A cold-formed hot-rolled pickling high-strength steel antirust liquid, its preparation method and application

A technology for hot-rolling pickling and anti-rust solution, which is applied in the field of cold-forming hot-rolling pickling high-strength steel anti-rust solution, can solve the problems of high-strength steel being easy to rust, etc., and achieves excellent anti-rust performance, simple operation and good mechanics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

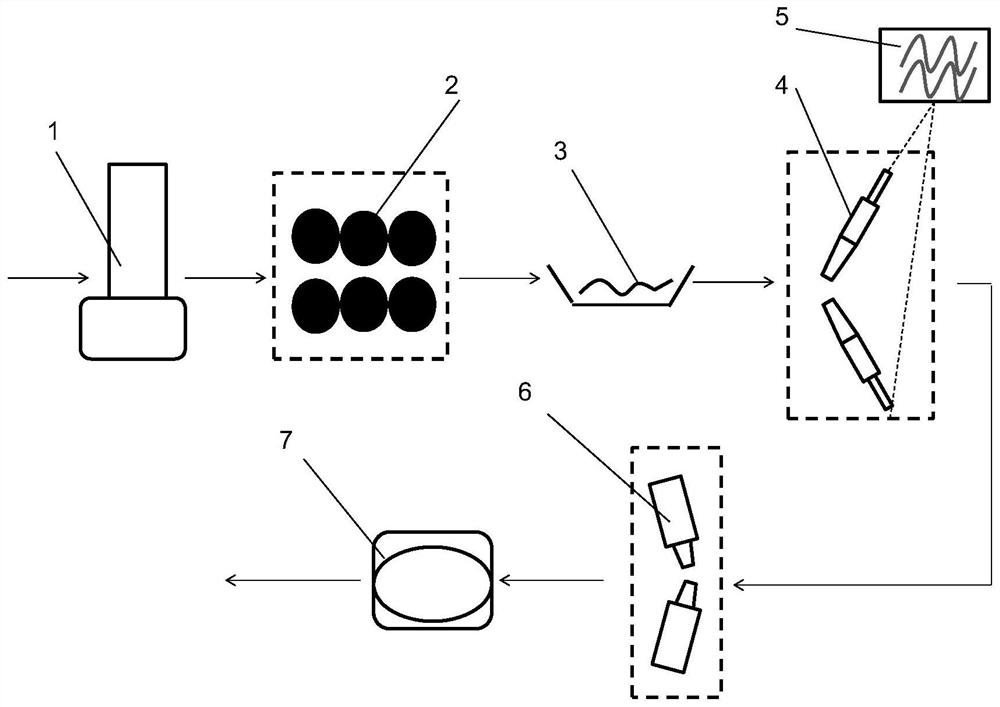

Image

Examples

Embodiment 1

[0045] Embodiment 1 The preparation method of a kind of cold-forming hot-rolled pickling high-strength steel antirust liquid of the present invention:

[0046] 1) Preparation of microemulsion

[0047] Add glucose and fatty acid methyl ester in propylene glycol, the add-on of glucose is 32 grams in every liter of propylene glycol solution, and the add-on of fatty acid methyl ester is 51 grams in every liter of propylene glycol solution.

[0048] Under the condition of temperature of 150 DEG C and pressure of 0.6MPa, stirring rapidly for 2 hours, a microemulsion is formed, and glucose and fatty acid methyl ester form sucrose fatty acid ester through transesterification in the microemulsion environment.

[0049] 2) Prepare phosphoric acid mixture

[0050] Prepare a phosphoric acid solution with a concentration of 1.1%, add lauric acid monoester 135mg / L, palmitic acid monoester 230mg / L and stearic acid triester 160mg / L to the phosphoric acid solution, stir for 35 minutes at a spe...

Embodiment 2

[0063] A kind of preparation method of cold-forming hot-rolled pickling high-strength steel antirust liquid of the present invention:

[0064] 1) Preparation of microemulsion

[0065] Glucose and fatty acid methyl esters were added to propylene glycol in an amount of 42 grams per liter of propylene glycol for glucose and 38 grams of fatty acid methyl esters per liter of propylene glycol.

[0066] At a temperature of 147°C and a pressure of 0.7 MPa, stir rapidly for 3 hours to form a microemulsion. Glucose and fatty acid methyl esters form sucrose fatty acid esters through transesterification in the microemulsion environment. 2) Preparation of phosphoric acid mixture

[0067] Preparation concentration is the phosphoric acid solution of 1.7wt.%, in the phosphoric acid solution of 1.7wt.%, add lauric acid monoester 111mg / L, palmitic acid monoester 220mg / L and stearic acid triester 145mg / L, with 125 rev / minute speed stirring for 35 minutes to obtain a phosphoric acid mixture.

...

Embodiment 3

[0078] Embodiment 3 The preparation method of a kind of cold-forming hot-rolled pickling high-strength steel antirust liquid of the present invention:

[0079] 1) Preparation of microemulsion

[0080] Add glucose and fatty acid methyl ester in propylene glycol, the add-on of glucose is 15 grams in every liter of propylene glycol solution, and the add-on of fatty acid methyl ester is 25 grams in every liter of propylene glycol solution.

[0081] Under the condition of temperature of 150 DEG C and pressure of 0.6MPa, stirring rapidly for 2 hours, a microemulsion is formed, and glucose and fatty acid methyl ester form sucrose fatty acid ester through transesterification in the microemulsion environment.

[0082] 2) Prepare phosphoric acid mixture

[0083] Prepare a phosphoric acid solution with a concentration of 0.5%, add lauric acid monoester 40mg / L, palmitic acid monoester 150mg / L and stearic acid triester 98mg / L to the phosphoric acid solution, and stir for 35 minutes at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com