Coating capable of decomposing formaldehyde and releasing negative ions

A technology of formaldehyde release and negative ions, which is applied in the field of coatings, can solve the problems of no coating, etc., and achieve the effect of obvious net increase, wide adaptability and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

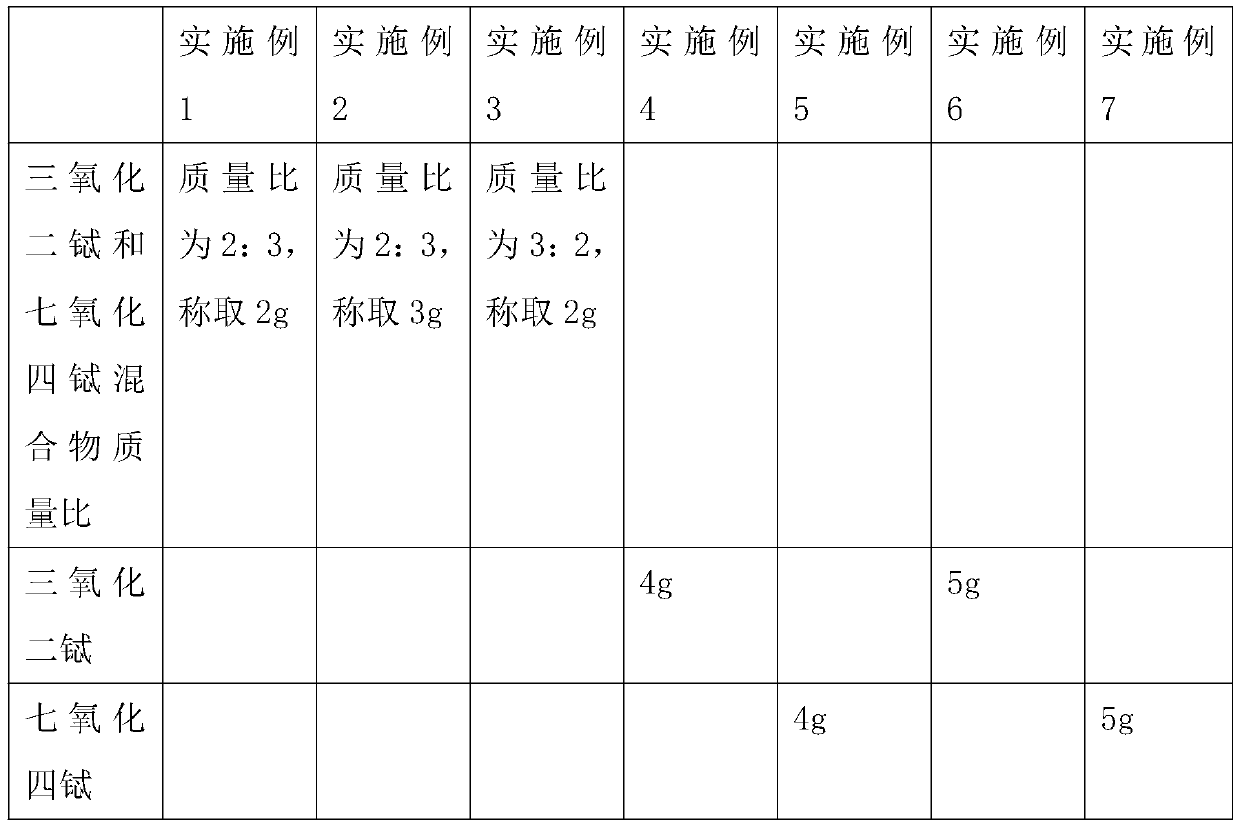

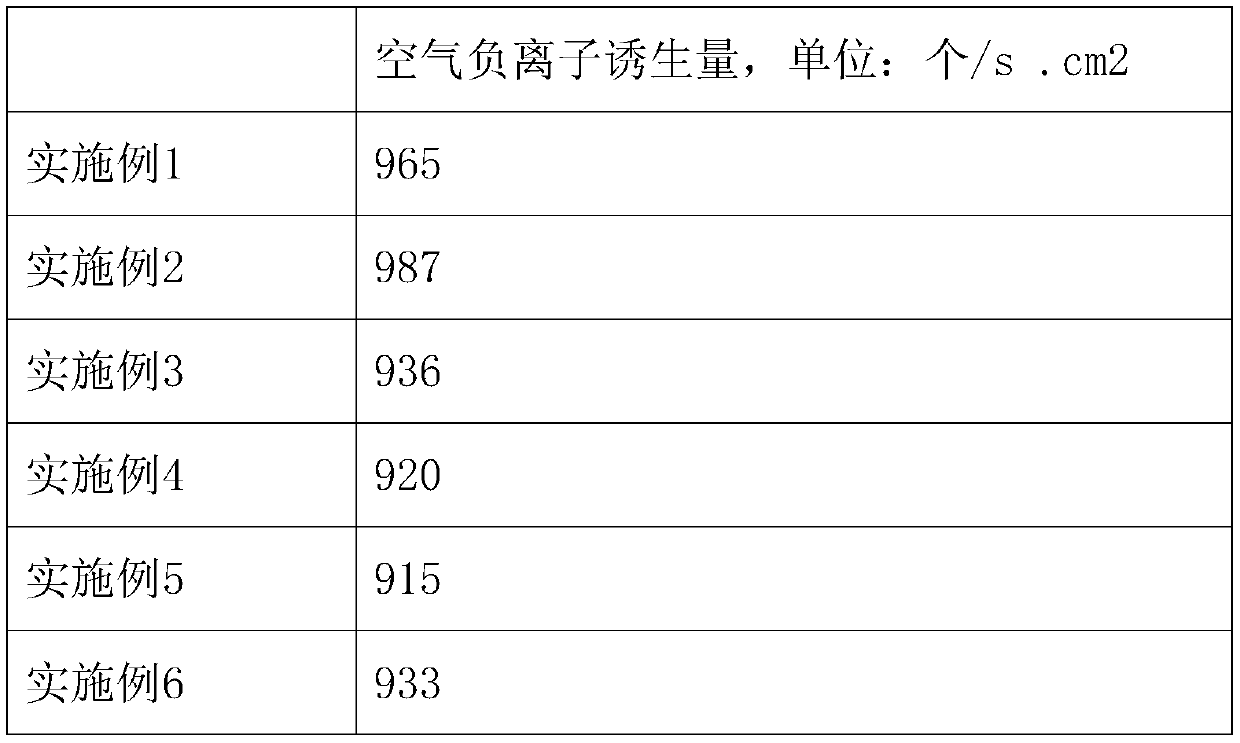

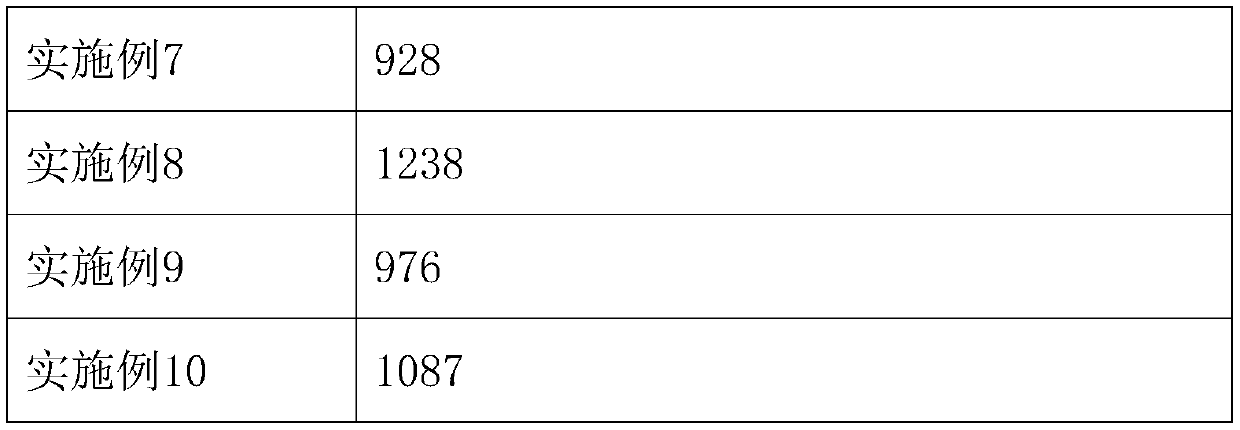

[0022] Embodiment 1-3: Weigh each raw material according to the corresponding data in Table 1, mix the mixture of diterbium trioxide and tetraterbium heptoxide, tourmaline and opal evenly, pulverize and grind, and control the particle size D50≤0.5 micron to obtain the The above-mentioned negative ion additives. Then the negative ion additive is added into the base material by 1% by weight.

Embodiment 4-7

[0023] Embodiment 4-7: Weigh each raw material according to the corresponding data in Table 1, mix diterbium trioxide, tetraterbium heptoxide tourmaline and opal evenly, pulverize, grind, control the particle size D50≤0.5 micron, and the negative ion can be obtained additive. Then the negative ion additive is added into the base material by 1% by weight.

[0024] Base material ratio:

[0025] 40 parts of water; 3 parts of potassium methyl siliconate; 1 part of 5040 dispersant; 0.3 parts of wetting agent ethylene glycol; 10 parts of titanium dioxide; 20 parts of hydroxyethyl cellulose 3000; 20 parts of SF-109 emulsion; 11 parts of glue powder; 12 parts of gelatin powder.

Embodiment 8

[0026] Embodiment 8: adopt the method for embodiment 1, add titanium dioxide in formula and be Fe3+doped nanometer titanium dioxide, Pt 4+ A mixture of ion-doped nano-titanium dioxide and N-doped nano-titanium dioxide, Fe3+ doped nano-titanium dioxide, Pt 4+ The mixing ratio of ion-doped nano-titanium dioxide and N-doped nano-titanium dioxide is 4:2:4; Fe3+ doped nano-titanium dioxide, Pt 4+ The mixture of ion-doped nano-titanium dioxide and N-doped nano-titanium dioxide is added to the base material of the coating according to the ratio of 1% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com