Seabuckthorn juice beverage and preparation method thereof

A technology of seabuckthorn fruit juice and seabuckthorn fruit, which is applied in the field of beverages to achieve the effects of good taste, short preparation cycle and reduction of uncontrollable causes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

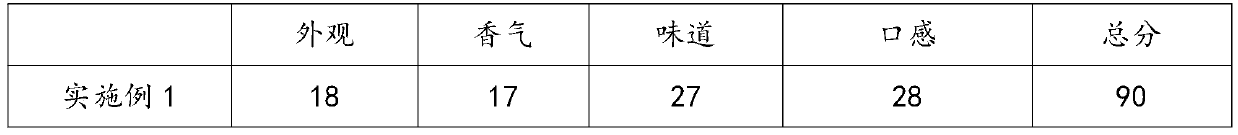

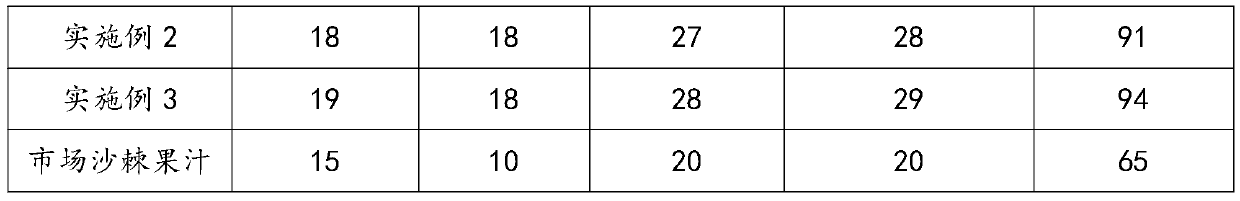

Embodiment 1

[0028] A preparation method of sea-buckthorn fruit juice drink is characterized in that it comprises the following steps:

[0029] (1) Product deployment: 40 parts of seabuckthorn fruit juice, 70 parts of purified water and 4 parts of fructose syrup are configured as product stock solution, and the solid content of the sea buckthorn fruit juice accounts for 10% of the total weight ratio, so The total acid of the original fruit juice of seabuckthorn fruit is 2%;

[0030] (2) compounding: then add 0.2 part of stabilizer to the product stock solution prepared in step (1), the stabilizer is sodium alginate and gelatin, add 1 part of white sugar, 0.02 part of potassium sorbate, 0.003 part of sodium citrate part, 0.015 part of stevioside, 0.002 part of sucralose, and 0.02 part of salt are stirred and heated in the configuration tank, and the heating temperature is 70 ° C. The temperature of the water is 55°C, then the stabilizer and sugar are stirred evenly, poured into the shearin...

Embodiment 2

[0038] A preparation method of sea-buckthorn fruit juice drink is characterized in that it comprises the following steps:

[0039] (1) Product deployment: 35 parts of sea-buckthorn fruit juice, 65 parts of purified water and 4 parts of high-fructose syrup are configured as a product stock solution, and the solid content of the sea-buckthorn fruit juice accounts for 12% of the total weight ratio. 3% total acid of raw sea buckthorn fruit juice;

[0040] (2) Compounding: Then add 0.2 parts of stabilizer to the product stock solution prepared in step (1), the stabilizer sodium alginate, gelatin, calcium chloride and carrageenan, add 1.5 parts of white sugar, 0.025 parts of potassium sorbate part, 0.01 part of sodium citrate, 0.018 part of stevioside, 0.004 part of sucralose, and 0.022 part of salt are stirred and heated in the configuration tank, the heating temperature is 70 ° C, and 20- 45 parts of water, then stir the stabilizer and sugar evenly, pour into the shearing tank, s...

Embodiment 3

[0048] (1) Product deployment: 40 parts of sea-buckthorn fruit juice, 70 parts of purified water and 5 parts of high-fructose syrup are configured as product stock solution, and the solid content of the sea-buckthorn fruit juice accounts for 12% of the total weight ratio, so The total acid 3% of the original fruit juice of seabuckthorn fruit;

[0049] (2) Compounding: Then add 0.2 parts of stabilizer to the product stock solution prepared in step (1), the stabilizer is gelatin, add 2 parts of white sugar, 0.03 parts of potassium sorbate, 0.015 parts of sodium citrate, stevioside 0.02 parts, 0.006 parts of sucralose, and 0.025 parts of salt are stirred and heated in the configuration tank, the heating temperature is 70 ° C, and 45 parts of water at 65 ° C are poured into the shear tank, so the stabilizer and white sugar Stir evenly, pour into the shear tank, shear for 25 minutes, then pour the rest of the ingredients into the shear tank;

[0050] (3) Coarse filtration: pass the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com