Method and equipment for preparing heavy metal ion adsorbent by using fullerene

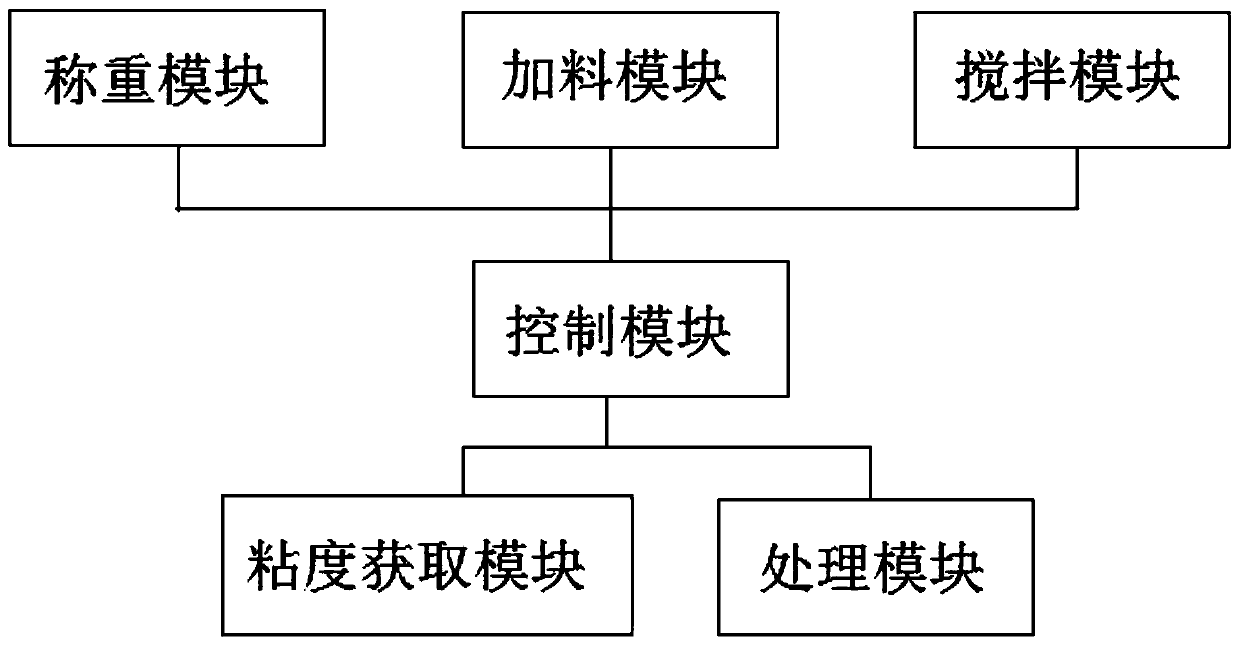

A technology of heavy metal ions and adsorbents, applied in the field of machinery, can solve the problems of insufficient automation, intelligence, inaccurate reaction control, and affecting the performance of adsorbents, etc., and achieve the effects of reducing human factors, comprehensive test methods, and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

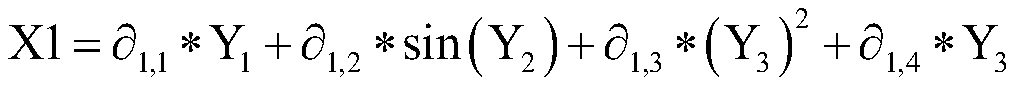

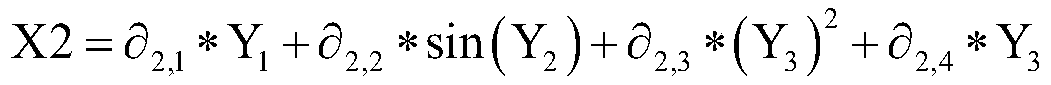

Method used

Image

Examples

Embodiment 1-3

[0119] Below is the detailed embodiment 1-3 of the method for utilizing above-mentioned equipment to prepare heavy metal ion adsorbent, and adsorption experiment is as follows:

Embodiment 1

[0121] S1. Weigh 100g of deionized water and add it to the first reaction kettle, then weigh 10g of fullerene, 20g of carboxymethyl cellulose, and 2g of β-cyclodextrin in turn, add it to 100g of deionized water, and stir for 1h. get the mixture;

[0122] S2. Add 50 g of 40% sodium hydroxide solution to the mixed solution described in S1 and continue to stir for 20 minutes to obtain a solution;

[0123] S3. Add 11 mL of epichlorohydrin dropwise into the solution described in S2, and continue stirring for 8 hours to obtain a reaction product;

[0124] S4. The reaction product was filtered and dried, then soaked in ethanol solution with a concentration of 15 g / L pyromellitic acid for 10 min, filtered, and freeze-dried at -20° C. for 24 h to obtain a heavy metal adsorbent.

Embodiment 2

[0126] S1. Weigh 100g of deionized water, add it to the first reaction kettle, then weigh 10g of fullerene, 20g of carboxymethyl cellulose, and 3g of β-cyclodextrin in turn, add it to 100g of deionized water, and stir for 1.2h , to get a mixture;

[0127] S2. Add 55 g of sodium hydroxide solution (40%) to the mixed solution described in S1, and continue stirring for 25 min to obtain a solution;

[0128] S3. Add 12.2 mL of epichlorohydrin dropwise into the solution described in S2, and continue stirring for 9 hours to obtain a reaction product;

[0129] S4. Filter and dry the reaction product, then soak it in ethanol solution with a concentration of 18g / L pyromellitic acid for 12min, filter, and freeze-dry at -20°C for 24h to obtain the heavy metal adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com