Preparation method of super-hydrophobic electromagnetic shielding fabric

An electromagnetic shielding, super-hydrophobic technology, applied in the direction of plant fibers, textiles and papermaking, liquid-repellent fibers, etc., can solve the problems of reducing the air permeability of fabrics, cumbersome and complicated preparation processes, and polyaniline refractory and insoluble. The production process is simple and easy to operate, the experimental conditions are not demanding, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

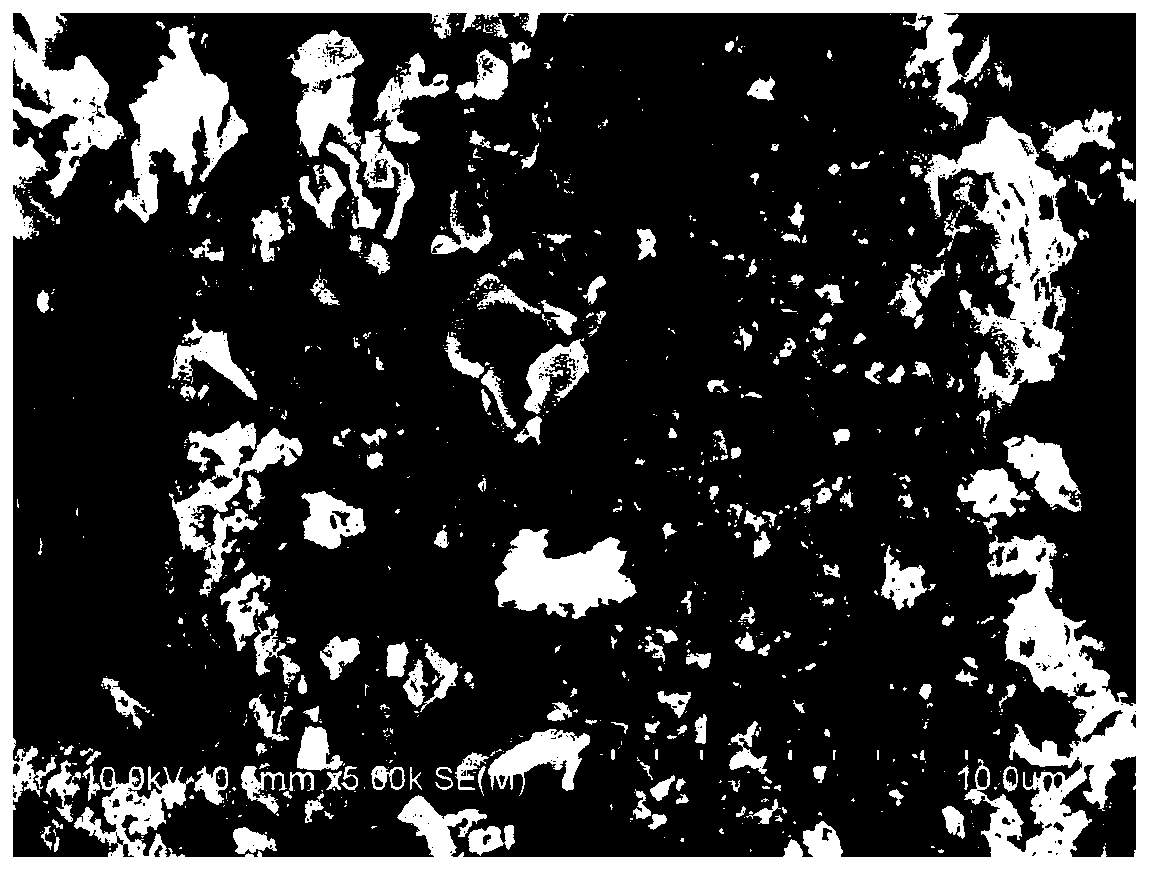

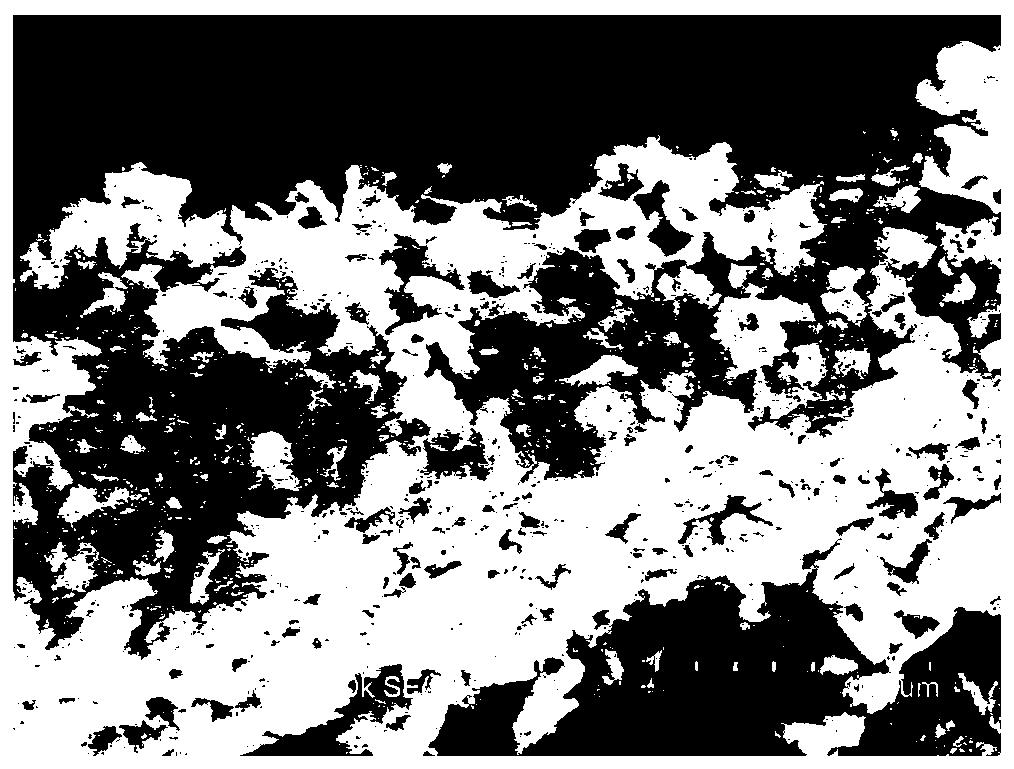

Image

Examples

Embodiment 1

[0037] Choose ordinary cotton fabric, cut the fabric with a size of 6cmx6cm, the thickness is about 0.415mm, the warp and weft density are 130 threads / 10cm and 100 threads / 10cm respectively, and the mass per unit area is 133g / ㎡. Follow the steps below to prepare superhydrophobic GO / PANI Coated cotton fabric.

[0038]Step 1. Wash the cotton fabric once with acetone, absolute ethanol and NaOH solution with a mass concentration of 15 g / L, and then wash it with deionized water to clean the fabric.

[0039] Step 2, immerse the cotton fabric in the reaction of 50g / L (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride solution and 18g / L sodium hydroxide solution to make cationization reagent solution for 15min, Take it out and keep 100% surplus rate. Leave the fabric at room temperature for 24 hours, then take it out, wash it with deionized water several times, and dry it for later use.

[0040] Step 3. Prepare a graphene oxide solution with a mass concentration of 0.4 g / L; put ...

Embodiment 2

[0049] The cotton fabric sample that present embodiment is selected with embodiment 1 is identical, and difference is that graphene oxide solution concentration parameter is different, and the concrete method of this embodiment is as follows:

[0050] Step 1. Wash the cotton fabric once with acetone, absolute ethanol and NaOH solution with a mass concentration of 15 g / L, and then wash it with deionized water to clean the fabric.

[0051] Step 2, immerse the cotton fabric in the reaction of 50g / L (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride solution and 18g / L sodium hydroxide solution to make cationization reagent solution for 15min, Take it out and keep 100% surplus rate. Leave the fabric at room temperature for 24 hours, then take it out, wash it with deionized water several times, and dry it for later use.

[0052] Step 3. Prepare a graphene oxide solution with a mass concentration of 0.6 g / L; put the solution into an ultrasonic cleaner to vibrate for 1 hour, then...

Embodiment 3

[0061] The cotton fabric sample selected in the present embodiment and embodiment 2 is identical, and difference is that the aniline solution concentration parameter is different, and the concrete implementation method of this embodiment is as follows:

[0062] Step 1. Wash the cotton fabric once with acetone, absolute ethanol and NaOH solution with a mass concentration of 15 g / L, and then wash it with deionized water to clean the fabric.

[0063] Step 2, immerse the cotton fabric in the reaction of 50g / L (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride solution and 18g / L sodium hydroxide solution to make cationization reagent solution for 15min, Take it out and maintain a 100% residual rate; take it out after standing at room temperature for 24 hours, wash it with deionized water for several times, and dry it for later use.

[0064] Step 3. Prepare a graphene oxide solution with a mass concentration of 0.6 g / L; put the solution into an ultrasonic cleaner to vibrate for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com