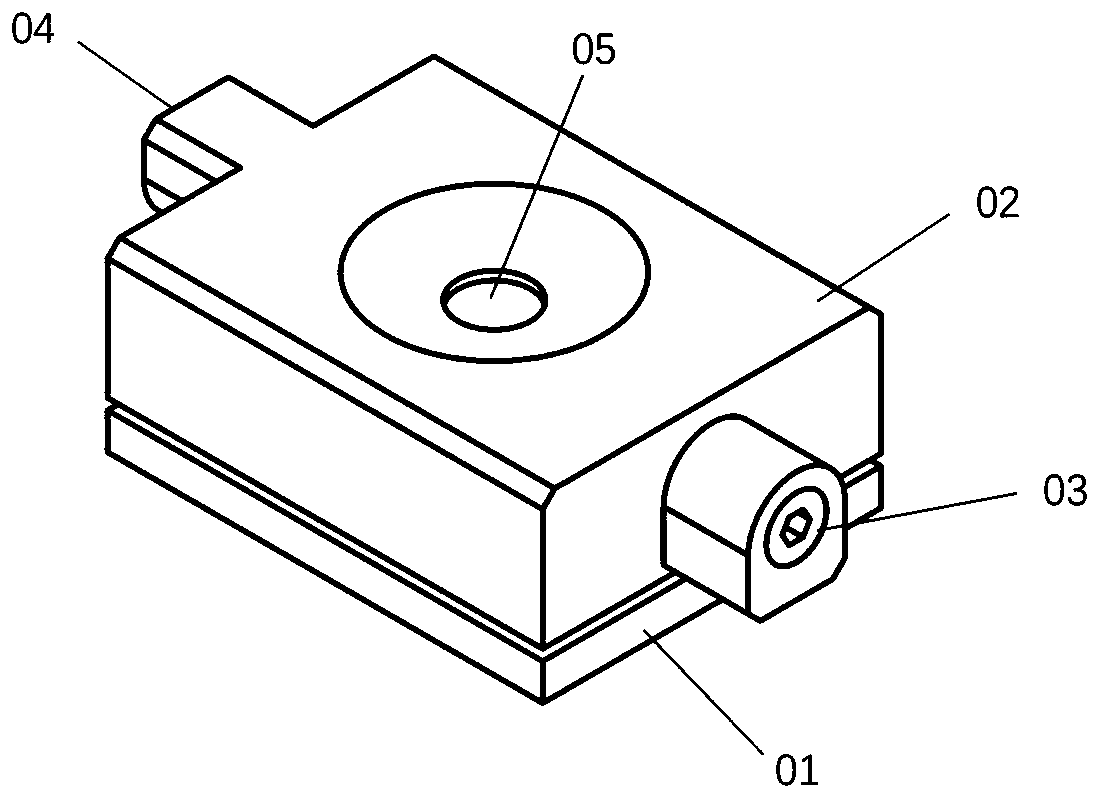

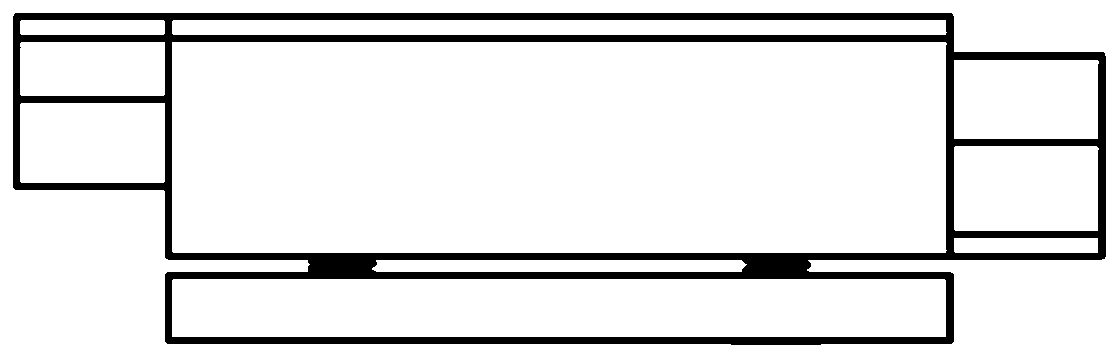

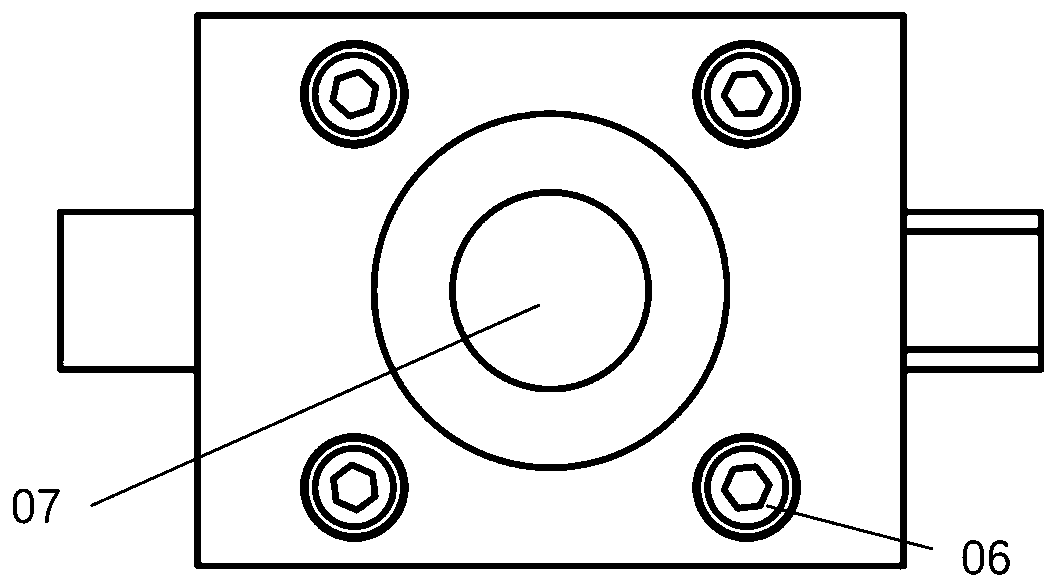

[0023] like figure 1 and figure 2 As shown, the test device involved in the present invention is composed of a base 01 and a main body 02. The main body 02 of the test box has electrode interfaces 03, 04 on both sides, and both interfaces have cylindrical or hexagonal column grooves inside, which are used to communicate with other Equipped with banana plugs for connection, banana plugs and external electrochemical workstation connection for precise control of current and voltage. like image 3 and Figure 4 As shown, a window 05 is opened on the top of the main body 02, and a window 07 is opened on the base, so that photons / neutrons can pass therethrough and used to collect test signals in transmission mode. like Figure 5 As shown, the various components of the device involved in the present invention are sealed by a sealing ring. The material to be tested is fixed between the electrode fixing plates 09 and 10 ( Image 6 , Figure 7 ), put it into the sealed test cavi...

Embodiment 2

[0026] Two gas channels can be opened at both ends of the device of the present invention, and the in-situ transmission mode research is carried out on the charging and discharging process of the tested material under a specific atmosphere. When in use, install the device and open the gas inlet and outlet as described in Example 1.

Embodiment 3

[0028] The device of the invention can provide a protective environment for materials sensitive to air or moisture, and is suitable for long-time transmission mode optical research on materials under non-electrochemical conditions. For use, the device can be installed as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com