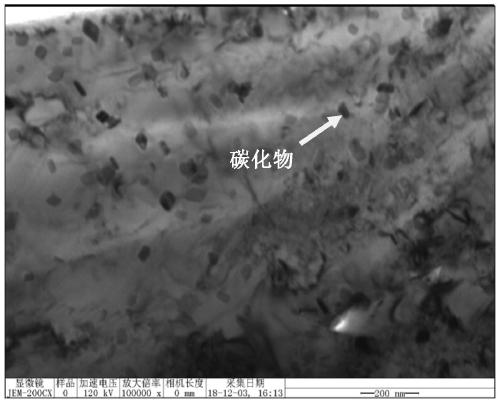

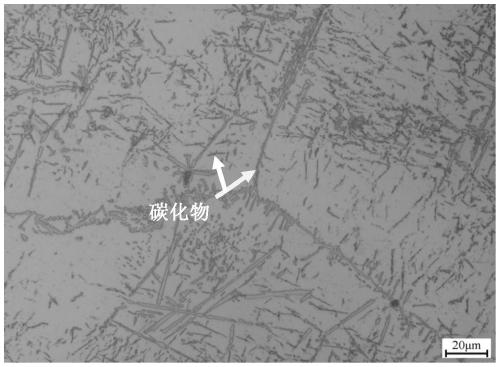

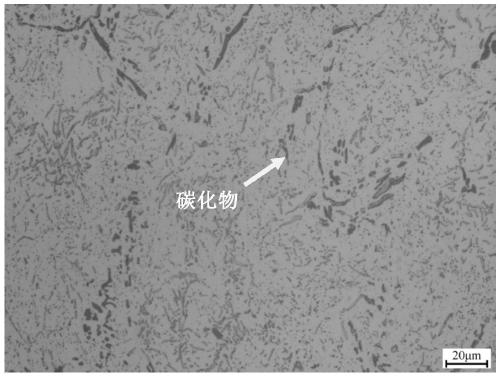

Preparation method for medium- and high-strength niobium alloy powder with intracrystalline-strengthened nano-scale carbide

A carbide and niobium alloy technology is applied in the field of preparation of nano-carbide intragranular strengthening type medium and high-strength niobium alloy powder, which can solve problems such as inability to achieve, and achieve the effects of improving strengthening effect, improving uniformity and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] Step 1. Put 2.2kg of FNbC-1 powder with a specification of 30 into the planetary ball mill in batches, and run it at a speed of 1000r / min for 1h to obtain niobium carbide powder with a Fischer average particle size of 0.08μm. Put 2kg of FNbC-1 powder with a specification of 30 The FNbC-1 powder was put into the planetary ball mill in batches and operated at a speed of 1200r / min for 1h to obtain niobium carbide powder with a Fischer average particle size of 0.08μm, and then the above two sources of niobium carbide powder were mixed with 78.8kg of Nb1 powder, 10kg of FW-1 powder, 5.3kg of FMo-1 powder, 1.7kg of ZrH 2 The powder is put into the ball mill cylinder of the rolling ball mill (the inner diameter of the ball mill cylinder is 600 mm), and then 200 kg of hard alloy ball milling balls with a diameter of 15 mm and 2500 mL of absolute ethanol are added, and the rotating speed of the ball mill cylinder is adjusted...

Embodiment 2

[0069] This embodiment includes the following steps:

[0070] Step 1. Mix 4.1kg of FNbC-2 powder with a specification of 10, 78.5kg of Nb1 powder, 4.5kg of FW-1 powder, 11.7kg of FMo-1 powder, and 1.3kg of ZrH 2 Put the powder into the ball mill cylinder of the rolling ball mill (the inner diameter of the ball mill cylinder is 600mm), then add 200kg of cemented carbide balls with a diameter of 15mm and 1800mL of gasoline, adjust the speed of the ball mill cylinder to 48r / min for rolling ball milling for 48h, and let stand for 16h After taking out to obtain ball mill powder;

[0071] Step 2. Put the ball-milled powder obtained in Step 1 into a vacuum dryer, and vacuum-dry it at a temperature of 50°C to 140°C to obtain a medium-high-strength niobium alloy powder of a nano-carbide intragranular strengthening type; the nanometer The carbide intragranular strengthening type medium and high strength niobium alloy powder is composed of the following components in mass percentage: W ...

Embodiment 3

[0079] This embodiment includes the following steps:

[0080] Step 1. Mix 0.7kg of FNbC-3 powder with specification 15, 63.3kg of Nb1 powder, 30kg of FW-1 powder, 2.5kg of FMo-1 powder, and 3.5kg of ZrH 2 Put the powder into the ball milling cylinder of the rolling ball mill (the inner diameter of the ball milling cylinder is 600mm), then add 200kg of hard alloy balls with a diameter of 15mm and 1800mL of absolute ethanol, adjust the rotating speed of the ball milling cylinder to 48r / min and carry out rolling ball milling for 24h, statically Take out after putting for 12h and obtain ball mill powder;

[0081] Step 2. Put the ball-milled powder obtained in Step 1 into a vacuum dryer, and vacuum-dry it at a temperature of 50°C to 140°C to obtain a medium-high-strength niobium alloy powder of a nano-carbide intragranular strengthening type; the nanometer The carbide intragranular strengthened medium-high-strength niobium alloy powder is composed of the following components in ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com