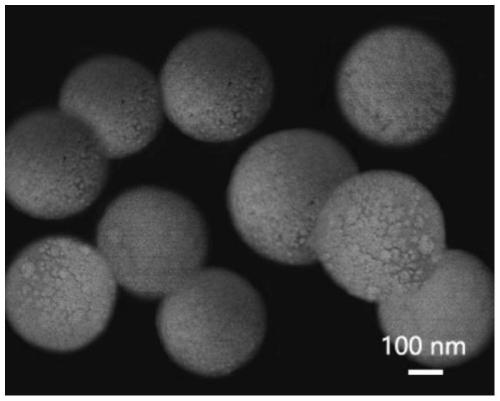

Nano zirconium carbide modified paraffin phase change microcapsules and preparation method thereof

A technology of nano-zirconium carbide and phase-change microcapsules, which can be used in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., and can solve the problems of poor thermal conductivity and poor light absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

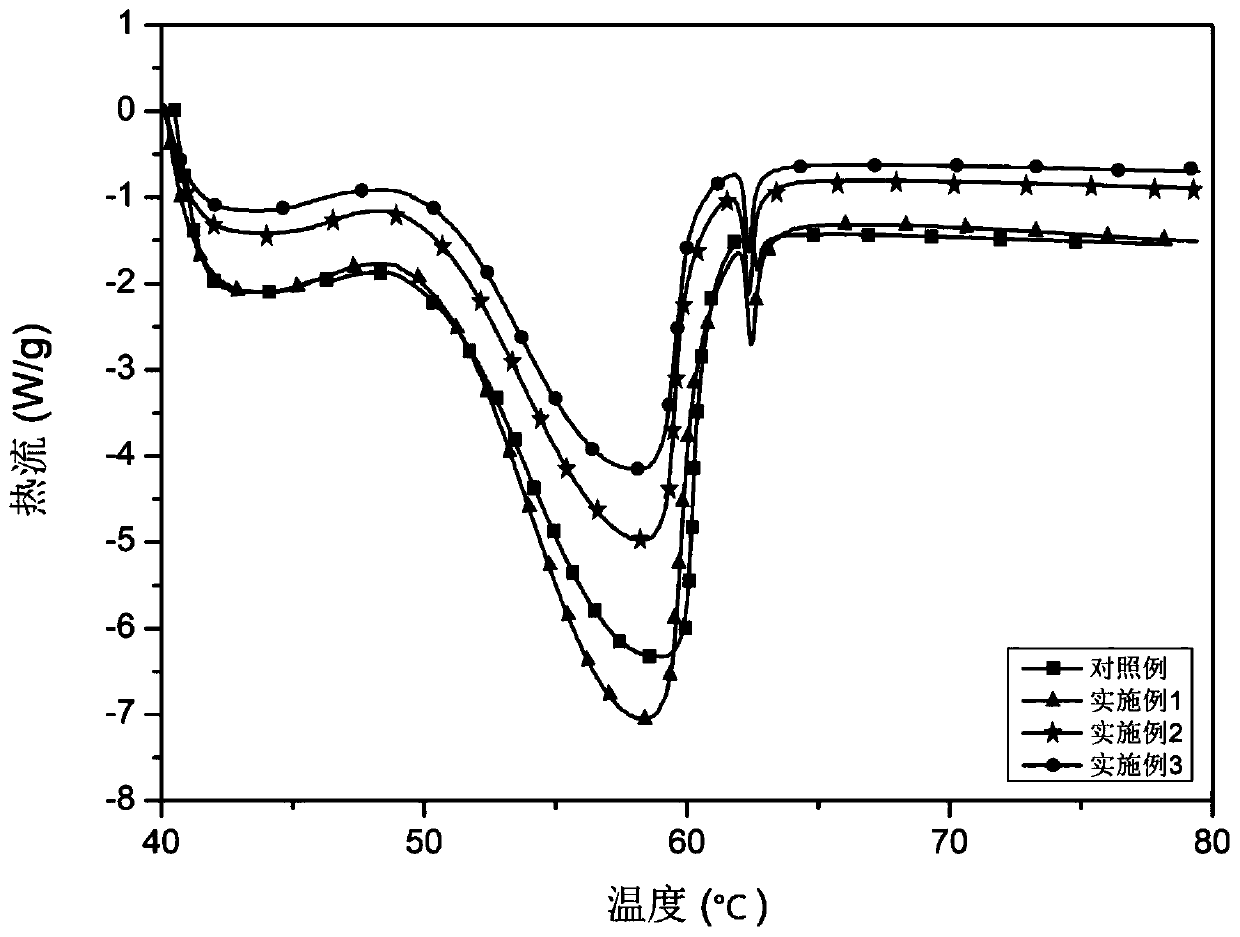

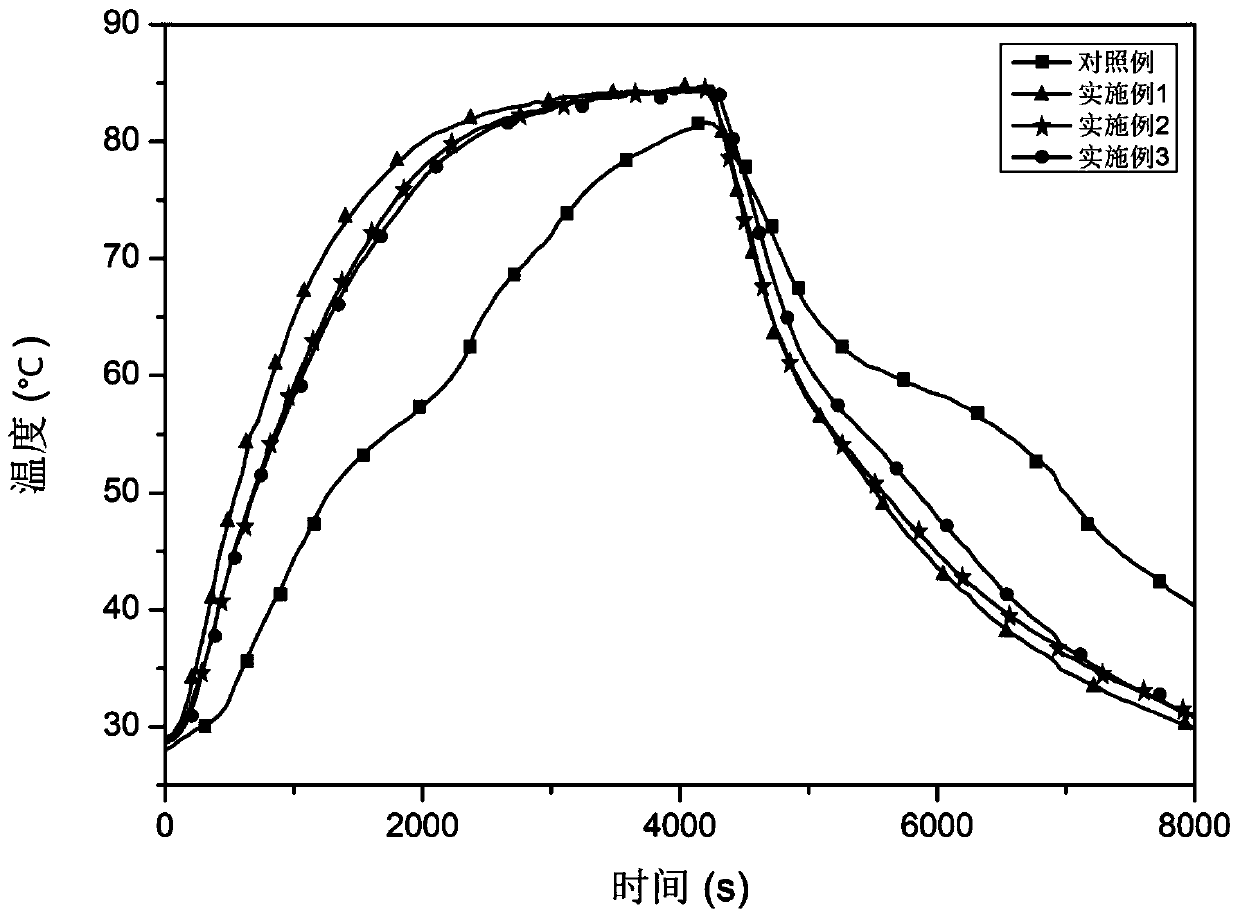

Embodiment 1

[0105] 1. Preparation of silane coupling agent solution

[0106] In a stirring state, the silane coupling agent KH550 is added to a concentration of 90wt% ethanol solution (concentration is usually 80-90wt%), stirring and mixing, the stirring speed is 300-400rpm; the stirring time is 30min (usually 20-40min ), until the solution is clear and transparent, the KH550 hydrolyzate (i.e. the silane coupling agent solution) is prepared for subsequent use, wherein the mass ratio of the silane coupling agent KH550 to the ethanol solution is 25:100 (usually (15-30):100) , that is, the mass concentration of the silane coupling agent solution is 20% (usually 15%-30%).

[0107] The silane coupling agent solution in the embodiment of the present invention is illustrated by taking the KH550 hydrolyzed solution with a concentration of 20% as an example, and other silane coupling agent solutions with a concentration of 15-30% are applicable to the present invention.

[0108] The silane coupli...

Embodiment 2

[0138] 1. Preparation of silane coupling agent solution

[0139] Same as Example 1.

[0140] 2. Hydrophobic treatment of nano zirconium carbide

[0141] Same as Example 1.

[0142] 3. Preparation of hydrophobically modified nano zirconium carbide dispersion

[0143] Except adding 0.6g hydrophobically modified nano-zirconium carbide powder to 20g deionized water to prepare a hydrophobically-modified nano-zirconium carbide-water dispersion (20.6g) with a concentration of 3wt%, the others were the same as in Example 1.

[0144] 4. Preparation of Nano Zirconium Carbide / Paraffin Pickering Emulsion

[0145] In addition to adding 20.6g hydrophobically modified nano-zirconium carbide-water dispersion to the paraffin-emulsifier mixed solution, a stable and uniform nano-zirconium carbide / paraffin Pickering emulsion (59.6g) was obtained, wherein the nano-zirconium carbide / paraffin Pickering emulsion modified Except that the mass ratio of zirconium carbide to paraffin is 3:100 (usuall...

Embodiment 3

[0151] 1. Preparation of silane coupling agent solution

[0152] Same as Example 1.

[0153] 2. Hydrophobic treatment of nano zirconium carbide

[0154] Same as Example 1

[0155] 3. Preparation of hydrophobically modified nano zirconium carbide dispersion

[0156] Except adding 0.4g hydrophobically modified nano-zirconium carbide powder to 20g deionized water to prepare a hydrophobically-modified nano-zirconium carbide-water dispersion (20.4g) with a concentration of 2wt%, all the others were the same as in Example 1.

[0157] 4. Preparation of Nano Zirconium Carbide / Paraffin Pickering Emulsion

[0158] In addition to adding 20.4g hydrophobically modified nano-zirconium carbide-water dispersion to the paraffin-emulsifier mixed solution, the hydrophobically modified nano-zirconium carbide in the hydrophobically modified nano-zirconium carbide-water dispersion and the paraffin wax in the paraffin-emulsifier mixed solution The mass ratio of the nanometer zirconium carbide / pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com