Method for improving bonding strength of anti-oxidation coating on surface of carbon-based or ceramic-based composite material

A technology of anti-oxidation coating and composite materials, which is applied in the field of improving the bonding strength of anti-oxidation coatings on the surface of carbon-based or ceramic-based composite materials, which can solve the problems of easy peeling, rapid consumption, and low bonding strength of coatings, and achieve small damage , Improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

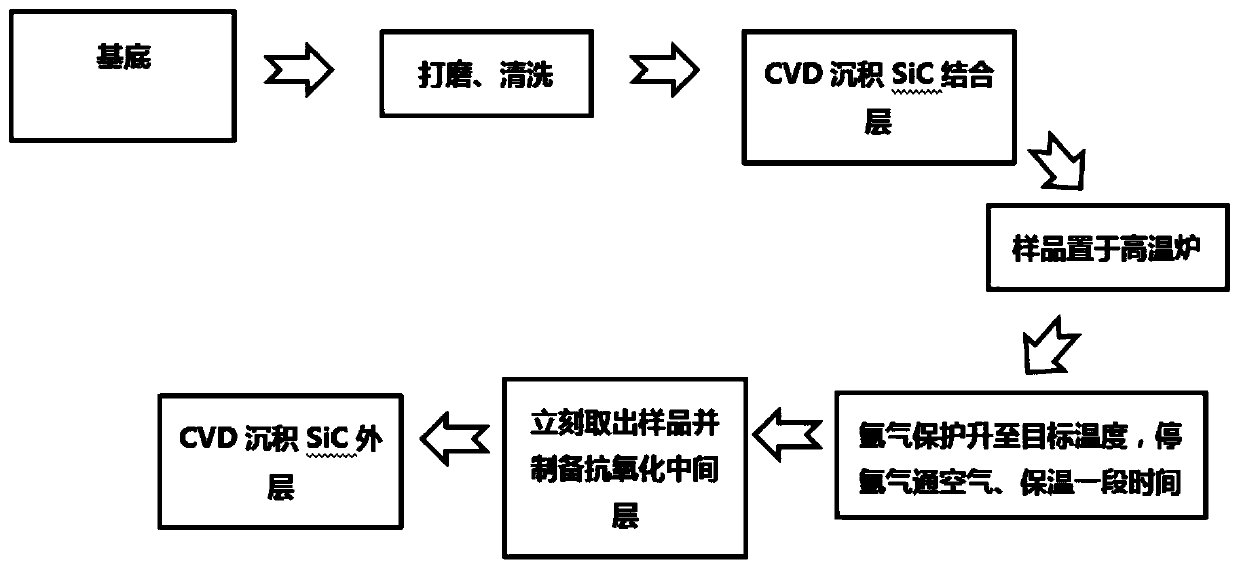

[0031] The process flow chart for improving the bonding strength of the anti-oxidation coating on the surface of the ceramic matrix composite material in this embodiment is as follows figure 1 As shown, the specific process is as follows:

[0032] First to C f / SiC samples were pretreated. Choose a density of 2.0g / cm 3 C f / SiC, polished with 400# diamond sandpaper, ultrasonically oscillated in distilled water for 80 minutes, and then rinsed repeatedly with distilled water; the cleaned C f / SiC was dried at 150°C for 24 hours for later use.

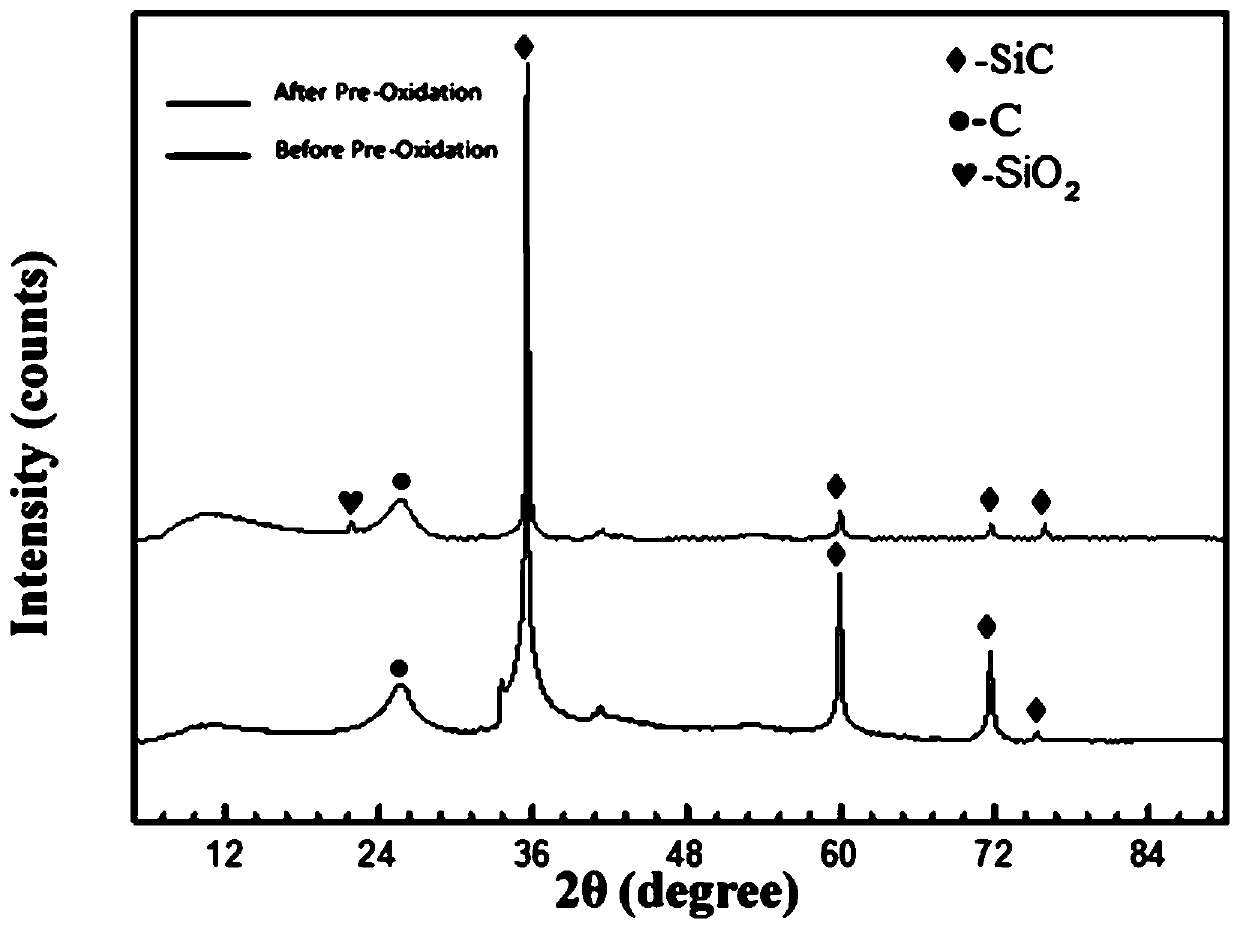

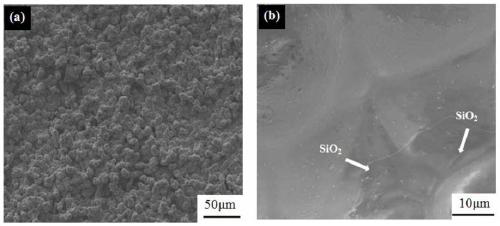

[0033] The preprocessed C f / SiC samples are placed in a graphite crucible and placed in a chemical vapor deposition furnace to deposit the SiC bonding layer. A small hole is drilled at the bottom of the graphite crucible to ensure gas circulation. The deposition temperature is 1100°C, the deposition pressure is 5mmHg, the flow rate of trichloromethylsilane (MTS) is 60g / h, and the flow rate of hydrogen gas is 0.03m 3 / h, argon flow r...

Embodiment 2

[0041] First to C f / C samples were pretreated. Choose a density of 1.9g / cm 3 C f / C, after polishing with 600# silicon carbide sandpaper, ultrasonically vibrate in distilled water for 70min, and then rinse repeatedly with distilled water; the cleaned C f / C at 150°C, dry for 24 hours for later use.

[0042] The preprocessed C f The / C sample is placed in a graphite crucible and placed in a chemical vapor deposition furnace for SiC bonding layer deposition. A small hole is drilled at the bottom of the graphite crucible to ensure gas circulation. The deposition temperature is 1000°C, the deposition pressure is 6mmHg, the flow rate of trichloromethylsilane (MTS) is 70g / h, and the flow rate of hydrogen gas is 0.04m 3 / h, argon flow rate 0.05m 3 / h. Take it out after 15 hours of deposition, turn it over and deposit it for another 15 hours. Increase the deposition temperature to 1100°C, and the hydrogen flow rate to 0.08m 3 / h, argon flow rate 0.1m 3 / h, after 20h of depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com