Phosphating process for steel pipe

A process and steel pipe technology, which is applied in the phosphating process of steel pipes, can solve the problems of high temperature in the processing workshop, large energy consumption, and harsh working environment for the staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

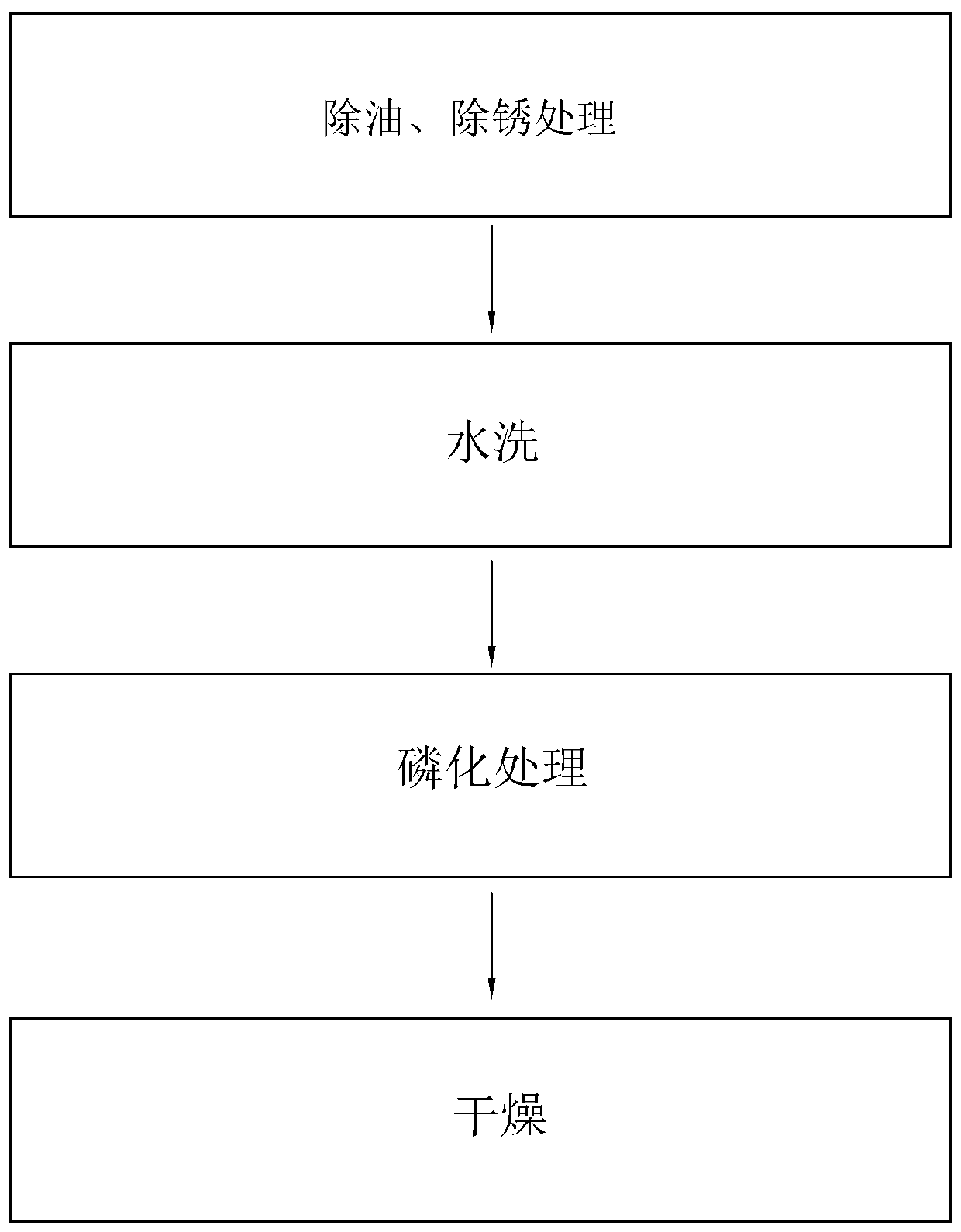

[0042] A phosphating process for steel pipes, such as figure 1 shown, including the following steps:

[0043] S1, degreasing and derusting treatment;

[0044] S2, washing with water;

[0045] S3, phosphating treatment;

[0046] S4, dry;

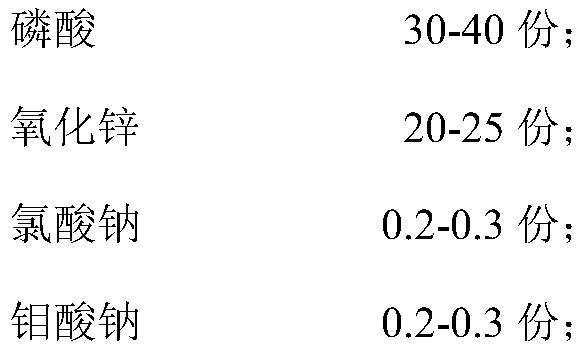

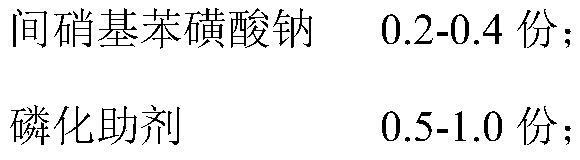

[0047] In terms of parts by weight, the components of each liter of phosphating solution are shown in Table 1, and the pH is adjusted to 2.0 with ammonia water.

[0048] Wherein, the phosphating aid adopts citric acid.

Embodiment 2

[0050] The difference from Example 1 is that, in terms of parts by weight, the components of each liter of phosphating solution are shown in Table 1, and ammonia water is used to adjust the pH to 3.0.

Embodiment 3

[0052] The difference from Example 1 is that, in terms of parts by weight, the components of each liter of the phosphating solution are shown in Table 1, and ammonia water is used to adjust the pH to 3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com