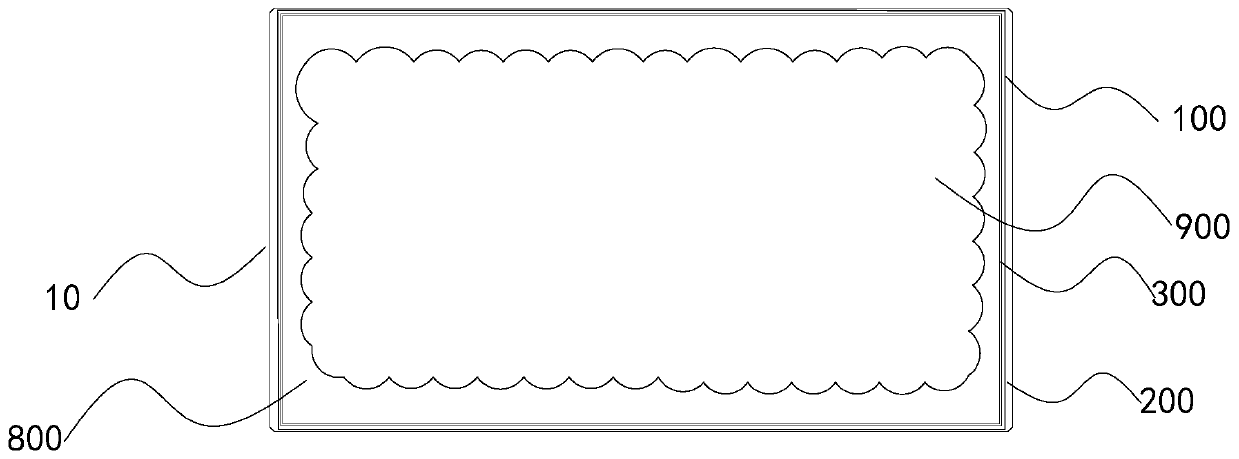

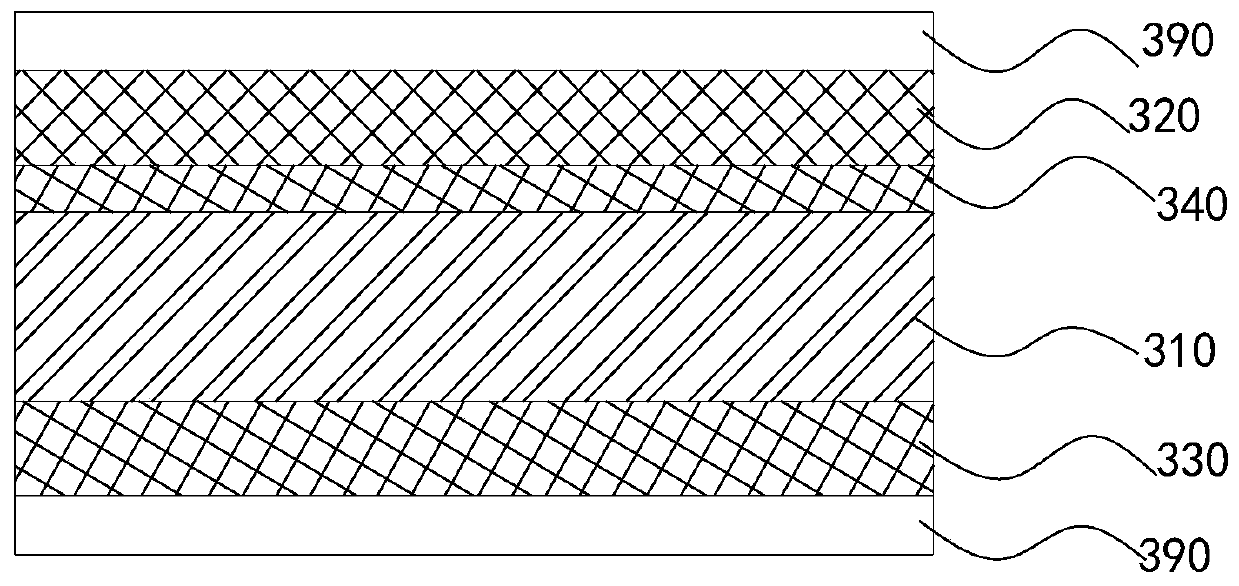

Display assembly, display equipment and assembly method of display assembly

A technology of display components and assembly methods, applied in optical components, digital data processing parts, optics, etc., can solve problems such as poor sealing effect, broken screen, increase production cost, etc., to improve display effect, reduce relative displacement, The effect of reducing the chance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0154] In the first embodiment, the method specifically includes the following steps:

[0155] placing the display panel on the first platform;

[0156] bonding the first adhesive layer of the adhesive member to the transparent protective layer, and placing the transparent protective layer on the display panel;

[0157] Under the action of its own gravity or external force, the transparent protective layer at least partially sags its central region toward the display panel side, and at least partially evacuates the air between the transparent protective layer and the display panel;

[0158] bonding the second adhesive layer of the adhesive to the display panel, and forming a sealing structure between the edge side of the display panel and the transparent protective layer, and the display panel and the transparent protective layer are adsorbed to form a bonding area and a gap area; the gap area surrounds the bonding area, and the adhesive piece surrounds the gap area. In the ...

no. 2 example

[0159] In the second embodiment, the method specifically includes the following steps:

[0160] placing the display panel on the first platform;

[0161] bonding the second adhesive layer of the adhesive member to the display panel, and placing the transparent protective layer on the display panel;

[0162] Under the action of its own gravity or external force, the transparent protective layer at least partially sags its central region toward the display panel side, and at least partially evacuates the air between the transparent protective layer and the display panel;

[0163] bonding the first adhesive layer of the adhesive member to the transparent protective layer to form a sealing structure between the edge side of the display panel and the transparent protective layer, the display panel and the transparent protective layer are adsorbed to form a bonding area and a gap area; the gap area surrounds the bonding area, and the adhesive piece surrounds the gap area.

[0164]...

no. 3 example

[0165] In the third embodiment, the method specifically includes the following steps:

[0166] placing the transparent protective layer on the first platform;

[0167] bonding the first adhesive layer of the adhesive member to the transparent protective layer, and placing the display panel on the transparent protective layer;

[0168] Under the action of its own gravity or external force, the central region of the display panel is at least partially sunken toward the side of the transparent protective layer, and the air between the transparent protective layer and the display panel is at least partially evacuated;

[0169] The second adhesive layer of the adhesive is bonded to the display panel to form a sealing structure between the edge side of the display panel and the transparent protective layer, and the display panel and the transparent protective layer are adsorbed to form a bonding area and A gap area; the gap area surrounds the bonding area, and the adhesive piece su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com