Methods of producing terbium oxide and dysprosium oxide

A technology of dysprosium oxide and terbium oxide, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of high impurity content of ytterbium oxide and cannot be removed, and achieve high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

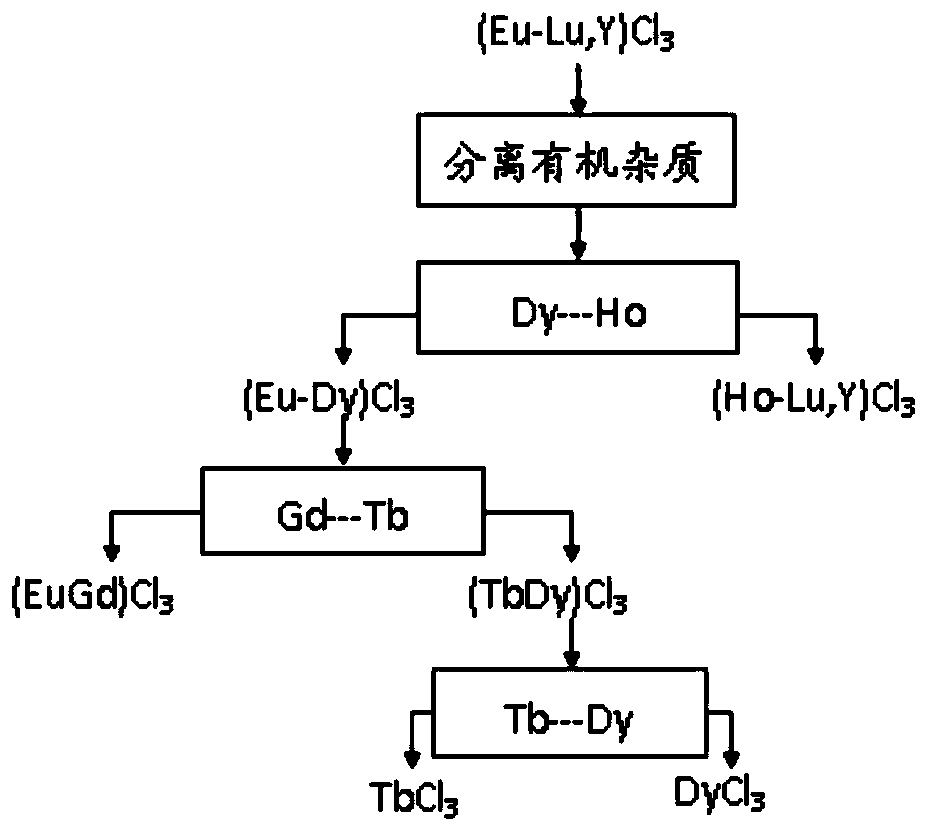

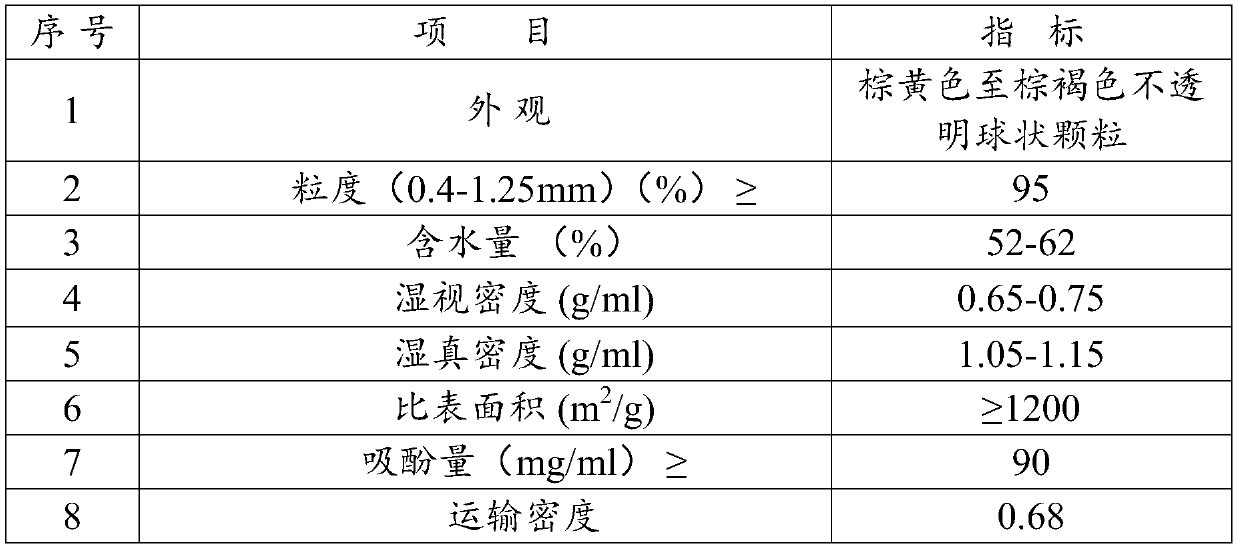

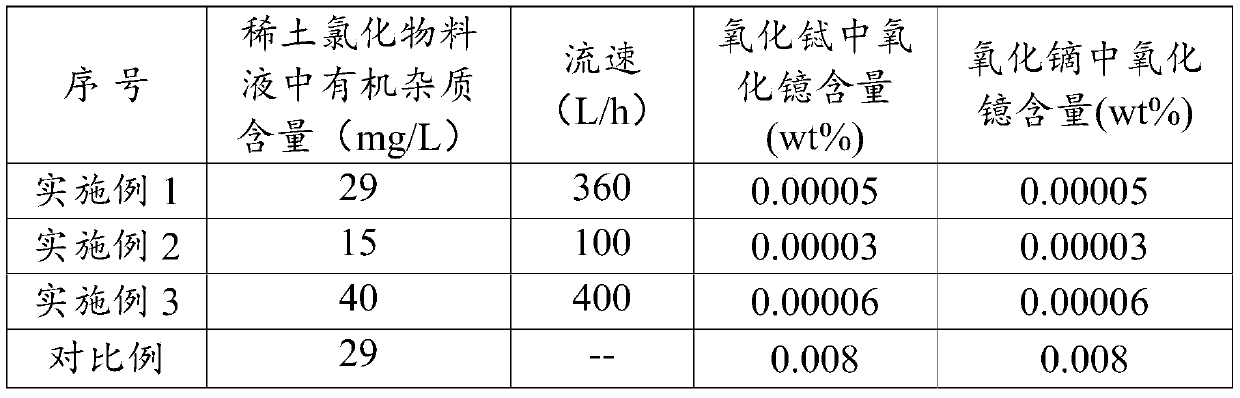

[0049] The rare earth chloride feed liquid (rare earth chloride concentration is 1.5mol / L, hydrogen ion concentration is 0.3mol / L, and organic impurity concentration is 29mg / L) containing terbium and dysprosium element that samarium europium extraction separates obtains with 360L / h The flow rate is passed through the resin column (0.3m in diameter and 3m in height) filled with cross-linked styrene-divinylbenzene polymer; the rare earth chloride feed solution passing through the resin column is adjusted to 0.2mol hydrogen ion concentration with ammonium bicarbonate / L to obtain the treated rare earth chloride feed liquid.

[0050] The treated rare earth chloride feed liquid is used as the separation feed liquid, the extractant is 2-ethylhexyl phosphate mono-2-ethylhexyl ester, and the diluent is kerosene, and dysprosium-holmium extraction, gadolinium-terbium extraction and terbium-dysprosium extraction are carried out to obtain Terbium chloride solution and Dysprosium chloride ...

Embodiment 2

[0053] The rare earth chloride feed liquid (the concentration of rare earth chloride is 1.5mol / L, the concentration of hydrogen ion is 0.4mol / L, and the concentration of organic impurities is 15mg / L) containing terbium and dysprosium elements obtained by extracting and separating samarium and europium is 100L / h The flow rate is passed through the resin column (0.3m in diameter and 3m in height) filled with cross-linked styrene-divinylbenzene polymer; the rare earth chloride feed solution passing through the resin column is adjusted to 0.2mol hydrogen ion concentration with ammonium bicarbonate / L to obtain the treated rare earth chloride feed liquid.

[0054] The treated rare earth chloride feed liquid is used as the separation feed liquid, the extractant is 2-ethylhexyl phosphate mono-2-ethylhexyl ester, and the diluent is kerosene, and dysprosium-holmium extraction, gadolinium-terbium extraction and terbium-dysprosium extraction are carried out to obtain Terbium chloride sol...

Embodiment 3

[0057] The rare earth chloride feed liquid (the concentration of rare earth chloride is 1.5mol / L, the concentration of hydrogen ion is 0.5mol / L, and the concentration of organic impurities is 40mg / L) containing terbium and dysprosium elements obtained by extracting and separating samarium and europium is 400L / h The flow rate is passed through the resin column (0.3m in diameter and 3m in height) filled with cross-linked styrene-divinylbenzene polymer; the rare earth chloride feed solution passing through the resin column is adjusted to 0.2mol hydrogen ion concentration with ammonium bicarbonate / L to obtain the treated rare earth chloride feed liquid.

[0058] The treated rare earth chloride feed liquid is used as the separation feed liquid, the extractant is 2-ethylhexyl phosphate mono-2-ethylhexyl ester, and the diluent is kerosene, and dysprosium-holmium extraction, gadolinium-terbium extraction and terbium-dysprosium extraction are carried out to obtain Terbium chloride sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com