Novel bionic 3D printing bioactive fusion cage and preparation method thereof

A 3D printing and bioactive technology, which is applied in the field of new bionic 3D printing bioactive fusion devices and the production field, can solve the problems such as the inability to continuously release low concentrations of rhBMP-2, achieve the optimization of three-dimensional structure and mechanical properties, and reduce the end plate Stress, the effect of optimizing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

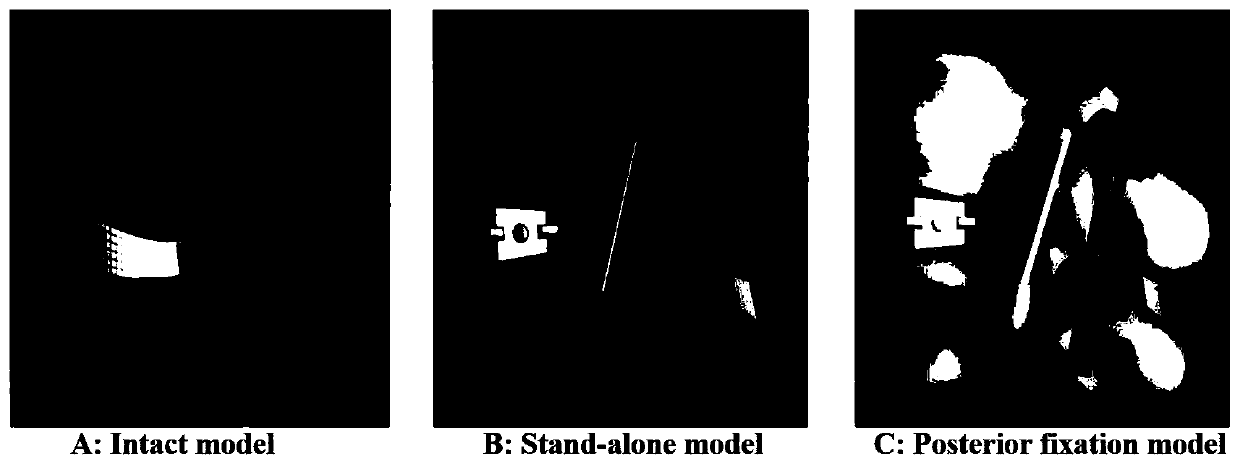

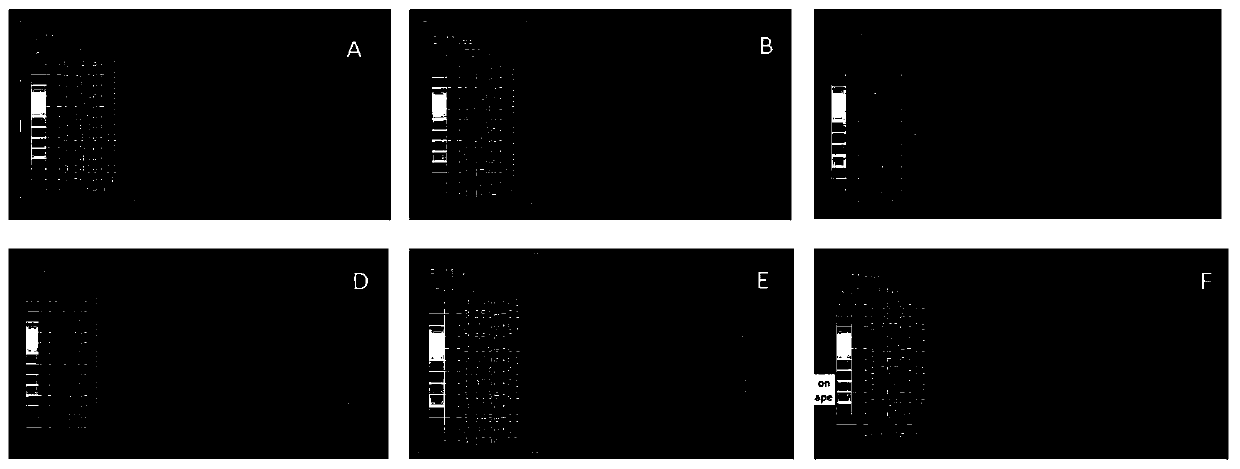

Method used

Image

Examples

Embodiment 1

[0054] A novel biomimetic 3D printing bioactive fuser is prepared by the following method:

[0055] (1) prepare 23% PLLA macromolecule 1,4-dioxane solution;

[0056] (2) Mix 18% n-HA with a particle size of 45nm into the PLLA polymer solution prepared in step (1), stir and vibrate vigorously for 6 hours to fully disperse n-HA to obtain PLLA / n-HA basic solution;

[0057] (3) Use low-temperature 3D printing technology to print porous anatomical fusion cages, and vacuum freeze-dry to remove organic solvents in the scaffolds to form porous anatomical fusion cages;

[0058] (4) First, dissolve 18 mg of PLGA in 6 mL of dichloromethane solvent, mix 5 mg of rhBMP-2 with 0.8 mL of distilled water, mix and stir the PLGA solution and rhBMP-2 solution, and add 8 mL of 1.5% polyvinyl alcohol As an emulsifier, carry out the first emulsification in the ultrasonic emulsification machine for 45 seconds, then pause for 10 minutes, perform the second emulsification in the ultrasonic emulsifica...

Embodiment 2

[0063] A novel biomimetic 3D printing bioactive fuser is prepared by the following method:

[0064] (1) prepare 25% PLLA macromolecule 1,4-dioxane solution;

[0065] (2) Mix 20% n-HA with a particle size of 50nm into the PLLA polymer solution prepared in step (1), stir and vibrate vigorously for 6 hours to fully disperse n-HA to obtain PLLA / n-HA basic solution;

[0066] (3) Use low-temperature 3D printing technology to print porous anatomical fusion cages, and vacuum freeze-dry to remove organic solvents in the scaffolds to form porous anatomical fusion cages;

[0067] (4) First, dissolve 19 mg of PLGA in 7 mL of dichloromethane solvent, mix 6 mg of rhBMP-2 with 0.9 mL of distilled water, mix and stir the PLGA solution and rhBMP-2 solution, and add 9 mL of 1.8% polyvinyl alcohol As an emulsifier, carry out the first emulsification in the ultrasonic emulsification machine for 45 seconds, then pause for 10 minutes, perform the second emulsification in the ultrasonic emulsifica...

Embodiment 3

[0072] (1) prepare 28% PLLA macromolecule 1,4-dioxane solution;

[0073] (2) Mix 23% of n-HA with a particle size of 55nm into the PLLA polymer solution prepared in step (1), stir and vibrate vigorously for 6 hours to fully disperse n-HA to obtain PLLA / n-HA basic solution;

[0074] (3) Use low-temperature 3D printing technology to print porous anatomical fusion cages, and vacuum freeze-dry to remove organic solvents in the scaffolds to form porous anatomical fusion cages;

[0075] (4) First, dissolve 20 mg of PLGA in 8 mL of dichloromethane solvent, mix 7 mg of rhBMP-2 with 1 mL of distilled water, mix and stir the PLGA solution and rhBMP-2 solution, add 10 mL of 2% polyvinyl alcohol The aqueous solution is used as an emulsifier to carry out the first emulsification in the ultrasonic emulsification machine for 45 seconds, then pause for 10 minutes, perform the second emulsification in the ultrasonic emulsification machine for 8 minutes, and then carry out centrifugal evaporatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com