Wear-resistant and crease-resistant fabric

A fabric and base fabric layer technology, applied in the field of textile fabrics, can solve the problems of low tensile strength, insufficient adhesion, and short service life of waterproof fabrics, and achieve the effects of excellent air permeability, extended service life, and good tear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail in conjunction with the embodiments, but the implementation of the present invention is not limited thereto.

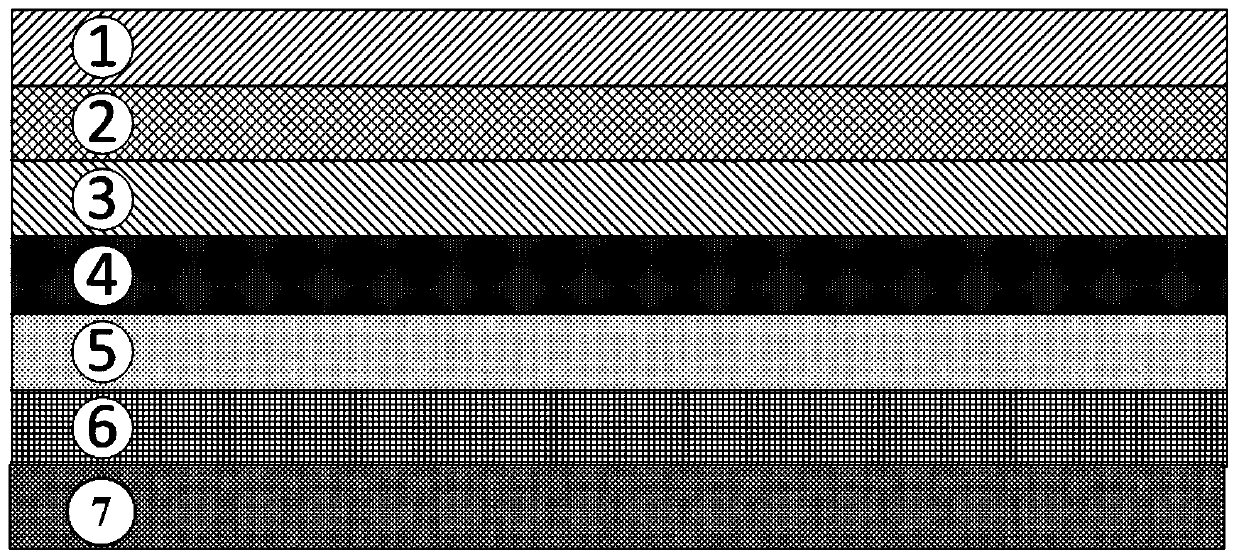

[0019] like figure 1 As shown, the wear-resistant and wrinkle-resistant fabric provided by the present invention includes an inner lining layer 1, a base fabric layer 2, a thermal insulation layer 3, an anti-wrinkle layer 4, a non-woven fabric layer 5, a TPU film layer 6, and a nylon mesh that are sequentially stacked from inside to outside. Grid level 7. According to the actual application of the fabric, in order to improve the anti-ultraviolet function of the fabric, the nylon mesh layer 7 can be coated with an anti-ultraviolet coating; Teflon coating with water barrier function.

[0020] The inner lining layer 1 is connected to the TPU film layer 6 by bonding, and the nylon grid layer is hot-compressed on the surface of the TPU film layer.

[0021] In this embodiment, the total thickness of the wear-resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com