A method for chemically plating nickel-phosphorus alloy on the surface of beryllium aluminum alloy

A technology of beryllium aluminum alloy and surface chemistry, applied in the field of chemical plating process, can solve problems such as increasing the difficulty of repairing, and achieve the effects of simple and easy method, simple solution preparation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method for chemically plating nickel-phosphorus alloy on the surface of beryllium aluminum alloy of the present invention specifically comprises the following steps:

[0019] Step 1. Sand blasting: spray quartz sand onto the surface of beryllium aluminum alloy for surface cleaning and roughening treatment;

[0020] Step 2, cleaning the surface of the beryllium aluminum alloy with acetone and degreasing it;

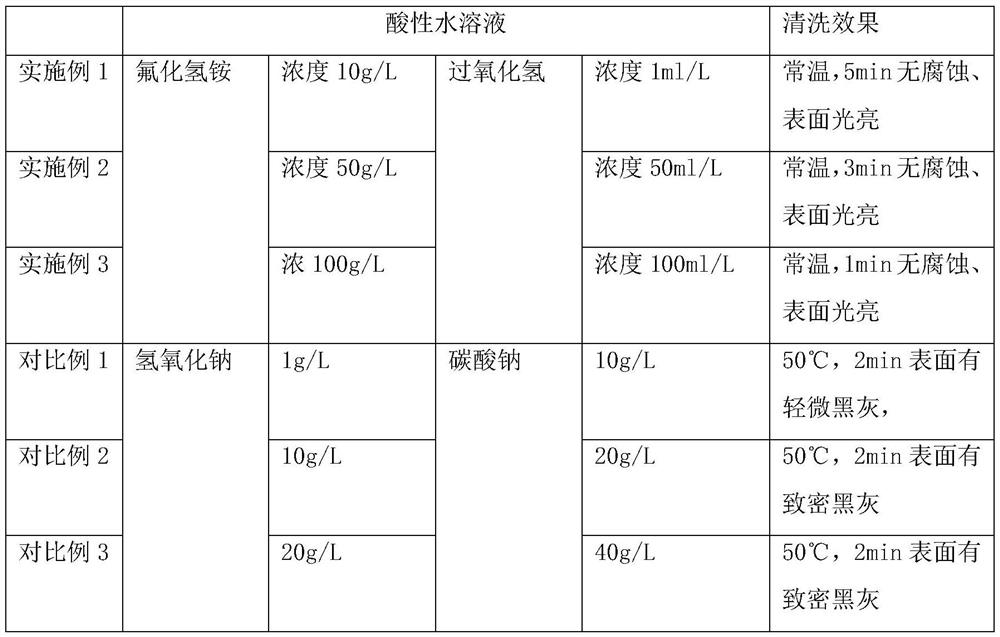

[0021] Step 3, Pickling: Use ammonium bifluoride and hydrogen peroxide acidic aqueous solution to clean the surface of the beryllium aluminum alloy treated in step 2; the concentration of ammonium bifluoride in the acidic aqueous solution is 10-100g / L, and the concentration of hydrogen peroxide is 1-100ml / L ;Clean at room temperature for 1-5min;

[0022] Step 4. Repeatedly wash with hot and cold water alternately for 3-5 times, using the principle of thermal expansion and contraction to thoroughly wash away the residual solution in the micropores on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com