Method of producing alloy plate hammer based on quenching and liquid die forging

A technology of liquid die forging and production method, applied in the furnace type, furnace, heat treatment furnace and other directions, can solve the problem of difficult to meet the requirements of wear-resistant castings, achieve good economic and social benefits, reduce production costs, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

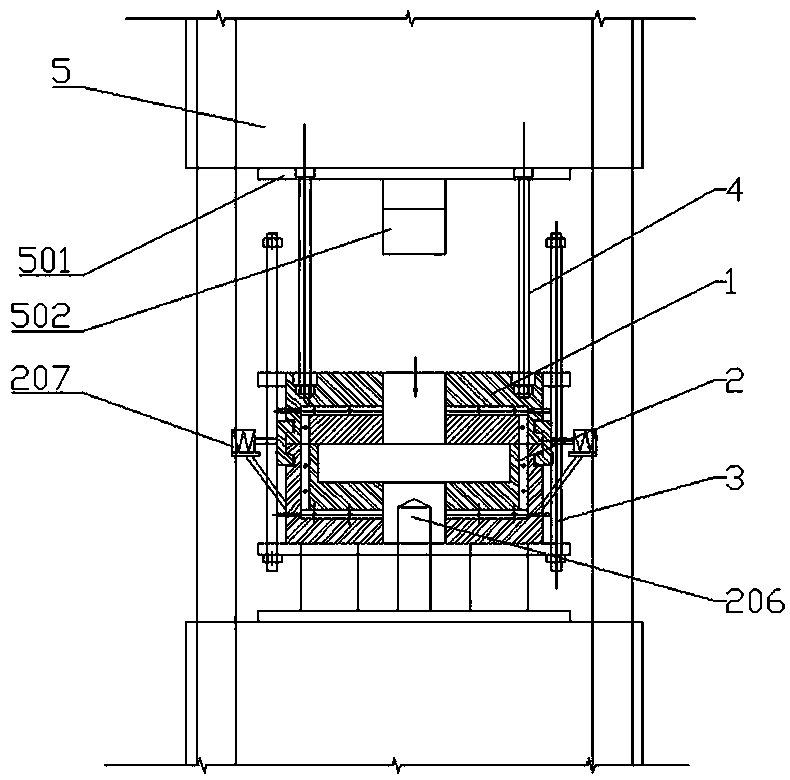

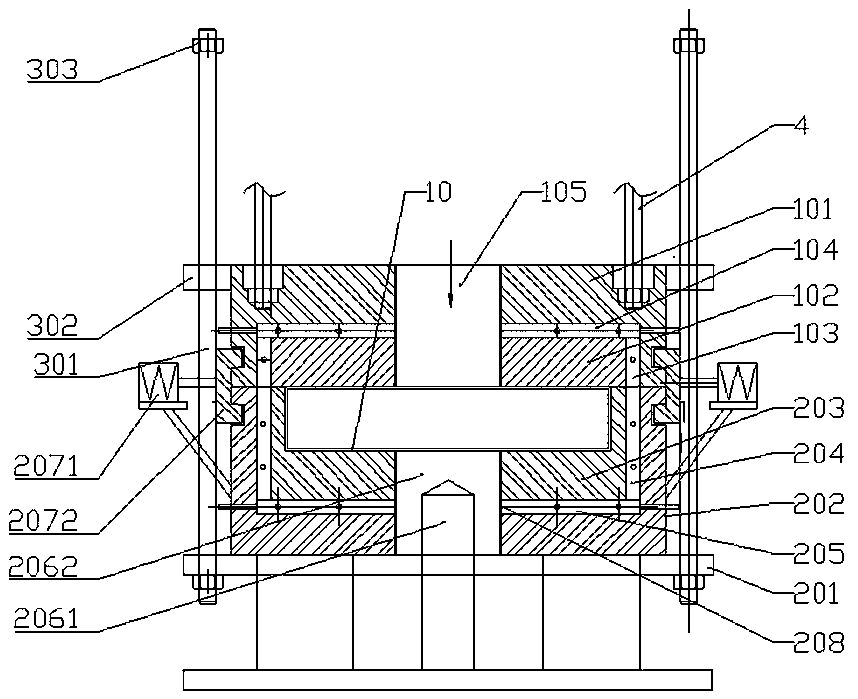

[0036] The best embodiment: the alloy blow bar production method based on chilling and liquid die forging, which is characterized in that it is realized on a liquid die forging machine based on a special alloy blow bar mold;

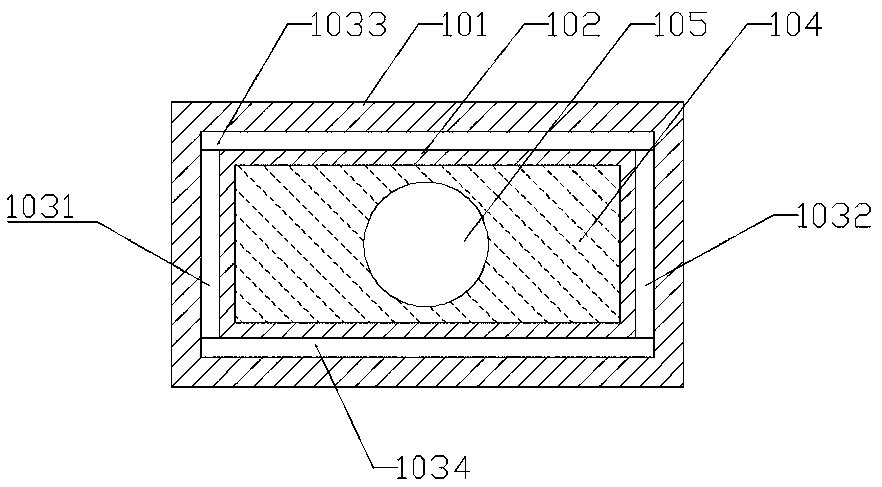

[0037] The structure of the special alloy blow bar die: as figure 1 and figure 2As shown, the water-cooled alloy blow bar liquid forging die includes an upper die 1 and a lower die 2, the upper die is connected to the lower die through a guide assembly 3, the upper die 1 includes an upper die sleeve 101, an upper die core 102, an upper excitation Cooling part 103, water-cooled upper chilling plate 104, the upper die cover is connected with the slider 501 on the liquid die forging machine 5 through the tie rod 4, the upper cooling part is fixed between the upper die cover and the side of the upper die core, and the water cooling The upper quenching plate of the type is fixed between the upper die sleeve and the top surface of the upper die core, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com