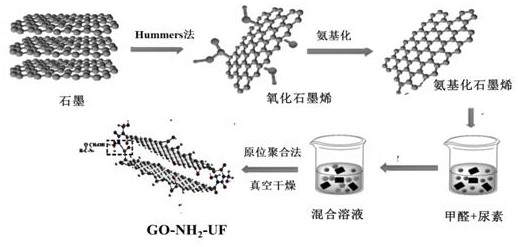

Method for preparing environment-friendly adhesive by aminated graphene modified urea-formaldehyde resin

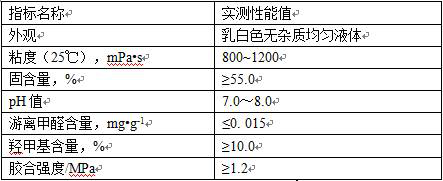

A technology of aminated graphene and urea-formaldehyde resin, which is applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems such as the decline in the strength and performance of the board, and achieve improved bonding strength and reduced formaldehyde content , The effect of reducing the release of free formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

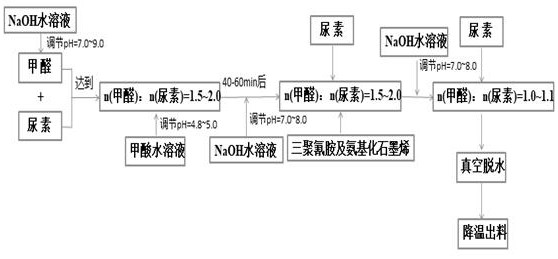

Method used

Image

Examples

Embodiment

[0019] S1. Preparation of graphene oxide: Add 3g of natural graphite and 1.5g of sodium nitrate to 70mL of concentrated H at 2 SO 4 After electric stirring for 40min, slowly add 9gKMnO 4 (add within 1.5h), and keep the temperature below 20°C with an ice-water bath; after 30 minutes of reaction, raise the temperature of the system to 40°C and stir for 30 minutes, slowly add 200mL of distilled water to the system, continue to rise to 98°C and stir for 15 minutes , the system was lowered to room temperature and poured into 400 mL of deionized water, and 30% H 2 o 2 until the solution is golden, let it stand for 12 hours, filter and centrifuge, wash the remaining solid with 5% HCL and distilled water until the pH is 7, and then dry the obtained sample at 70°C to obtain graphite oxide;

[0020] S2. Preparation of aminated graphene: Add 200 mg of graphite oxide into a three-neck flask equipped with 100 mL of DMF, mechanically stir at room temperature for 91 h, then add 36 mL of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com