Energy-saving electromagnetic induction heating method and apparatus for carbonization treatment of organic solid waste

A technology of electromagnetic induction heating and organic solid waste, which is applied in the direction of pyrolysis treatment of sludge, energy input, special form of dry distillation, etc., to achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the drawings and specific embodiments.

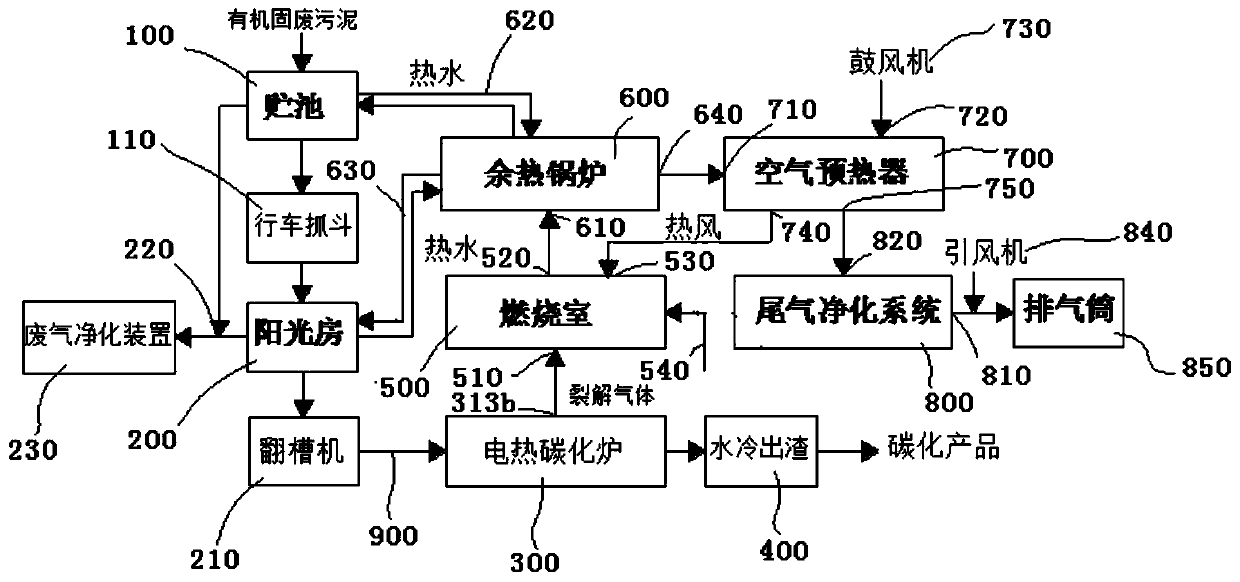

[0042] See figure 1 , The energy-saving electromagnetic induction heating organic solid waste disposal device shown in the figure includes a sludge storage tank 100, a crane grab 110, a sun room 200, a tank turning machine 210, an electric carbonization furnace 300, a water-cooled slagging device 400, and combustion Room 500, waste heat boiler 600, air preheater 700 and exhaust gas purification system 800. The sludge storage tank 100 is used to store organic solid waste sludge, and is connected to the sun room 200. A groove (not shown in the figure) is provided in the sun room 200, and the tail of the groove is connected to the electric carbonization furnace 300 through a belt conveyor 900 with a hopper, wherein the hopper is connected to the tail of the groove.

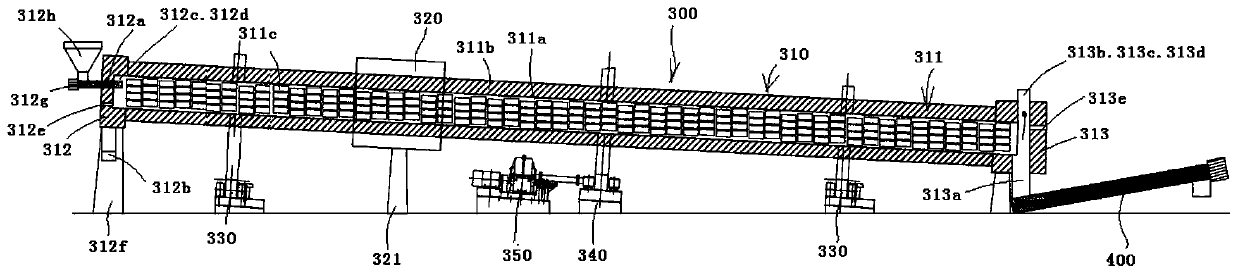

[0043] A groove turning machine track is arranged in the groove, and a groove turning machine 210 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com