Silicon-containing ultraviolet absorber, and preparation method of polyurethane copolymer thereof

A technology of UV absorbers and copolymers, which is applied in the field of preparation of silicon-containing UV absorbers and their polyurethane copolymers. It can solve problems such as single functionality, unsatisfactory requirements, and single functionality, so as to achieve difficult phase separation and enhanced stability. Sexuality, the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

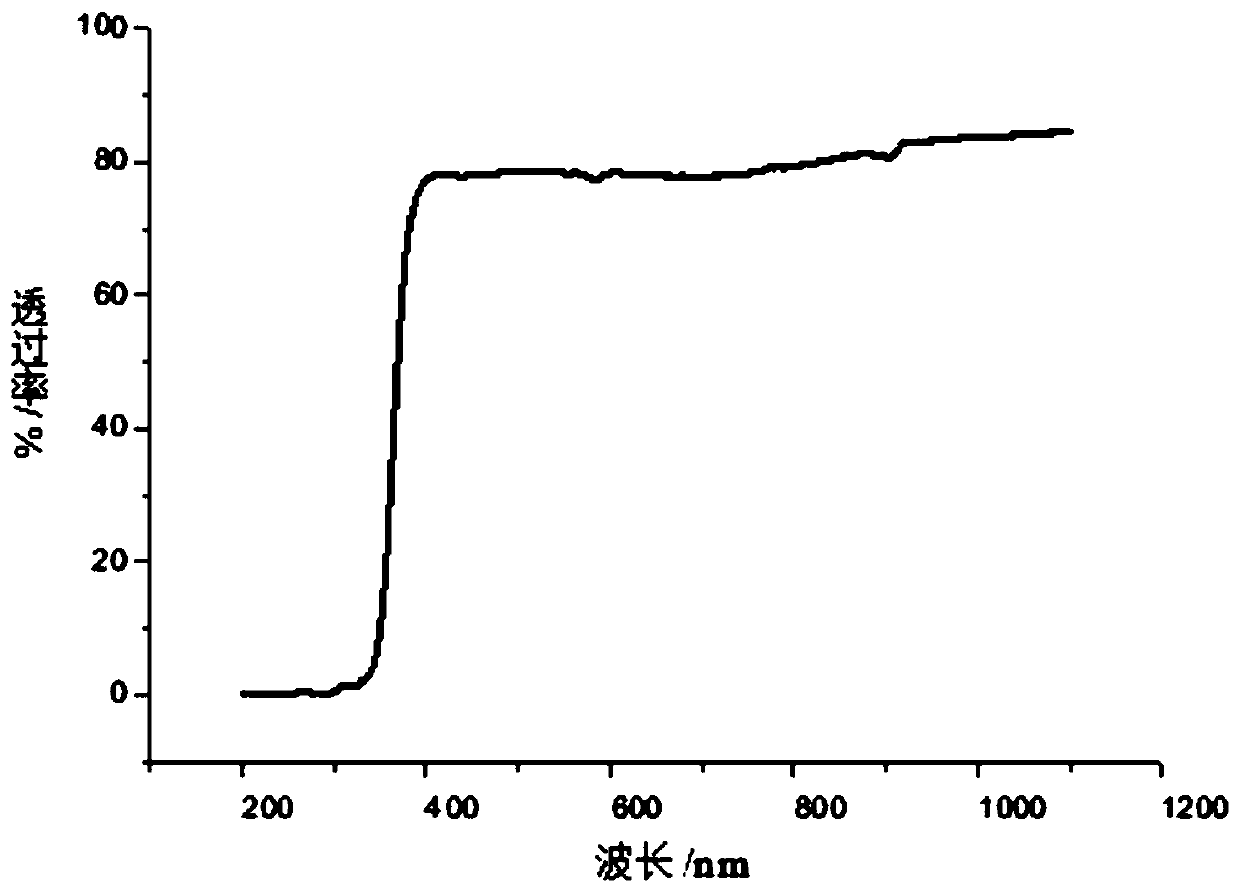

Embodiment 1

[0029] (1) The preparation method of silicon-containing ultraviolet absorber:

[0030] Mix 0.5mmol of 4-methylphenyl(2,4,6-trihydroxy-3(3-hydroxy-3-methylbutyl)phenyl)methanone and 3mmol of diisopropylethylamine and add 5mL of water 1,2-dichloroethane and 0.2 mmol di-tert-butyltin dichloride. After stirring evenly, react at 50°C for 15 minutes and cool to room temperature, then slowly add 0.8 mmol triisopropylsilyloxymethane chloride dropwise, and continue stirring for 1.5 hours. Then it was quenched with 1 mL of methanol, diluted with 0.5 mL of dichloromethane, and extracted twice with 10 mL of 0.03 mol / L sodium bicarbonate solution and water. The organic layers were combined, dried with Na2SO4 for 12 h, filtered and concentrated to remove the reaction solvent to obtain a silicon-containing ultraviolet absorber.

[0031] (2) The preparation method of polyurethane copolymer:

[0032] After adding 0.5mmol polypropylene glycol in the reactor, add dropwise 0.1mmol isophorone d...

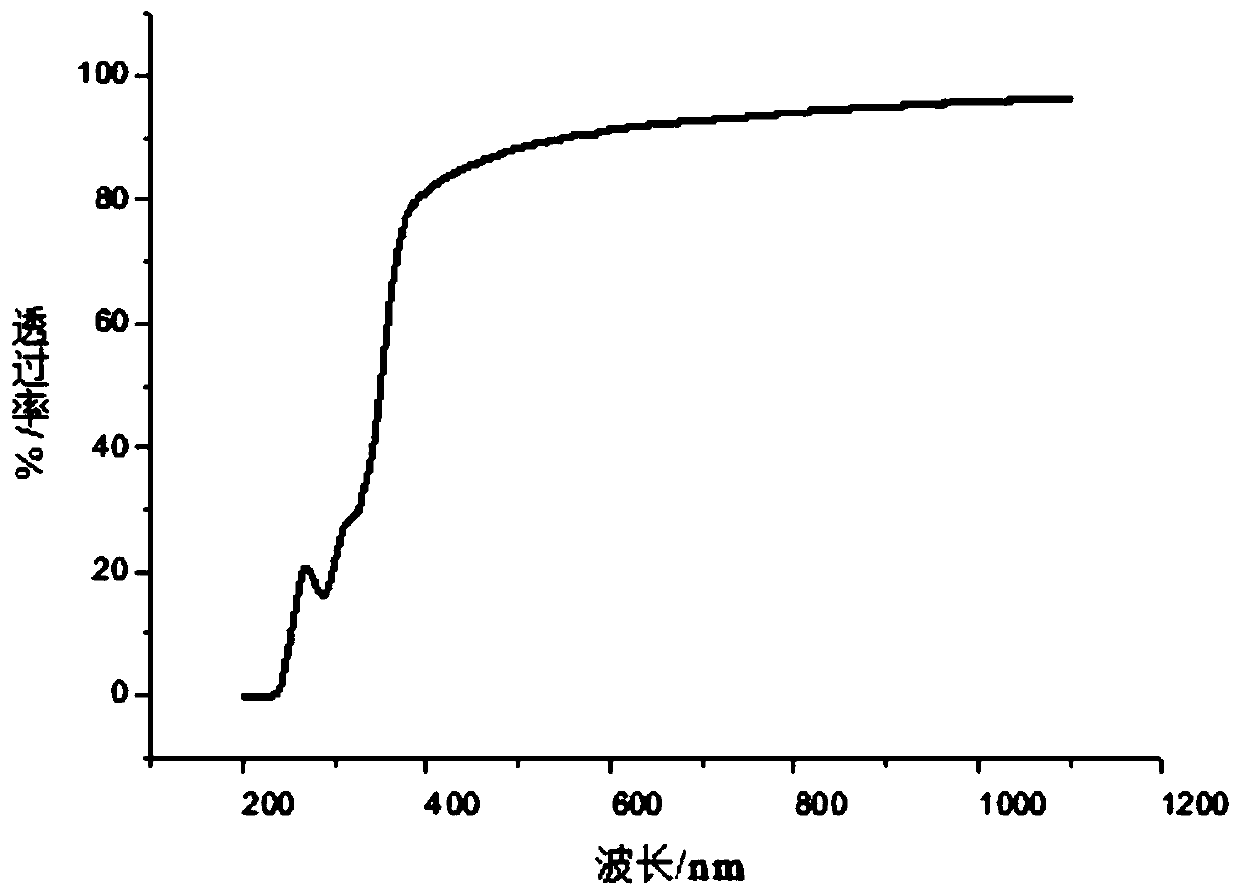

Embodiment 2

[0034] (1) The preparation method of silicon-containing ultraviolet absorber:

[0035] Mix 2mmol of 4-ethylphenyl (2,4,6-trihydroxy-3(3-hydroxy-3-methylbutyl)phenyl)methanone and 10mmol of diisopropylethylamine and add 7mL of water 1,3-dichloropropane and 0.5 mmol di-tert-butyltin dichloride. After stirring evenly, react at 60° C. for 30 minutes, then cool to room temperature, then slowly add 1.2 mmol of triisomethylsiloxymethane chloride dropwise, and continue stirring for 3 hours. Then, it was quenched with 3 mL of methanol, diluted with 1.3 mL of dichloromethane, and extracted twice with 50 mL of 0.05 mol / L sodium bicarbonate solution and water. The organic layers were combined, dried with Na2SO4 for 15 h, filtered and concentrated to remove the reaction solvent to obtain a silicon-containing ultraviolet absorber.

[0036] (2) The preparation method of polyurethane copolymer:

[0037] After adding 9mmol polyethylene glycol in the reactor, 2.3mmol toluene diisocyanate and...

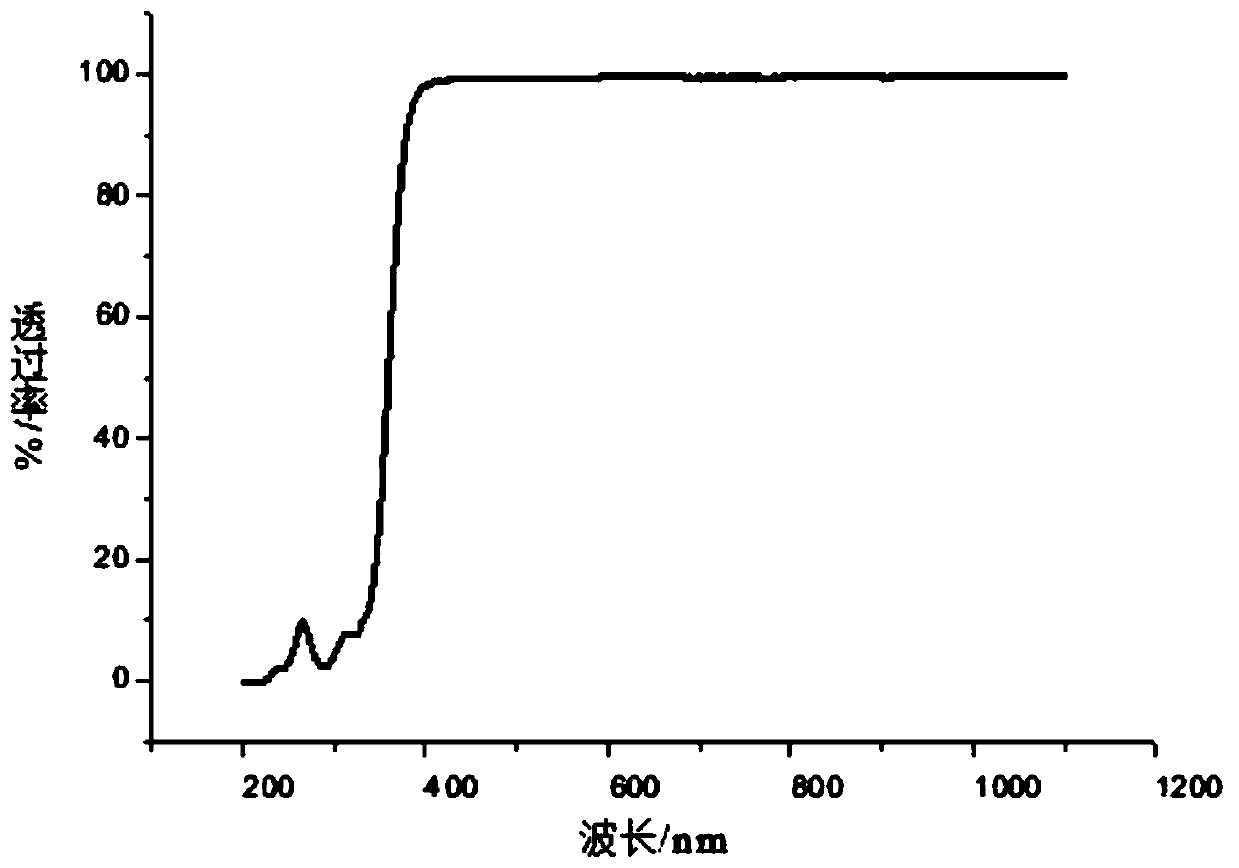

Embodiment 3

[0039] (1) The preparation method of silicon-containing ultraviolet absorber:

[0040] Mix 8mmol of 4-propylphenyl (2,4,6-trihydroxy-3(3-hydroxy-3-methylbutyl)phenyl)methanone and 26mmol of diisopropylethylamine and add 12mL of Water 1-chlorobutane and 3.6 mmol di-tert-butyltin dichloride. After stirring evenly, react at 65° C. for 45 minutes and cool to room temperature, then slowly add 2.7 mmol triisoethylsiloxymethane chloride dropwise, and continue stirring for 5 hours. Then, it was quenched with 6 mL of methanol, diluted with 4.8 mL of dichloromethane, and extracted three times with 120 mL of 0.08 mol / L sodium bicarbonate solution and water. The organic layers were combined, dried with Na2SO4 for 20 h, filtered and then concentrated to remove the reaction solvent to obtain a silicon-containing ultraviolet absorber.

[0041] (2) The preparation method of polyurethane copolymer:

[0042] After adding 13.5mmol of polytetrahydrofuran diol in the reactor, 14.5mmol of hexame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com