Composite copper layer polyvinyl chloride leakage waveguide feeder line and manufacturing method thereof

A polyvinyl chloride and leakage technology, which is applied to waveguides, waveguide-type devices, circuits, etc., can solve the problems of uneven longitudinal distribution of radiation field waveguides, and achieve the effects of light weight, convenient installation and laying, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

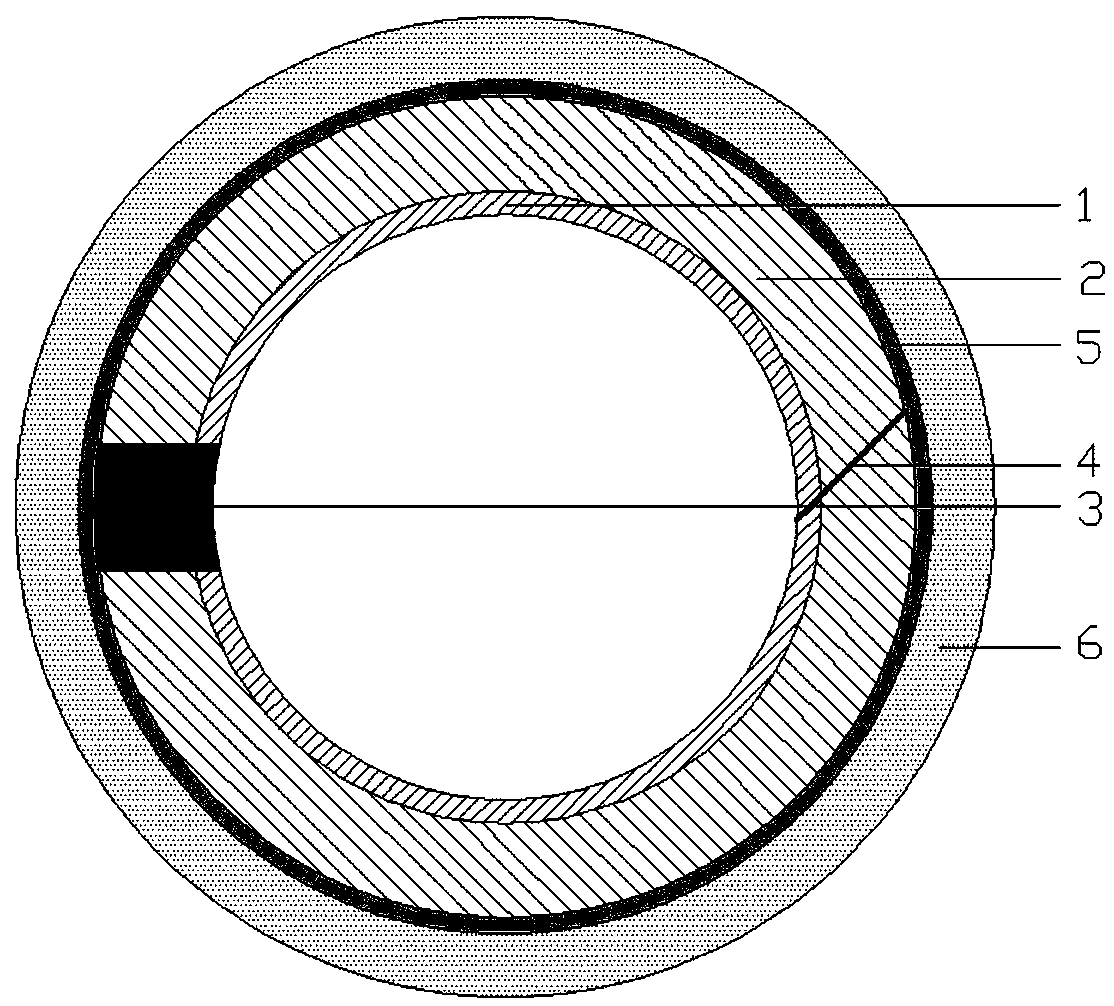

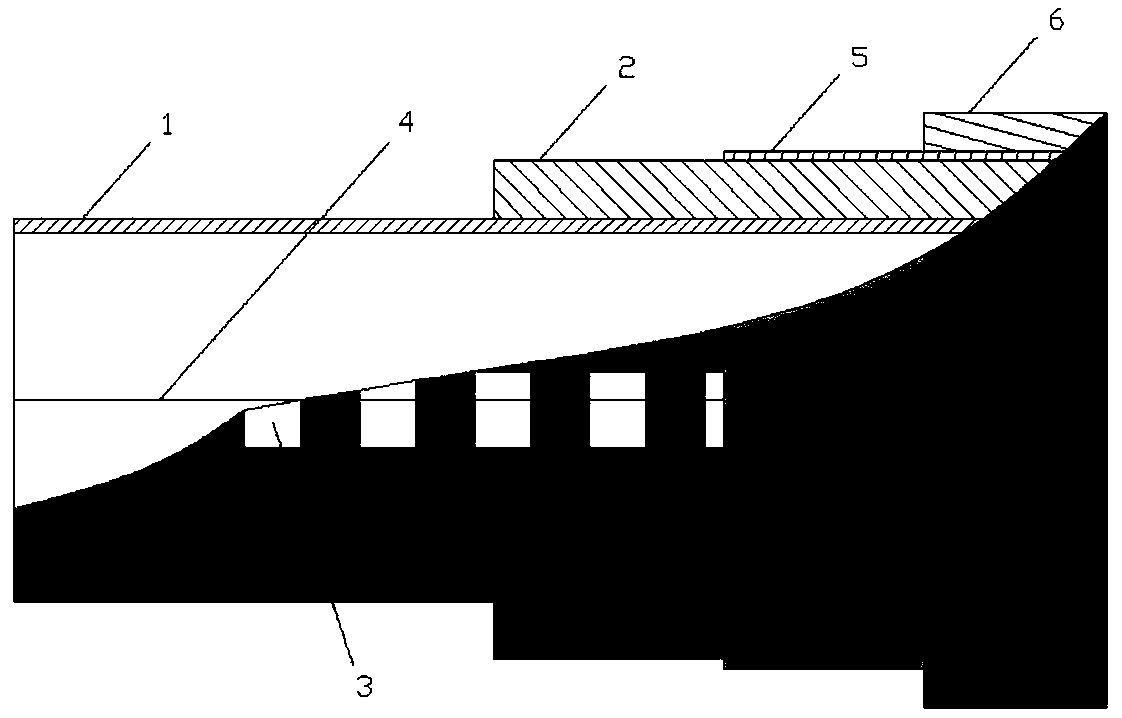

[0032] Composite copper layer polyvinyl chloride leaky waveguide feeder, its structure radially distributed from inside to outside is as follows: copper foil layer 1, polyvinyl chloride hard round tube 2 and flame-retardant protective layer 6, the polyvinyl chloride hard round tube The outer surface of the pipe 2 is also provided with a number of slots 3 along the length direction, and the opposite surface of the slots 3 is the joint 4 of the ridge structure.

[0033] Further, a polyester film layer 5 is provided between the polyvinyl chloride rigid round pipe 2 and the flame-retardant protection layer 6 .

[0034] Further, the copper foil layer 1 is a copper-plastic composite film, and the copper-plastic composite film has a double-layer structure, with a copper layer inside and a plastic layer outside. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com