Production process and processing production line for wood vinegar compound preparation

A composite preparation and production technology technology, applied in the field of wood vinegar composite preparations, can solve the problems of unstable use effect, large difference in components, difficult popularization and application, etc., and achieve the effects of stable effect and efficient production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The production process of the wood vinegar compound preparation of this application includes the following steps:

[0050] a. Making crude wood vinegar;

[0051] Use anaerobic carbonization process to make crude wood vinegar from crop stalks;

[0052] b. Obtain effective wood vinegar;

[0053] Pour the carbonized crude wood vinegar into a container, and use the method of static separation to gradually precipitate the suspended impurities and heavy oil in the crude wood vinegar. At the same time, the unstable components in the crude wood vinegar are oxidized and polymerized. It also gradually precipitates. Finally, the wood vinegar in the container is divided into 3 layers, the upper layer is unstable wood vinegar, the middle clear part is effective wood vinegar, and the lower layer is high boiling point and hard to volatile heavy wood vinegar;

[0054] c. Obtain refined wood vinegar;

[0055] Use vacuum distillation to distill the effective wood vinegar to obtain refined wood vin...

Embodiment 2

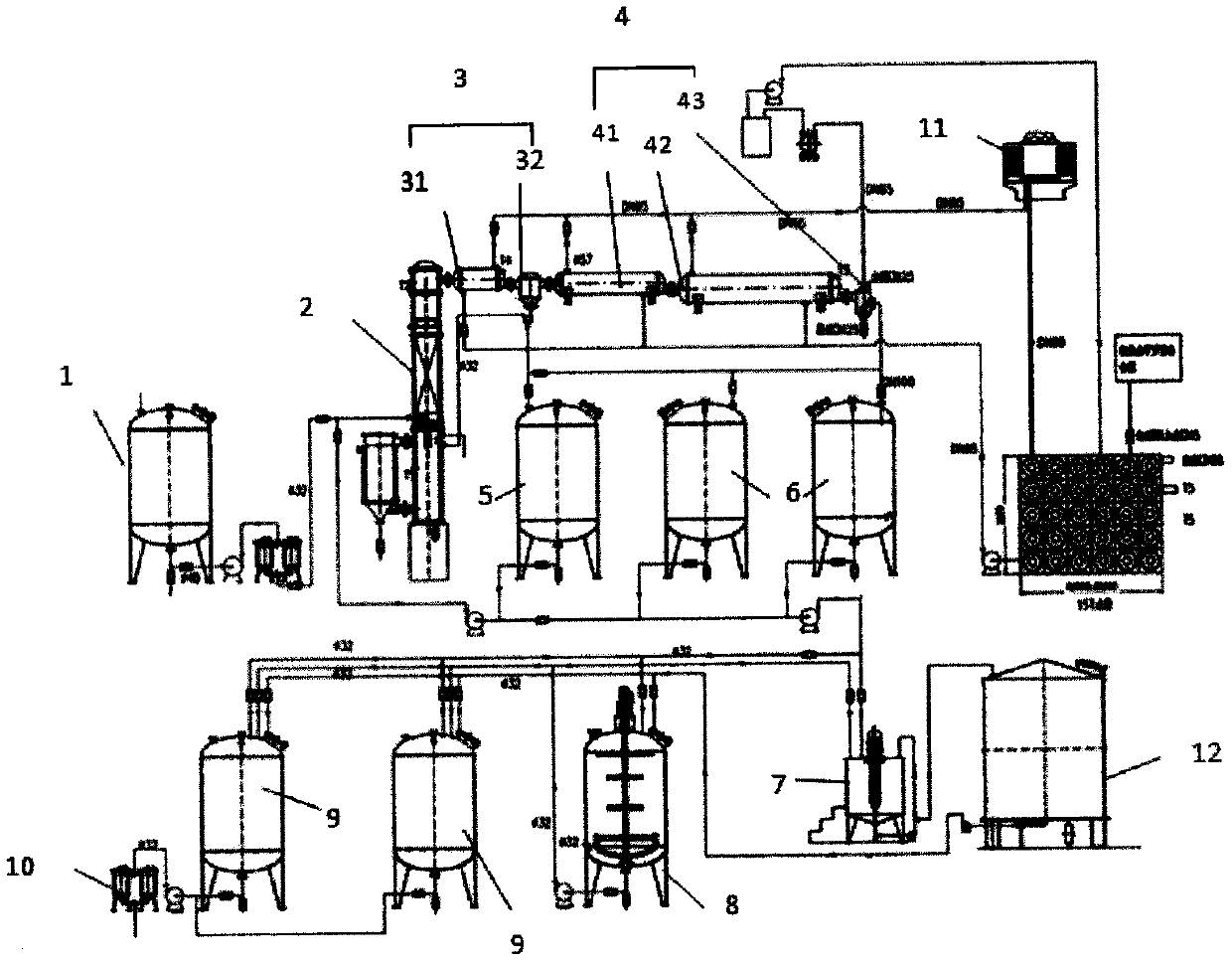

[0066] figure 1 It is a structural schematic diagram of the processing production line of the wood vinegar compound preparation provided by the present invention, such as figure 1 As shown, the processing production line of wood vinegar compound preparation provided by the present invention includes:

[0067] The raw material buffer tank 1 is used to store the effective wood vinegar liquid;

[0068] Distillation tower 2, distillation tower 2 is connected with raw material buffer tank 1, and is used to distill the effective wood vinegar liquid, so that the effective wood vinegar liquid is separated from the gas and liquid in the distillation tower 2, and the purity of the material liquid is improved during the continuous evaporation and cooling process. , And produce high temperature gas;

[0069] The first-stage condensation separation device 3, the first-stage condensation separation device 3 is connected to the distillation tower 2, the high-temperature gas enters the first-stage...

Embodiment 3

[0078] The processing production line of the wood vinegar compound preparation provided in the third example is a further improvement of the processing production line of the wood vinegar compound preparation provided in the second embodiment. figure 1 On the basis of, the first-stage condensation separation device 3 includes a first condenser 31 and a first steam-water separator 32 connected;

[0079] The first condenser 31 is connected with the distillation column 2, the first steam-water separator 32 is connected with the secondary condensation separation device 4, and the first intermediate storage tank 5 is connected with the first steam-water separator 32.

[0080] Specifically, the secondary condensation separation device 4 includes a second condenser 41, a third condenser 42, and a second steam-water separator 43 connected to each other. The second condenser 41 is connected to the first steam-water separator 32, and the second intermediate The storage tank 6 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com