Environment-friendly methylbenzene distillation kettle

A still, environmentally friendly technology, applied in distillation purification/separation, distillation in boiler/distillate, cleaning of hollow objects, etc., can solve the problem of difficult to clean the inner wall of the tank, the heating and mixing effect of the still is general, and it is inconvenient to observe the inside of the tank. situation and other problems, to achieve the effect of improving the heating and evaporation effect, being conducive to environmental protection and reducing the probability of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

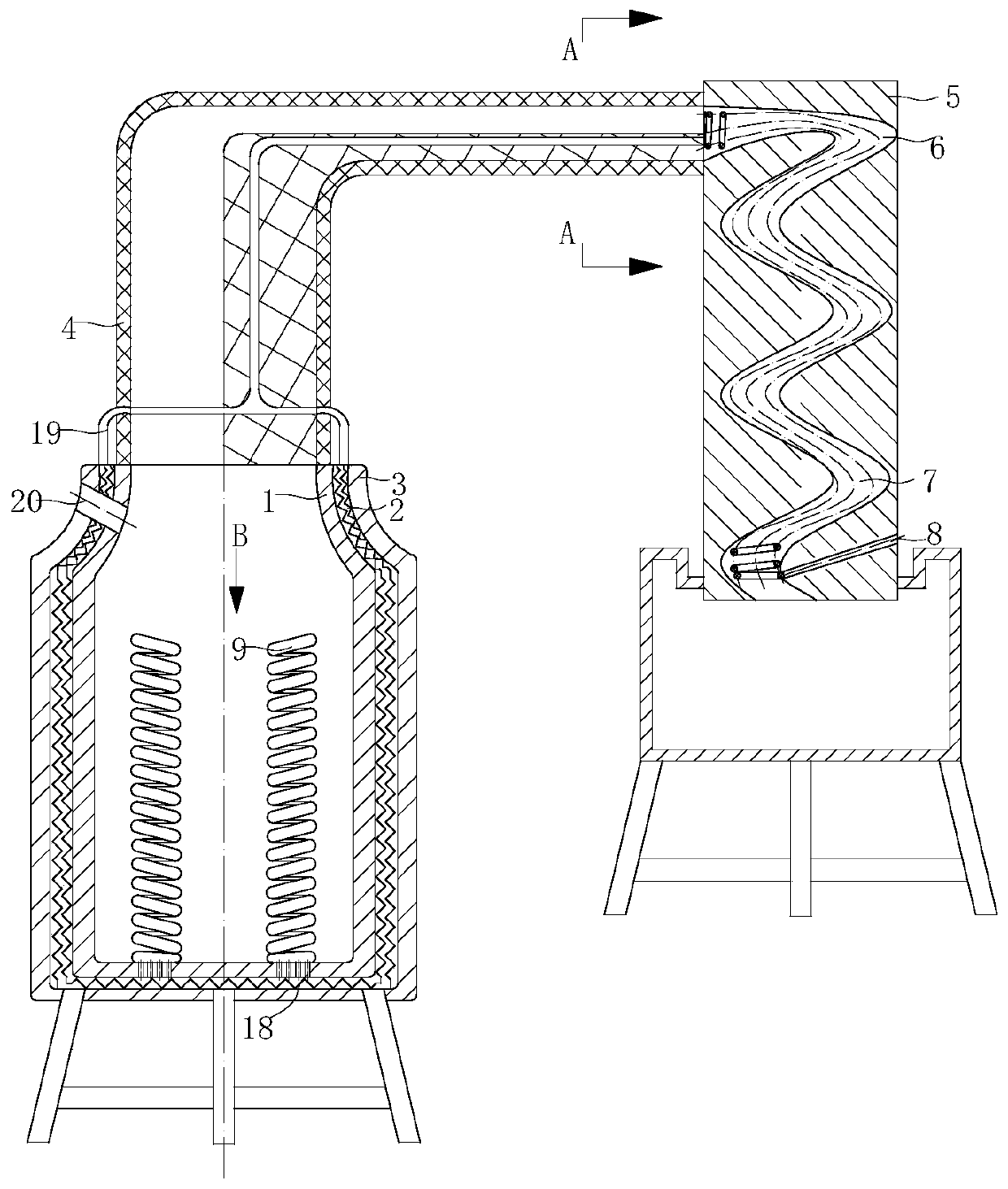

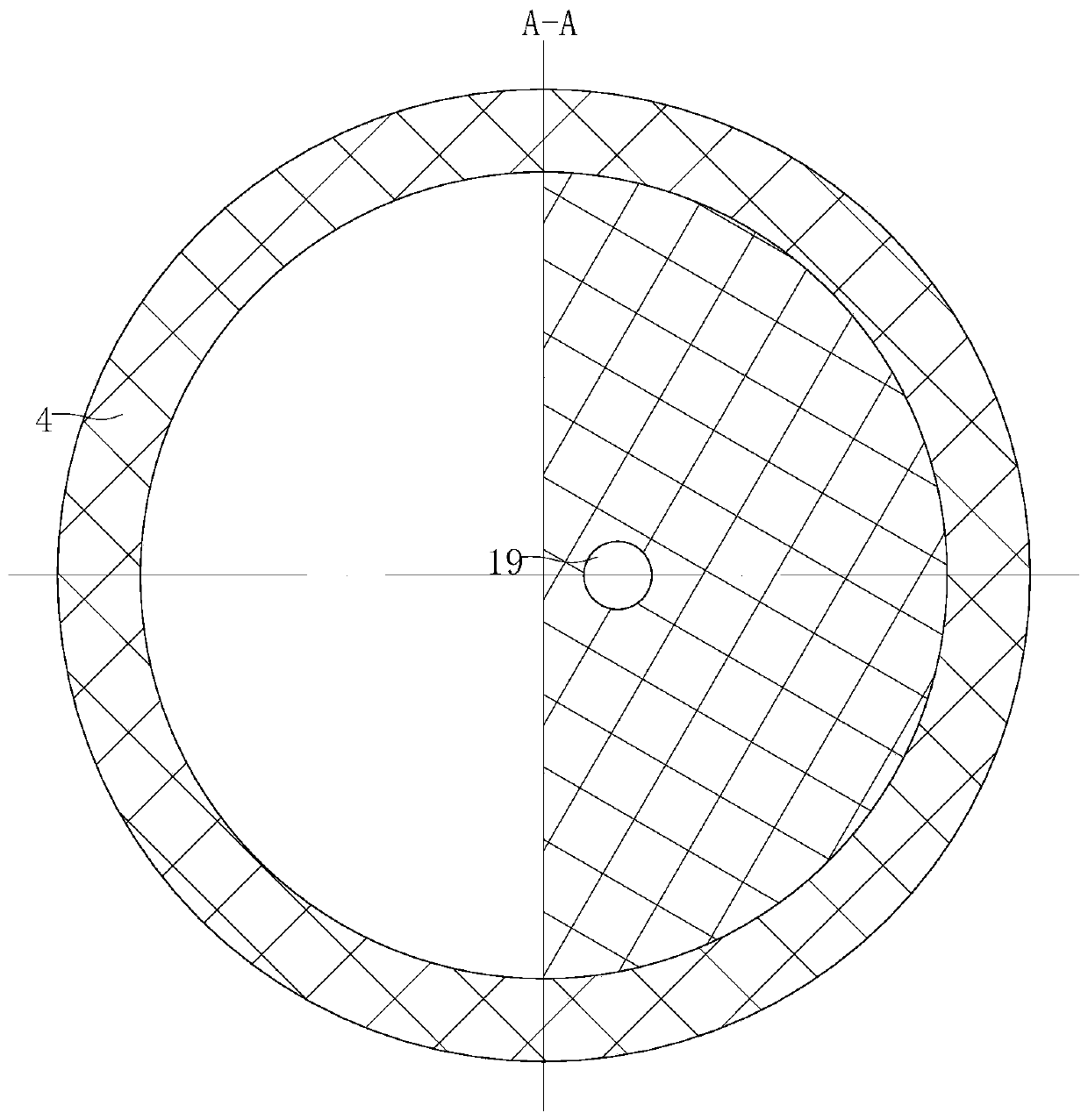

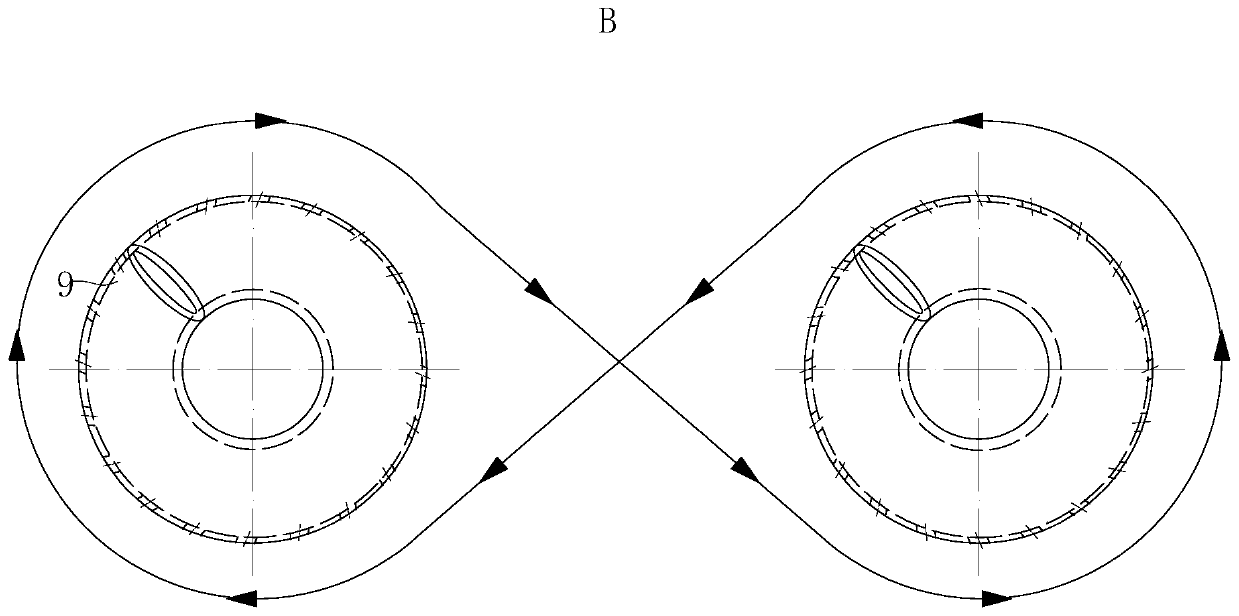

[0024] As an embodiment of the present invention, the inner bottom of the tank body 1 is fixed with evenly arranged spiral columns 9; the surface of the spiral column 9 is provided with evenly arranged openings 10, and the openings 10 are arranged obliquely; The bottom of the helical column 9 communicates with the heating layer 2 through the air port 18, and the heated air can enter the helical column 9 from the air port 18; during operation, the hot air enters the helical column 9 through the air port 18, and then enters from the opening 10 on the surface of the helical housing. In the tank body 1, in contact with the toluene liquid in the tank body 1, heat can be directly brought to the toluene liquid in the tank body 1, and at the same time, the toluene liquid can be stirred to make the toluene liquid fully mixed, which is conducive to improving the heating and evaporation effect; opening holes 10 is set obliquely, and the gas rushes out from the opening 10 to drive the near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com