Antibacterial preservative film, and preparation method and applications thereof

A fresh-keeping film and a technology for its use are applied in the field of fresh-keeping films containing lauroyl arginine ethyl ester salt and derivatives thereof, and achieve the effects of simple preparation, good stability and easy biological catabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Preparation method of synthetic ion-pair compound of lauroyl arginine ethyl ester hydrochloride and nicotinic acid

[0065] Dissolve 2.0 g of sodium nicotinic acid (purchased from Tixiai (Shanghai) Chemical Industry Development Co., Ltd.) in 50 mL of water to prepare sodium nicotinic acid salt solution (A); 6.8 g of lauroyl arginine ethyl ester hydrochloride Dissolve in 40mL of water and heat to 90°C until all lauroyl arginine ethyl ester hydrochloride is dissolved to prepare an aqueous solution of lauroyl arginine ethyl ester hydrochloride (B); The saline solution (A) is slowly added to the lauroyl arginine ethyl ester hydrochloride solution (B), stirring constantly, reacting for 2 hours, cooling to room temperature, filtering, fully washing the precipitate with purified water, and drying the precipitate in vacuum at 60°C. 7.6 g of niacin ion pair compound is obtained.

Embodiment 2

[0066] Example 2: Analysis of the molecular formula and molecular weight of the compound of the nicotinic acid ion of ethyl lauroyl arginine

[0067] By mass spectrometry, 1 H-NMR, 13 The molecular formula of the compound obtained by C-NMR spectrum analysis is:

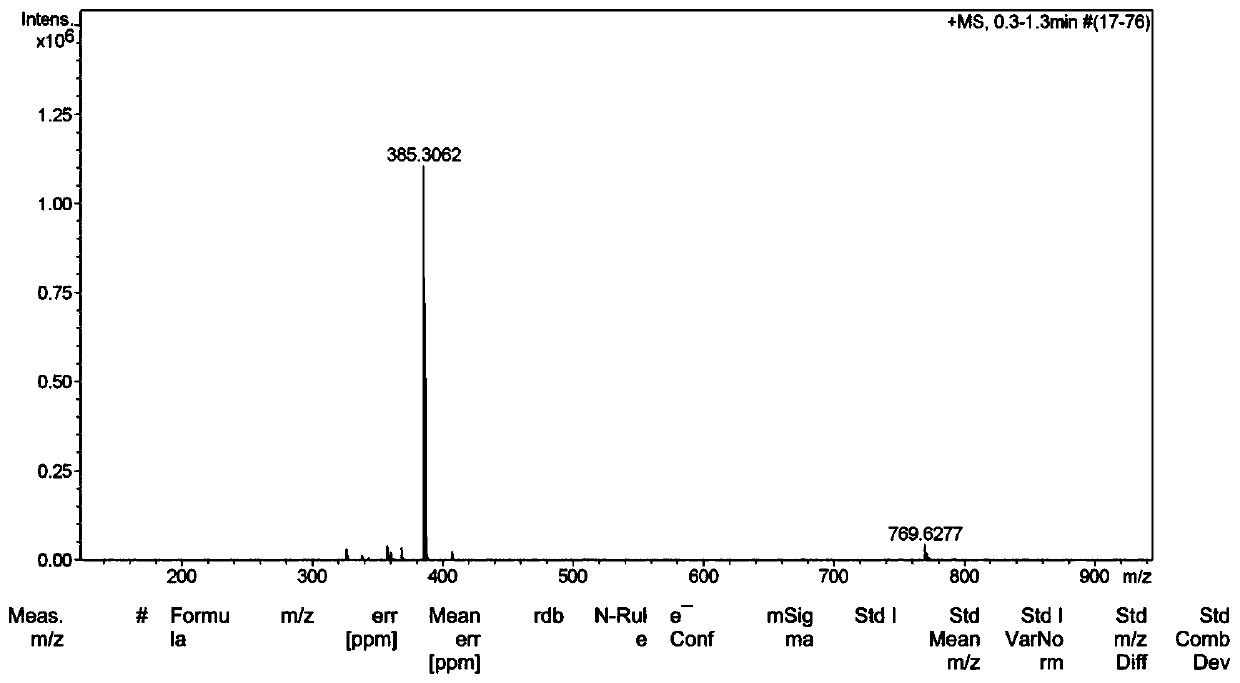

[0068] 1. Mass spectrometry (ESI) analysis

[0069] Cation B + The m / z of the molecular ion peak = 385.3, see figure 1 ;

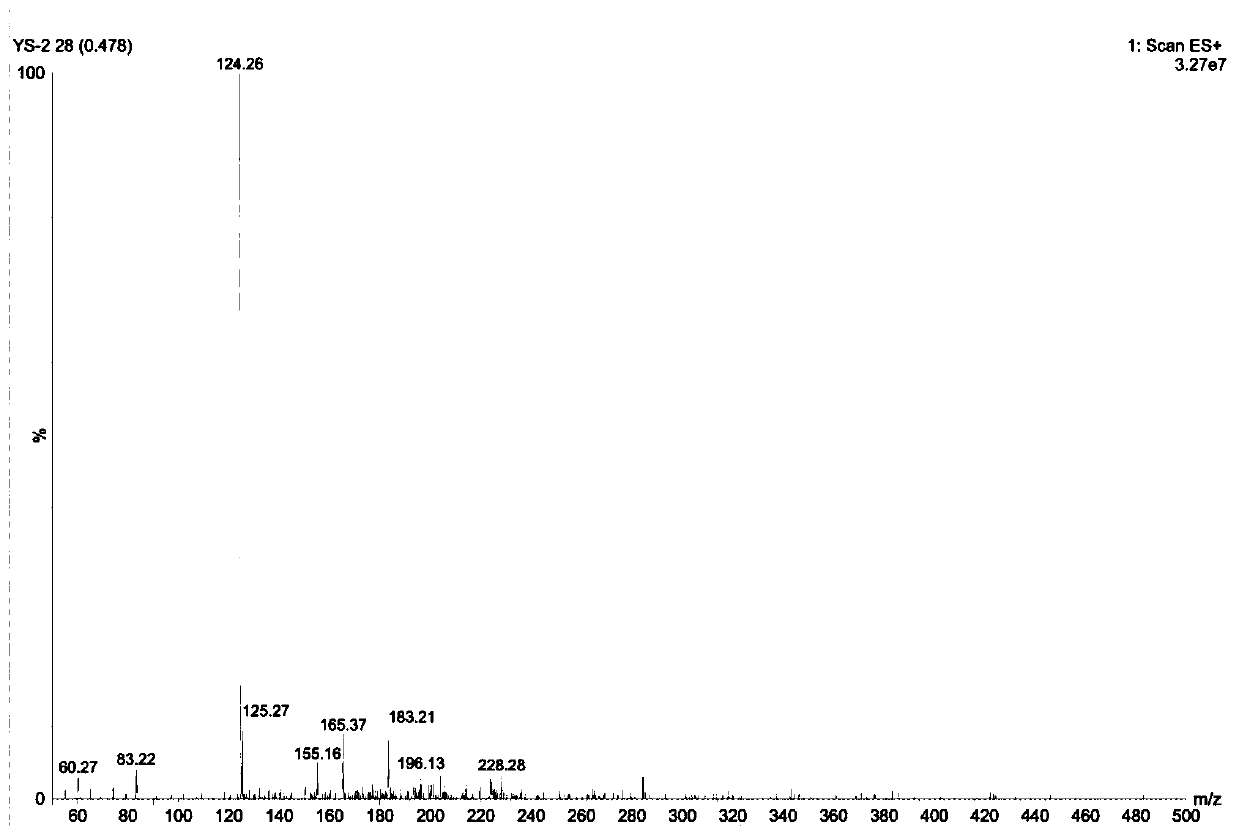

[0070] Anion A - The m / z of the molecular ion peak = 122.1, see figure 2 .

[0071] The theoretical calculated value of the cation of the niacin ion pair compound is 507.4, and the measured value is consistent with the theoretical value.

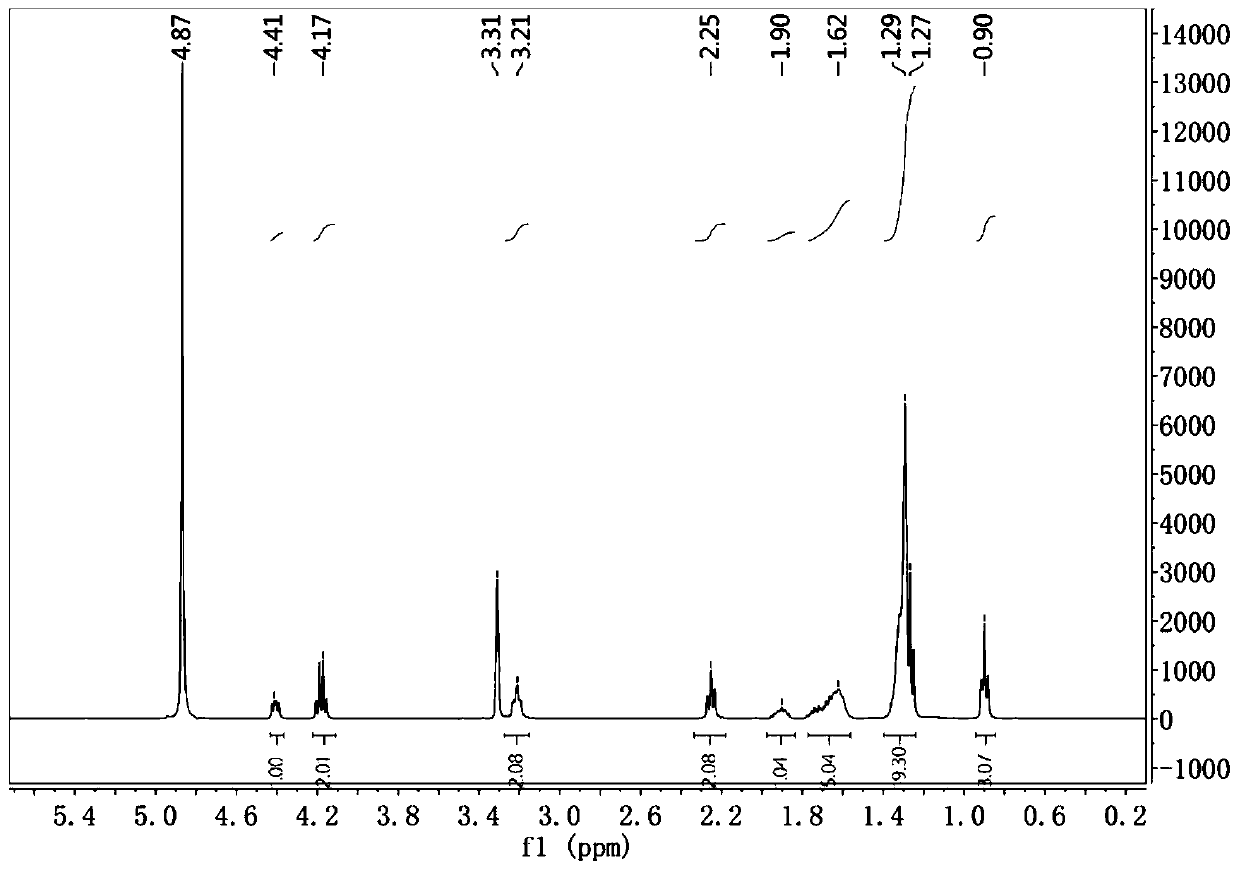

[0072] 2.NMR analysis

[0073] Lauroyl arginine ethyl ester hydrochloride (see image 3 ), niacin 1 H-NMR (see Figure 4 ) And LAE niacin ion pair compound 1 H-NMR (see Figure 5 )Compared. Since the LAE ion-pair compound is in the process of salt formation, the peak shape and chemical shift of the ion-pair compound of lauroyl arginine ethyl ester change little, but all h...

Embodiment 3

[0074] Example 3: Preparation method of synthetic ion-pair compound of lauroyl arginine ethyl ester hydrochloride and tartaric acid

[0075] Dissolve 2.0 g of tartaric acid (purchased from Tixiai (Shanghai) Chemical Industry Development Co., Ltd.) in 50 mL of methanol, add equivalent NaOH, stir at room temperature until a white solid precipitates, filter with suction and wash with 30 mL of methanol three times to obtain sodium tartrate . Sodium tartrate is dissolved in 50mL of water to prepare a sodium tartrate solution (A); 5.6 g of lauroyl arginine ethyl ester hydrochloride is dissolved in 40 mL of water and heated to 90°C until the lauroyl arginine ethyl ester salt The acid salt is completely dissolved to prepare an aqueous solution of lauroyl arginine ethyl ester hydrochloride (B); the sodium tartrate solution (A) is slowly added to the aqueous solution of lauroyl arginine ethyl ester hydrochloride ( In B), continue to stir, react for 2 hours, cool to room temperature, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com