Copper-based composite material reinforced by double-size hard particles and preparation method thereof

A copper-based composite material and hard particle technology, applied in the field of copper-based composite materials, can solve problems such as poor bonding between hard particles and copper interface, improve mechanical and friction and wear resistance, prevent adhesive wear, and stabilize friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

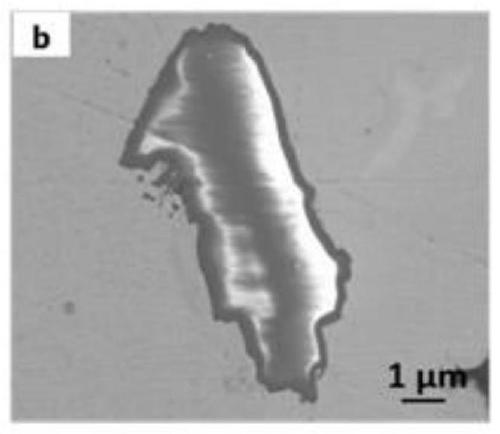

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a double-sized hard particle-reinforced copper-based composite material comprising the following steps:

[0047] (1) Mixing: Weigh small-sized hard particles, high-carbon ferrochrome particles, natural flake graphite and electrolytic copper powder as mixed raw material powders into a mixing tank according to the mass fraction, and add the mixing agent dropwise. Wherein, the weight ratio of the mixed raw material powder to the mixing agent is 1:0.002-0.005. Put the mixing tank into a three-dimensional swing mixer and mix for 3-4 hours; wherein, the rotation speed of the mixer is 350-450r / min; after the mixing is completed, a composite powder is obtained.

[0048] (2) Cold press forming: put the composite powder into a steel mold, and cold press form it under a hydraulic press. Wherein, the cold pressing pressure is 450-550 MPa, and the holding time is 30-60 s; the blank is obtained after cold pressing.

[0049] (...

Embodiment 1

[0051] (1) Take 3g copper-plated Si0 2 Granules (size 20μm), 8g high-carbon ferrochromium particles (size 100-300μm), 10g natural flake graphite (size 300μm), 79g electrolytic copper powder (size 35μm) into the mixing tank, drop 0.2ml of mixing agent , put the mixing tank into the three-dimensional oscillating mixer and mix the materials for 4 hours, wherein the rotation speed of the mixer is 400r / min to obtain the composite powder;

[0052] (2) Fill the composite powder with an inner diameter of In the steel mold, it is cold-formed under the hydraulic press. The cold pressing pressure is 500MPa, and the holding time is 1min. The blank is obtained after cold pressing.

[0053] (3) Put the cold-pressed billet into the inner diameter sintered in a vacuum hot-press furnace. The vacuum in the furnace is 10 -2 Pa, the heating rate in the furnace is 20°C / min, and the temperature is raised to 400°C for 2 hours, so that the mixing agent is completely volatilized from the bille...

Embodiment 2

[0055] (1) Take 1g copper-plated Si0 2 Granules (size 30μm), 6g high-carbon ferrochrome particles (size 100-300μm), 8g natural flake graphite (size 200μm), 85g electrolytic copper powder (size 35μm) are put into the mixing tank, and 0.2ml mixing agent is added dropwise , put the mixing tank into a three-dimensional oscillating mixer and mix for 3 hours, wherein the rotation speed of the mixer is 450r / min to obtain a composite powder.

[0056] (2) Fill the composite powder with an inner diameter of In the steel mold, it is cold-formed under the hydraulic press. Among them, the cold pressing pressure is 450 MPa, and the holding time is 1 min; the blank is obtained after cold pressing.

[0057] (3) Put the cold-pressed billet into the inner diameter sintered in a vacuum hot-press furnace. The vacuum in the furnace is 10 -2 Under Pa, the heating rate in the furnace is 25°C / min, and the temperature is raised to 450°C for 2 hours, so that the mixing agent is completely volati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com