Preparation method of coralline high-purity tantalum powder

A coral-like and high-purity technology is applied in the field of preparation of coral-like high-purity tantalum powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

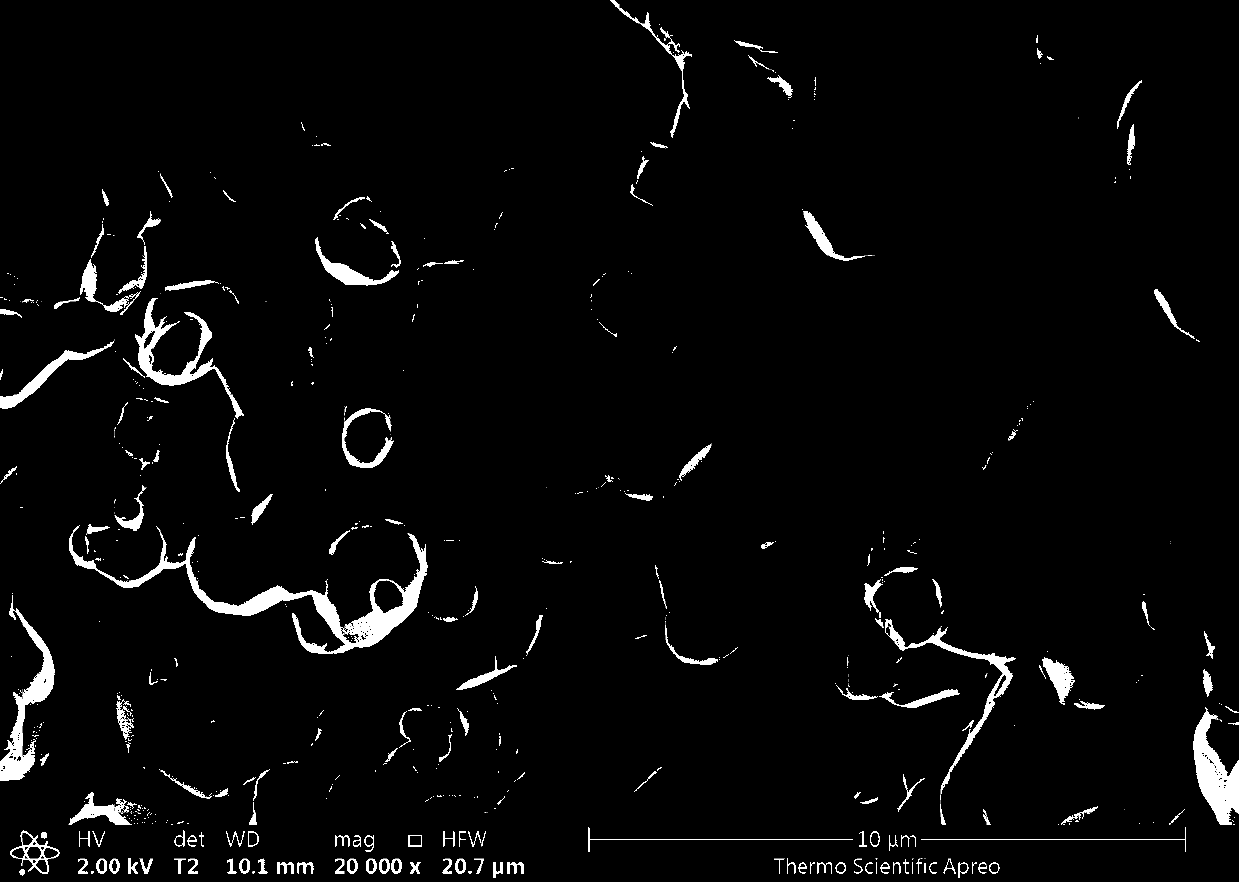

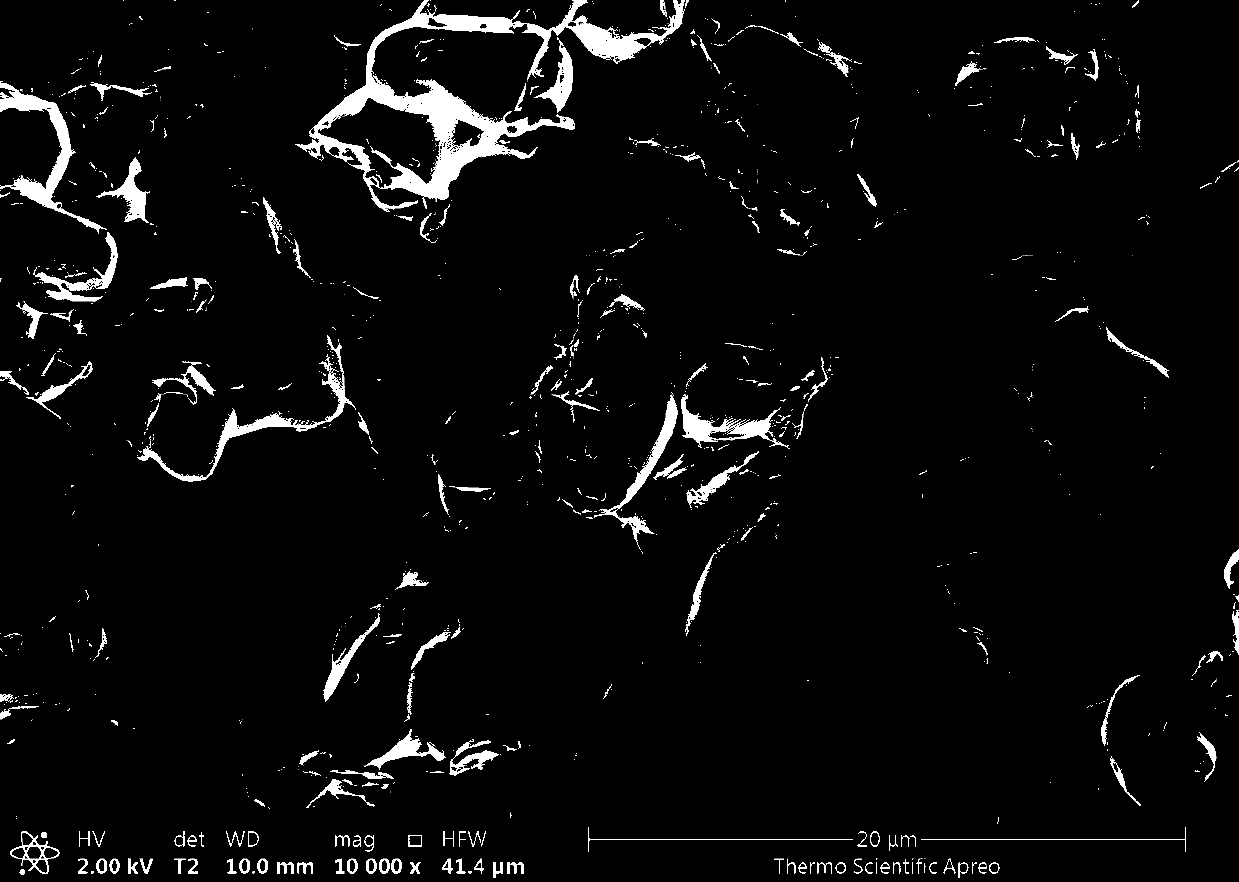

Image

Examples

Embodiment 1

[0034] The preparation method of coral-shaped high-purity tantalum powder comprises the following steps:

[0035] (1) Heat needle-shaped high-purity potassium fluorotantalate to 350°C for 10 hours in a vacuum activation furnace to activate the needle-shaped potassium fluorotantalate into powdery high-purity potassium fluorotantalate. Among them, high-purity fluorotantalate W content in potassium tantalate ≤ 1ppm, Mo content ≤ 1ppm, Nb content ≤ 1ppm;

[0036] (2) Heat the diluent NaCl to 60°C in a drying oven for 22 hours, so that NaCl does not contain moisture;

[0037] (3) Filter and purify metallic sodium through a molten sodium system to obtain purified sodium, in which Na≥99.9w / w%, K≤0.003w / w%, Fe≤0.001w / w%, and heavy metals≤0.005w / w%, C content ≤ 30ppm, the filtration and purification process of the molten sodium system is as follows: heat the metal sodium to 150°C for melting, then remove oil at 130°C and -0.08MPa vacuum, and use a stainless steel mesh for coarse filt...

Embodiment 2

[0044] The preparation method of coral-shaped high-purity tantalum powder comprises the following steps:

[0045] (1) Heat the needle-shaped high-purity potassium fluorotantalate in a vacuum activation furnace to 300°C for 8 hours to activate the needle-shaped potassium fluorotantalate into powdery high-purity potassium fluorotantalate. W content in potassium tantalate ≤ 1ppm, Mo content ≤ 1ppm, Nb content ≤ 1ppm;

[0046] (2) Heat the diluent NaCl to 100°C in a drying oven for 20 hours, so that NaCl does not contain moisture;

[0047] (3) Filter and purify metallic sodium through a molten sodium system to obtain purified sodium, in which Na≥99.9w / w%, K≤0.003w / w%, Fe≤0.001w / w%, and heavy metals≤0.005w / w%, C content ≤ 30ppm, the filtration and purification process of the molten sodium system is as follows: heat the metal sodium to 150°C for melting, then remove oil at 130°C and -0.08MPa vacuum, and use a stainless steel mesh for coarse filtration at 130°C Then use a ceramic ...

Embodiment 3

[0054] The preparation method of coral-shaped high-purity tantalum powder comprises the following steps:

[0055] (1) Heat needle-shaped high-purity potassium fluorotantalate to 320°C for 12 hours in a vacuum activation furnace to activate the needle-shaped potassium fluorotantalate into powdery high-purity potassium fluorotantalate. Among them, high-purity fluorotantalate W content in potassium tantalate ≤ 1ppm, Mo content ≤ 1ppm, Nb content ≤ 1ppm;

[0056] (2) Heat the diluent NaCl in the drying oven to 80°C for 24 hours, so that NaCl does not contain moisture;

[0057] (3) Filter and purify metallic sodium through a molten sodium system to obtain purified sodium, in which Na≥99.9w / w%, K≤0.003w / w%, Fe≤0.001w / w%, and heavy metals≤0.005w / w%, C content ≤ 30ppm, the filtration and purification process of the molten sodium system is as follows: heat the metal sodium to 150°C for melting, then remove oil at 130°C and -0.08MPa vacuum, and use a stainless steel mesh for coarse fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com