Novel high-temperature alcohol reforming fuel cell system

A fuel cell system, high temperature technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of heat loss, increased vehicle weight, frequent refueling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

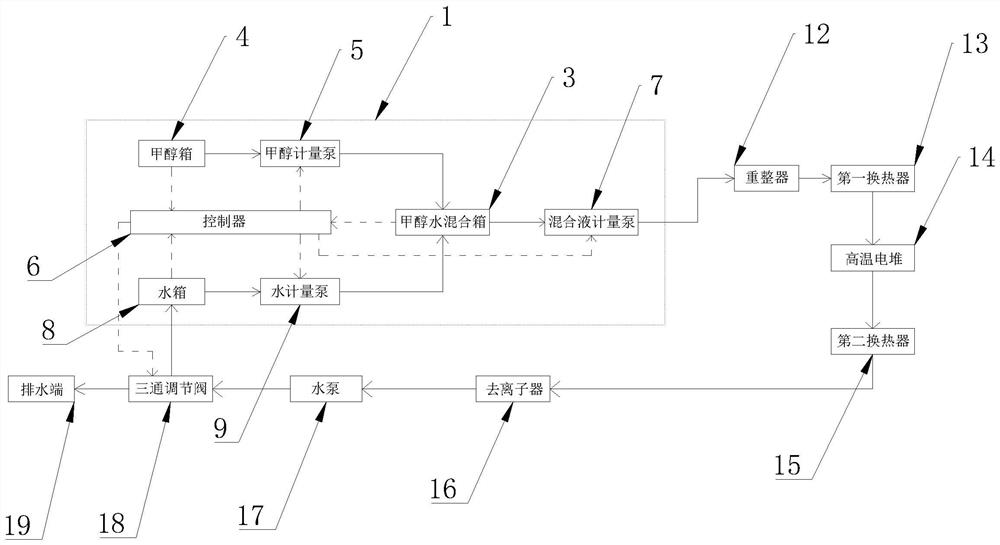

[0014] The present invention will be further described below in conjunction with the drawings.

[0015] Such as figure 1 As shown, a novel high-temperature alcohol reforming fuel cell system includes a fuel preparation system module 1, a reformer 12, and a high-temperature stack 14. The fuel preparation system module 2 includes a controller 6, a methanol-water mixing tank 3, A methanol supply unit and a water supply unit are connected to the methanol-water mixing tank 3, the methanol supply unit includes a methanol tank 4 and a methanol metering pump 5 connected in sequence, and the water supply unit includes a water tank 8 and a water metering pump 9 connected in sequence, The methanol-water mixing tank 3 is connected to a mixed liquid metering pump 7. The methanol-water mixing tank 3, the methanol tank 4, and the water tank 8 can send liquid level signals to the controller 6, and the controller 6 can send driving signals to methanol metering. Pump 5, water metering pump 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com