High-temperature-resistant solder capable of being used for welding gamma-tial alloy and welding process thereof

A brazing process and high-temperature-resistant technology, which is applied in the field of welding manufacturing, can solve the problems of lack of high-strength and high-temperature solder brazing technology for high-strength and temperature-resistant joints, and achieve the effect of avoiding damage to the matrix structure and improving the diffusion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

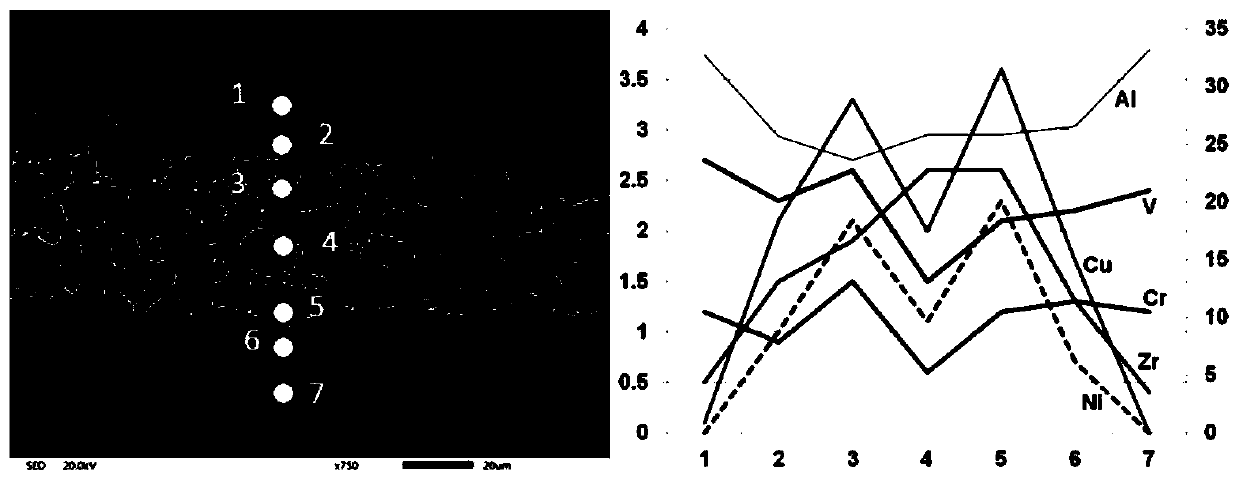

Embodiment 1

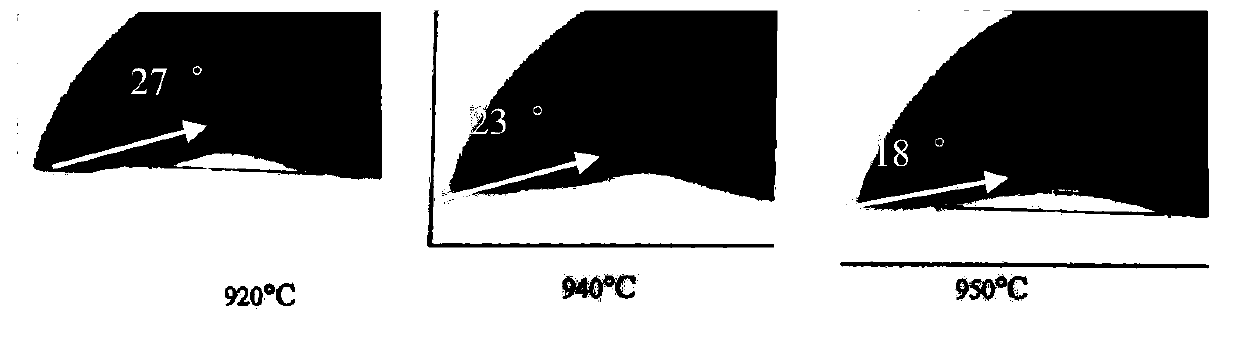

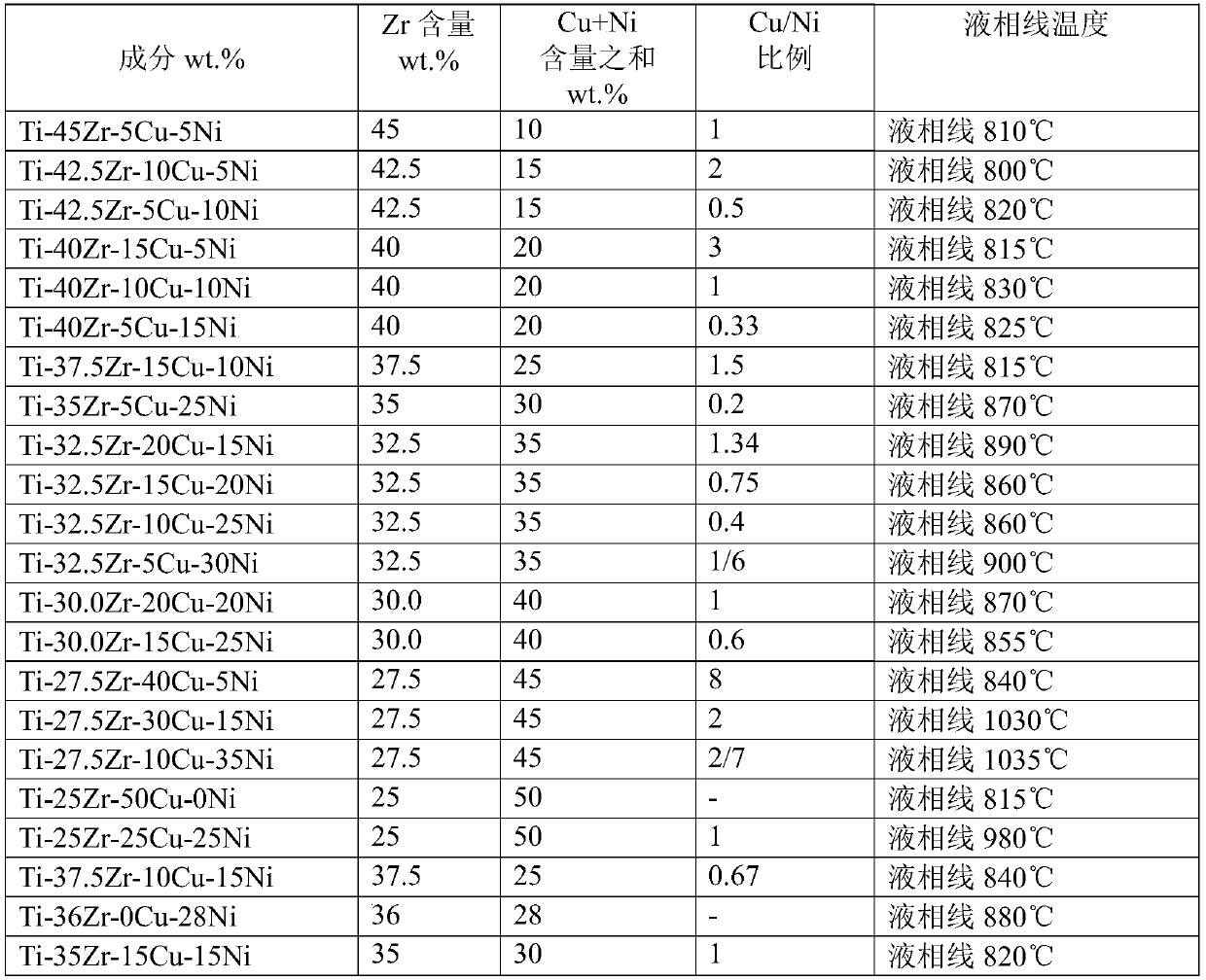

[0054] Select the composition of Ti-8Zr-10Cu-15Ni wt.% to prepare solder master alloy ingots and strips to obtain solder foils with a thickness of 0.028-0.030mm; position the foils on one side of the material to be welded by spot welding On the surface to be welded, the assembly of the materials to be connected on both sides is completed by positioning sheets or tooling. Using a vacuum brazing furnace, the welding temperature is 935°C, the holding time is 45min, and the vacuum degree is 10 -3 Pa~10 -5 Pa, welding gap 0.1mm; room temperature rises to 600°C corresponding to a heating rate of 85°C / min, from 600°C to 930-950°C corresponds to a heating rate of 120°C / min, and the cooling rate after heat preservation is 65°C / min min. The tensile strength of the obtained TiAl alloy connection joint at room temperature is 520MPa, reaching 95.4% of the strength of the matrix material; the tensile strength of the joint at 700°C is 410MPa, maintaining 78.8% of the joint strength at room...

Embodiment 2

[0056] Select the composition of Ti-9Zr-12Cu-14Ni wt.% to prepare solder master alloy ingots and strips to obtain solder foils with a thickness of 0.035-0.040mm; position the foils on one side of the material to be welded by spot welding On the surface to be welded, the assembly of the materials to be connected on both sides is completed by positioning sheets or tooling. Using a vacuum brazing furnace, the welding temperature is 940 ° C, the holding time is 50 minutes, and the vacuum degree is 10 -3 Pa~10 -5Pa, welding gap 0.07mm; room temperature rises to 600°C corresponding to a heating rate of 80°C / min, from 600°C to 930-950°C corresponds to a heating rate of 100°C / min, and the cooling rate after heat preservation is 70°C / min min. The tensile strength of the obtained TiAl alloy connection joint at room temperature is 540MPa, reaching 99.0% of the strength of the matrix material; the tensile strength of the joint at 700°C is 445MPa, maintaining 82.4% of the strength of the...

Embodiment 3

[0058] Select the composition of Ti-10Zr-15Cu-10Ni wt.% to prepare solder master alloy ingots and strips to obtain solder foils with a thickness of 0.05-0.055mm; position the foils on one side of the material to be welded by spot welding On the surface to be welded, the assembly of the materials to be connected on both sides is completed by positioning sheets or tooling. Using a vacuum brazing furnace, the welding temperature is 950 ° C, the holding time is 30 minutes, and the vacuum degree is 10 -3 Pa~10 -5 Pa, welding gap 0.04mm; room temperature rises to 600°C corresponding to a heating rate of 90°C / min, from 600°C to 930-950°C corresponds to a heating rate of 110°C / min, and the cooling rate after heat preservation is 80°C / min min. The room temperature tensile strength of the obtained TiAl alloy connection joint is 545MPa, which is as strong as the base material; the tensile strength of the joint at 700°C is 418MPa, which maintains 76.7% of the joint strength at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength at room temperature | aaaaa | aaaaa |

| Tensile strength at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com