Rotating device for multi-surface adhesive bonding of battery cell

A technology of rotating device and battery cells, which is applied in the manufacture of primary battery equipment, primary batteries, circuits, etc., can solve the problems of affecting the glue sticking effect of the battery cells, the stability of the mounting seat is not strong, and the clamping effect is not good, etc., to achieve Good gluing effect, high gluing efficiency, and reduced changing positions and positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

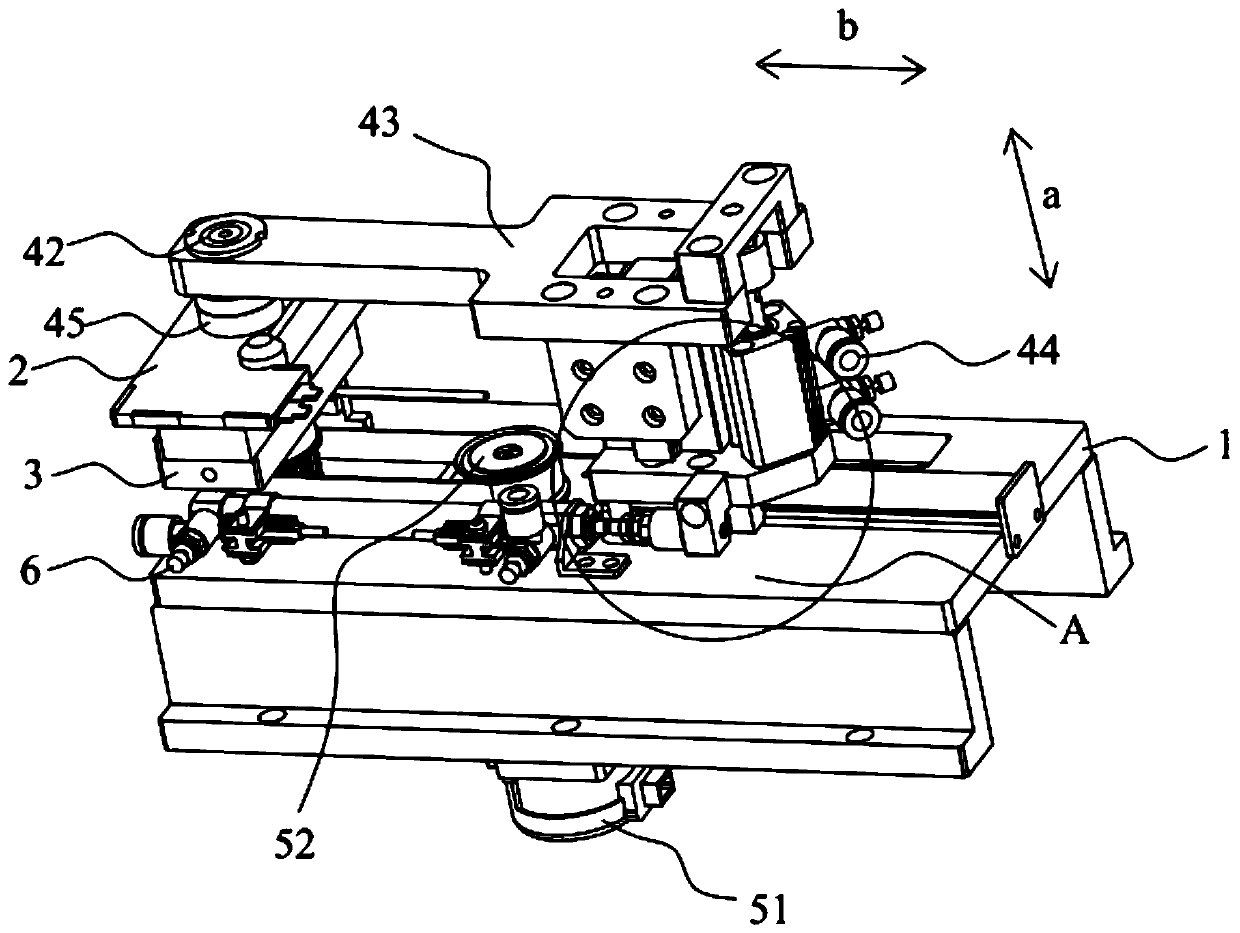

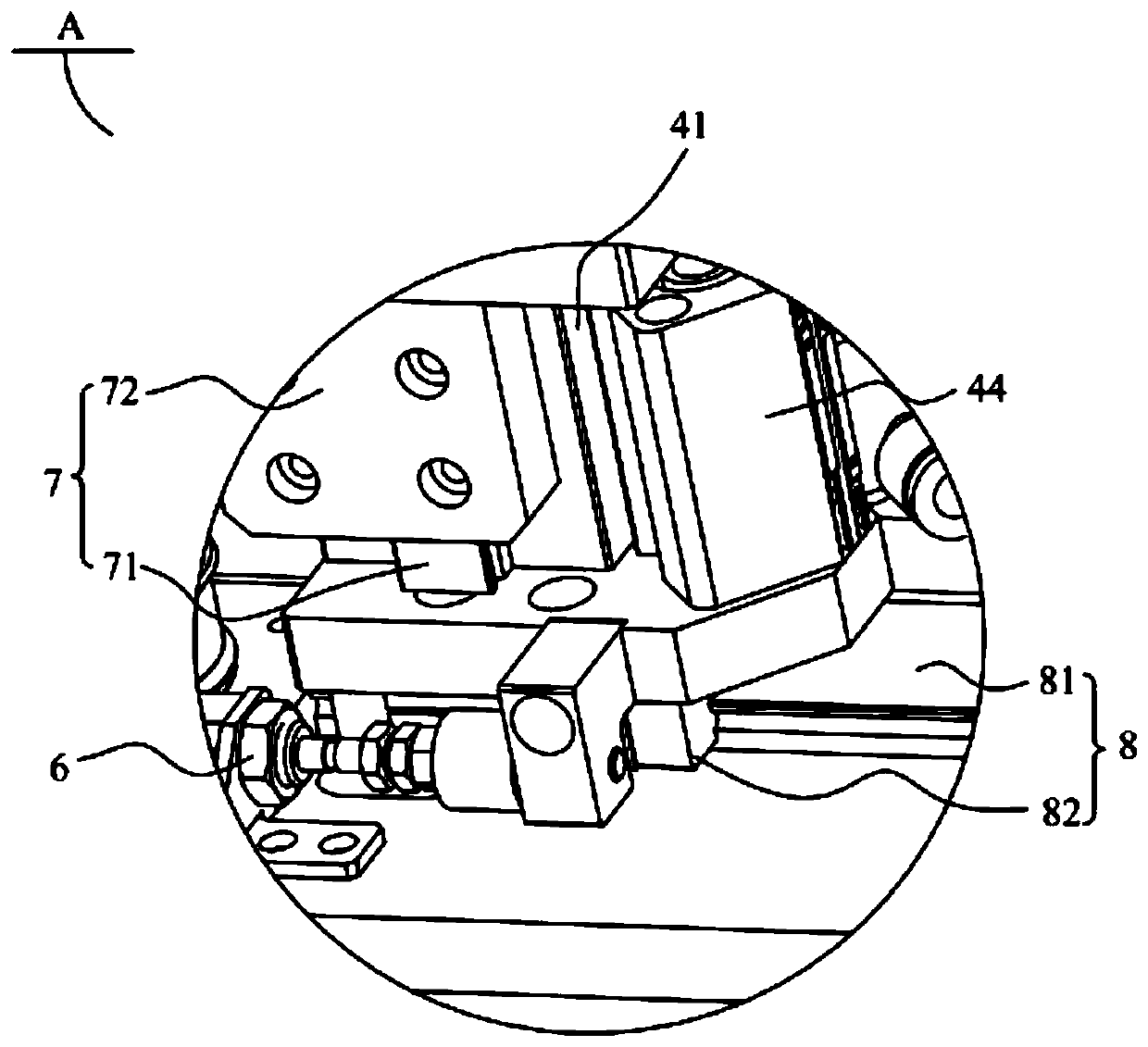

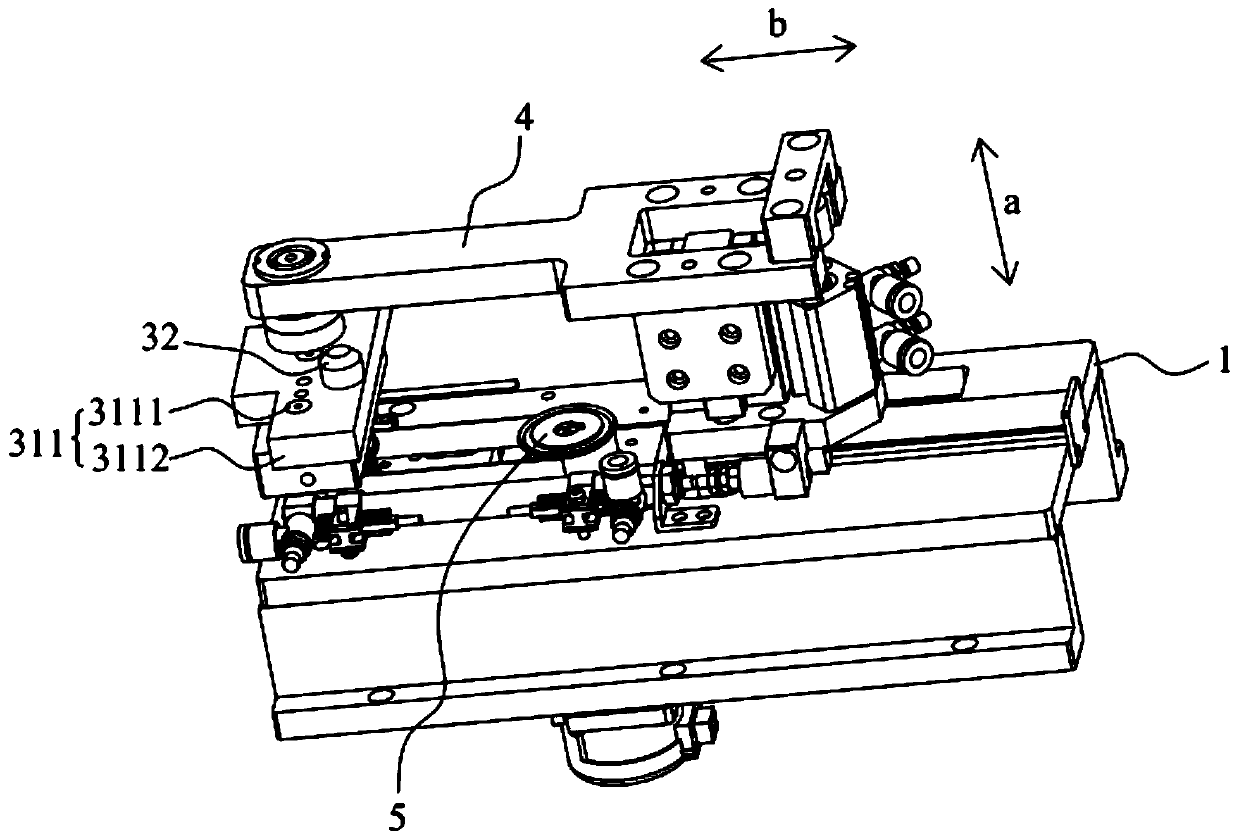

[0024] Refer below Figure 1 to Figure 5 The rotating device used for multi-faced gluing of the battery cell 2 according to the embodiment of the present invention is described.

[0025] Such as figure 1 As shown, the rotating device used in the present invention for multi-faced gluing of the electric core 2 includes a support base 3, a fixing mechanism 4 and a rotating drive mechanism 5, the support base 3 is used to support the electric core, and the fixing mechanism 4 includes a pressing mechanism that can freely rotate around the rotating shaft. The block 45 and the pressing block 45 are arranged on one side of the support base 3 for pressing and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com