Light-and-thin-kind waste steel recycling method

A thin, scrap steel technology, applied in cleaning methods and utensils, chemical instruments and methods, furnace types, etc., can solve problems such as affecting the safe steelmaking of steelmaking converters, low scrap yield, and affecting steelmaking quality and steelmaking efficiency. , to achieve the effect of improving recycling rate and increasing recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

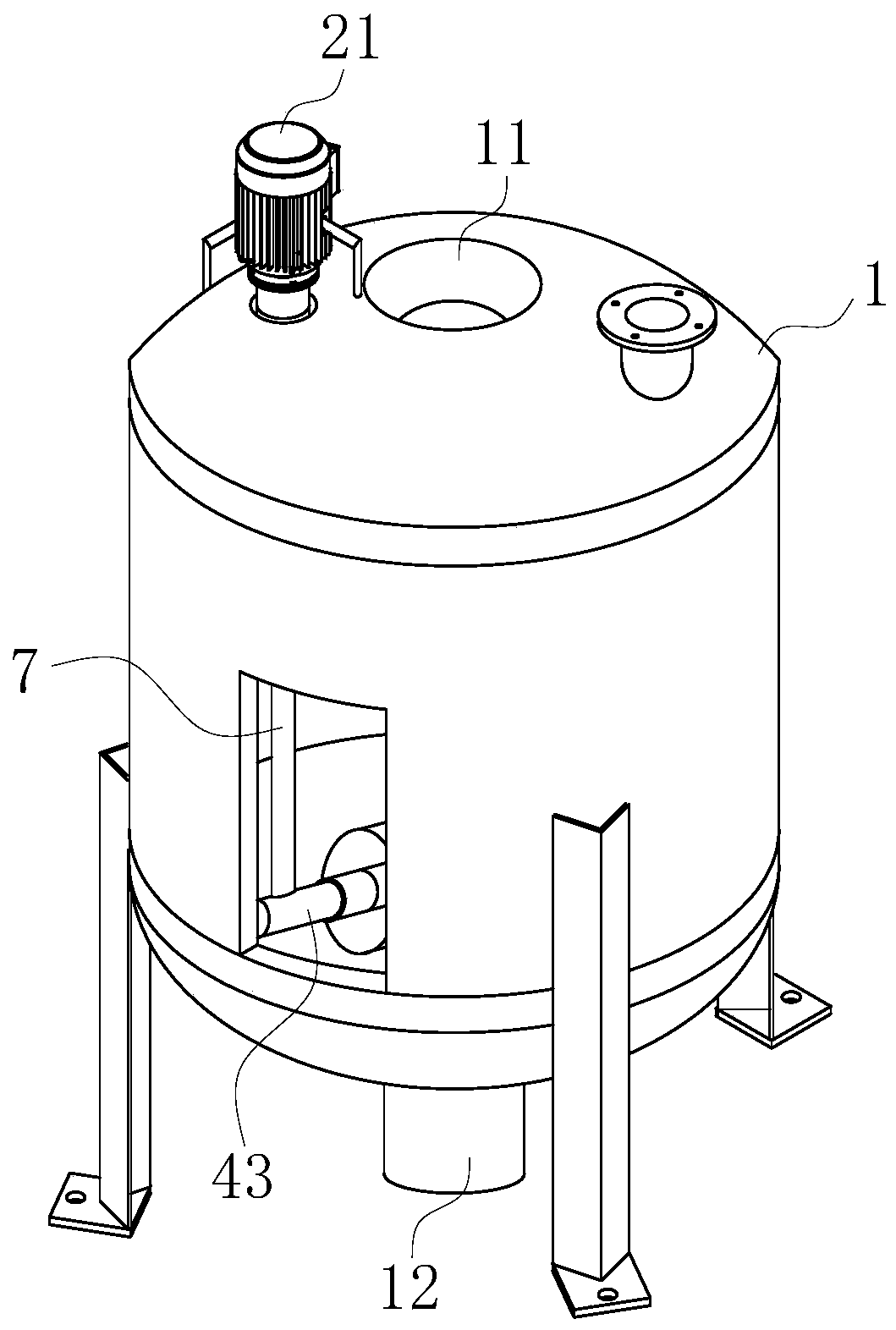

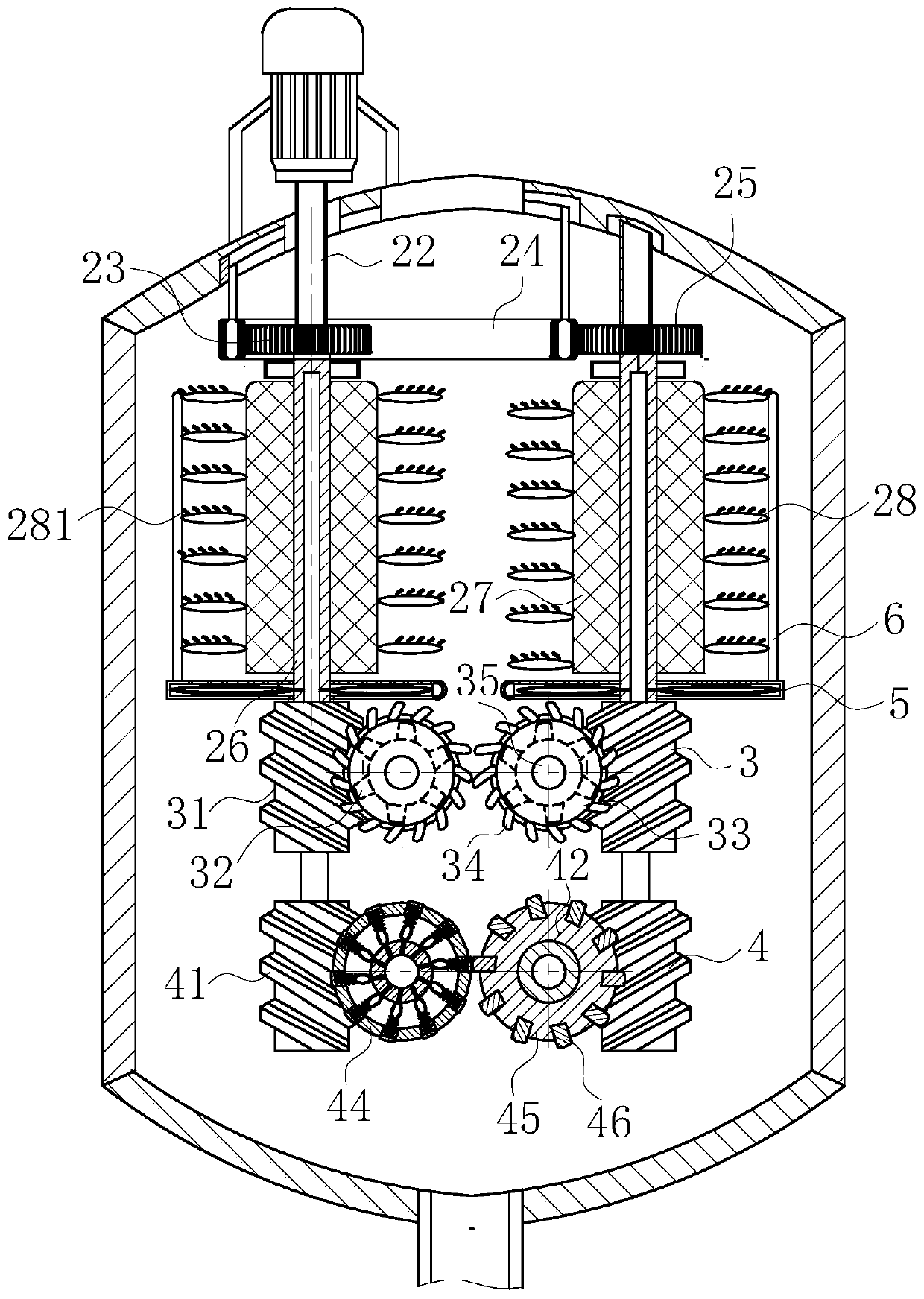

[0025] use Figure 1-Figure 5 A method for recycling light and thin steel scrap according to an embodiment of the present invention is described as follows.

[0026] Such as Figure 1-Figure 5 Shown, a kind of light and thin class steel scrap recycling method described in the present invention, this method comprises the following steps:

[0027] S1: Scrap steel recycling: Recycle light and thin scrap steel pipes or steel columns with a thickness of 2-4mm produced in living or production workshops;

[0028] S2: Scrap steel processing: the light and thin steel scrap recovered in S2 is processed into spherical or massive scrap steel through the scrap steel processing device;

[0029] S3: Furnace steelmaking: The light and thin steel scrap processed into spherical or block shape is sent to the hearth of the blast furnace through the belt, and as the iron ore gradually reaches the hearth of the blast furnace from the furnace top, it becomes molten iron, and the production of ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com