Vertically oriented carbon nanotube array and graphene composite film material and preparation method thereof

A carbon nanotube array and graphene composite technology, applied in the direction of carbon nanotubes, single-wall carbon nanotubes, multi-wall carbon nanotubes, etc., can solve the problems of limited application, large interlayer thermal resistance, etc., and achieve easy operation, Improved thermal conductivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

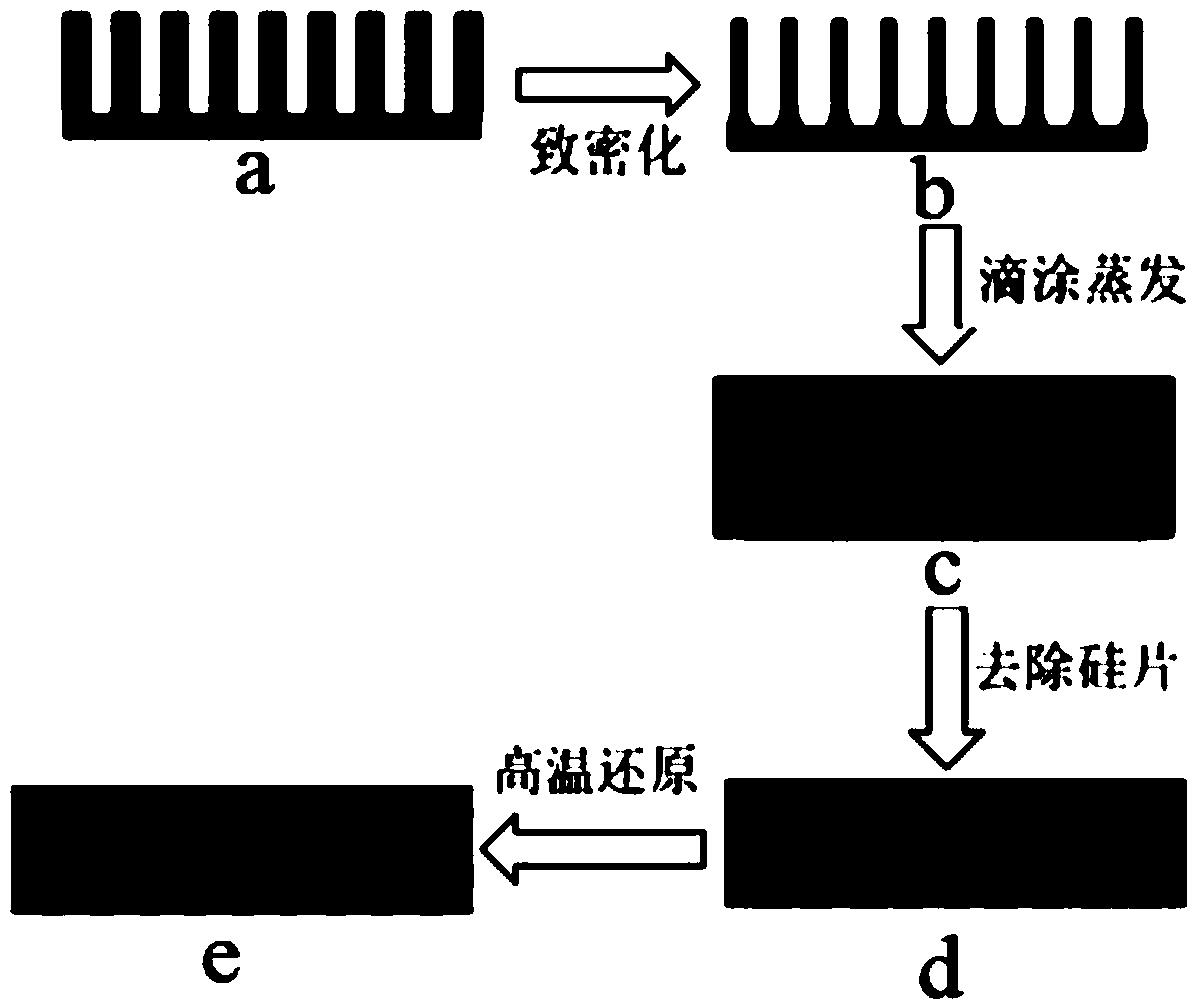

Method used

Image

Examples

Embodiment 1

[0042]In this embodiment, a vertically aligned carbon nanotube array and a graphene composite film material include graphene and a vertically aligned carbon nanotube array uniformly distributed therein; wherein the vertically aligned carbon nanotube array structure is a composite film material The body provides an additional longitudinal heat conduction path, forming a longitudinal heat conduction path between graphene layers; while graphene provides a transverse heat conduction path for the body of the composite film material; using vertically oriented carbon nanotube arrays and oriented heat conduction channels of graphene materials, the vertical Oriented carbon nanotube arrays and graphene materials form a three-dimensional network heat conduction channel structure, the longitudinal and lateral heat conduction of the composite film are complementary, and the contact positions or connections between vertically oriented carbon nanotube arrays and graphene form a thermal interfa...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, especially in that:

[0058] In this embodiment, a vertically aligned carbon nanotube array and a graphene composite film material include graphene and a vertically aligned carbon nanotube array uniformly distributed therein; wherein the vertically aligned carbon nanotube array structure is a composite film material The body provides an additional longitudinal heat conduction path, forming a longitudinal heat conduction path between graphene layers; while graphene provides a transverse heat conduction path for the body of the composite film material; using vertically oriented carbon nanotube arrays and oriented heat conduction channels of graphene materials, the vertical Oriented carbon nanotube arrays and graphene materials form a three-dimensional network heat conduction channel structure, the longitudinal and lateral heat conduction of the composite film are complementary, and the contact positions or connections ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com