Clamp device of pressing ring of optical lens

An optical lens and fastening device technology, applied in optics, optical components, installation, etc., can solve the problems of difficult balance and stability of human hands, operator injury, damage to the appearance of the lens, etc., and achieve the effect of improving quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings.

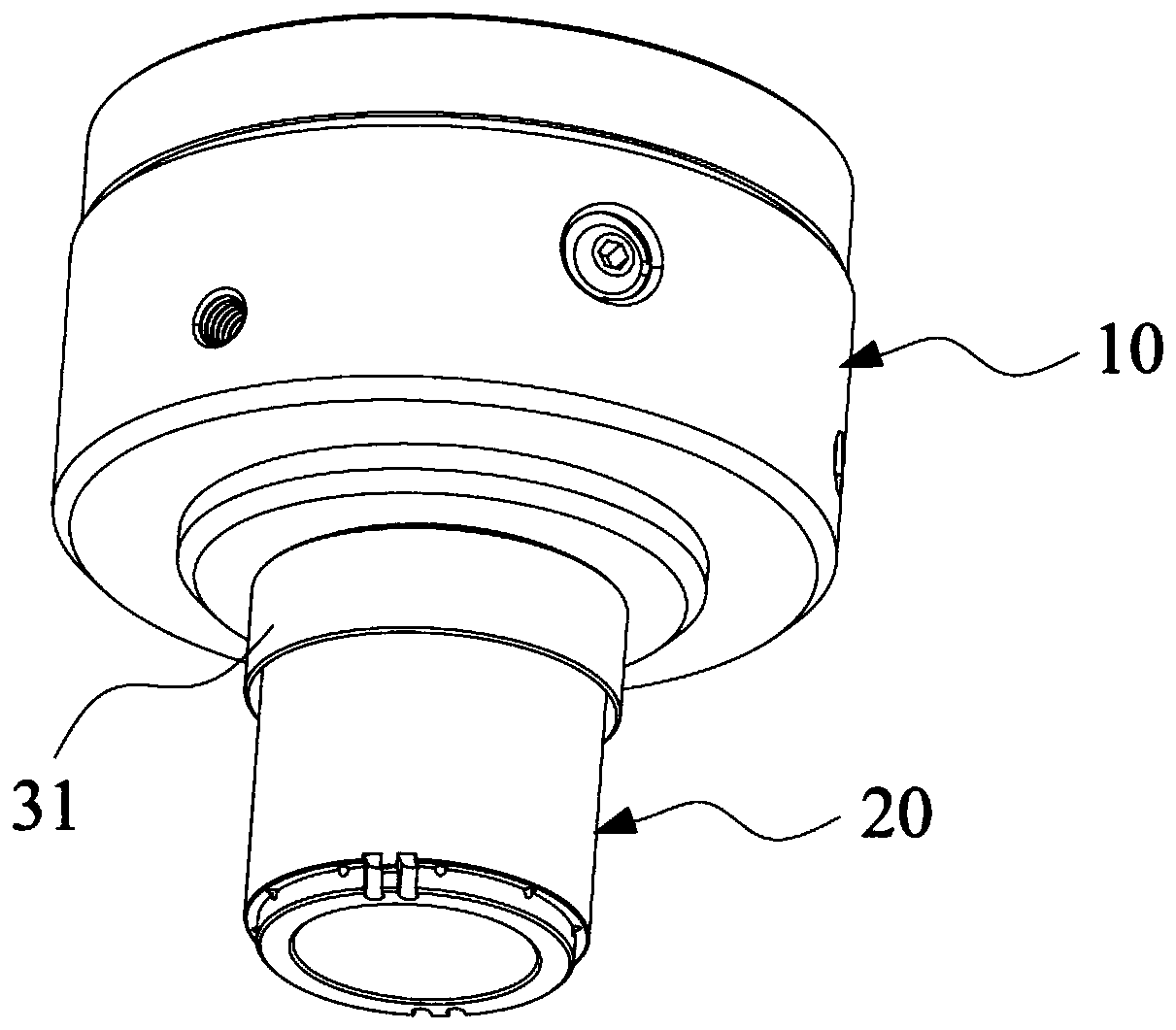

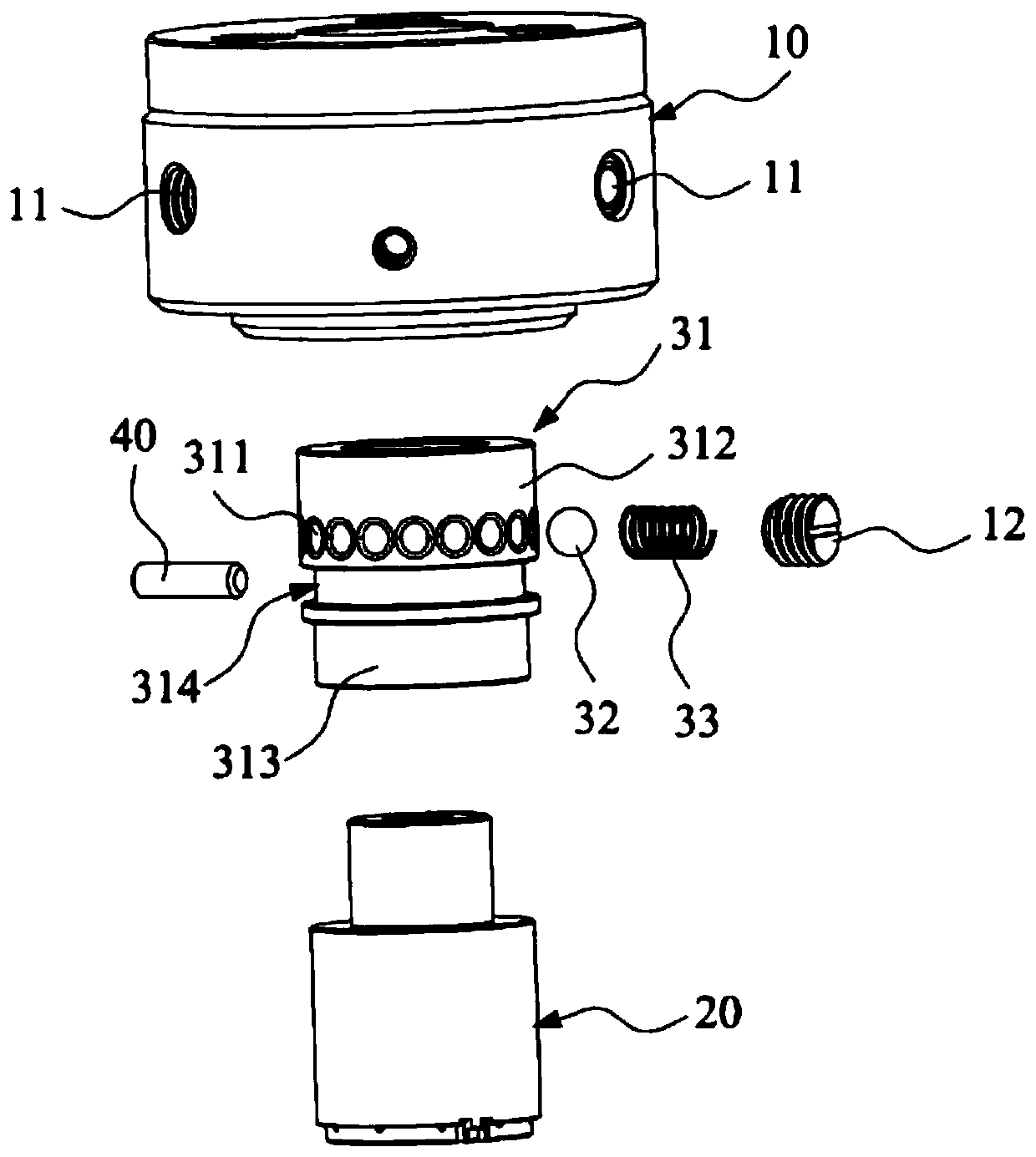

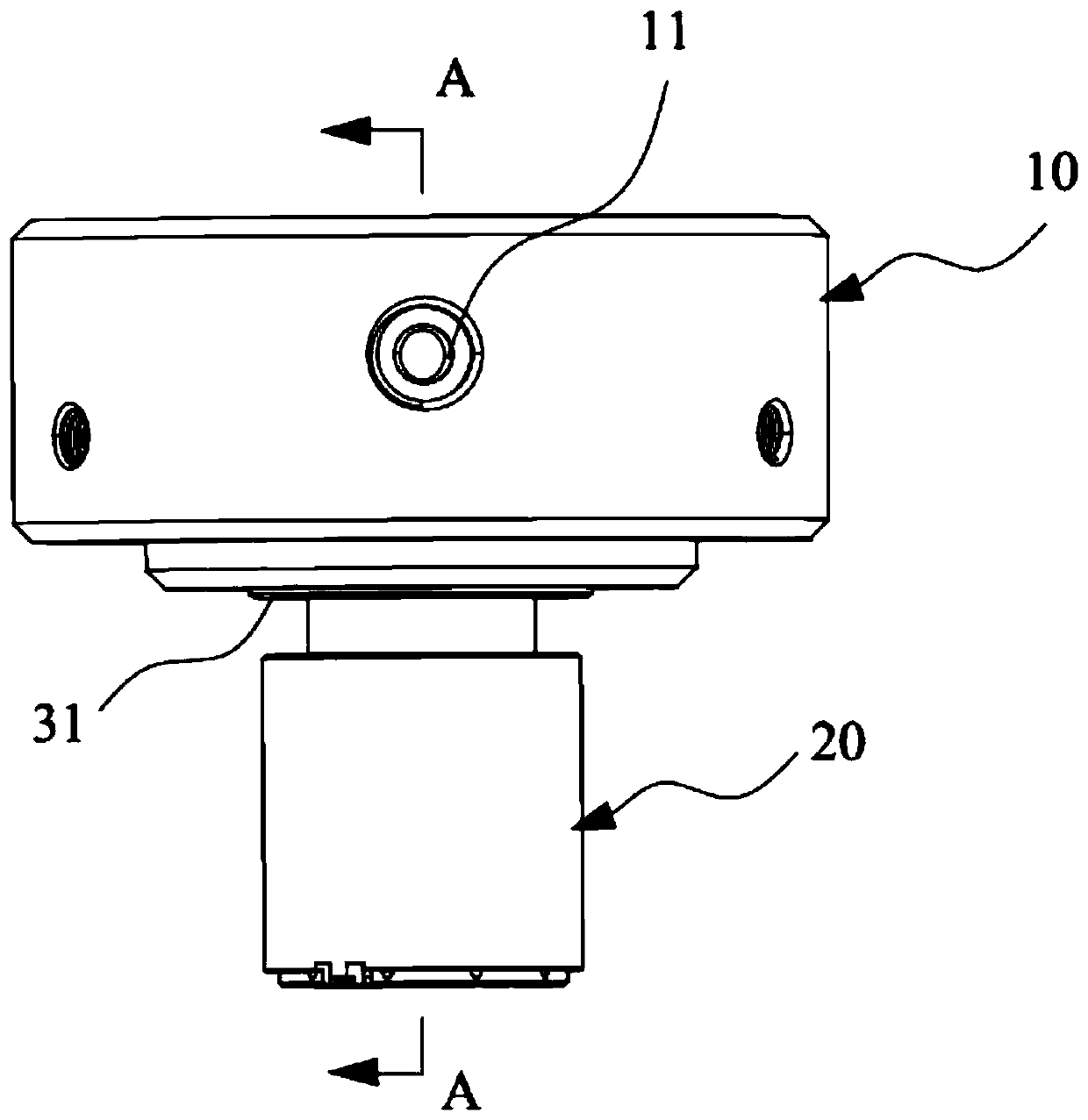

[0037] Such as Figure 1 to Figure 12 As shown, the optical lens clamping ring fastening device includes a fixing seat 10, a tightening mechanism 20 and a torque regulating mechanism. Wherein, the tightening mechanism 20 is used to tighten the pressure ring of the optical lens; the torque regulating mechanism is used to regulate the rotational torque of the tightening mechanism 20, and the torque regulating mechanism includes a connecting piece 31 and a ball 32, and the connecting piece 31 is connected to the tightening mechanism 20 respectively. and the fixed seat 10, and can drive the tightening mechanism 20 to rotate relative to the fixed seat 10;

[0038] The fixed seat 10 is provided with a cylindrical channel passing through the fixed seat 10, the connecting piece 31 includes a cylindrical first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com