Digital production method of cleft lip and palate alveolar shaping palate guard plate

A manufacturing method and technology for cleft lip and palate, which are applied in dentistry, orthodontics, prosthetics, etc., can solve the problems of unstable manufacturing accuracy, displacement of palate guards, and random treatment, so as to reduce the cost and manpower of follow-up visits. Cost-effective, simple production process, and improve the effect of orthodontic treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

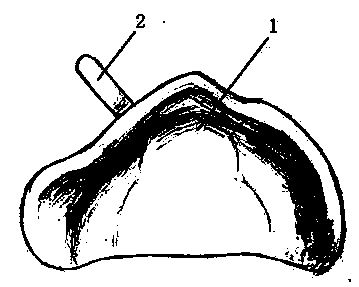

[0034] Cleft lip and palate alveolar shaping palate guard is a part of PNAM appliance.

[0035] The invention provides a digital manufacturing method of cleft lip and palate alveolar shaping palate guard, which comprises the following steps:

[0036] S1. Obtain the digital model:

[0037] Use a 3D scanner to directly scan the patient's mouth or scan the oral model to obtain a digital model of the alveolar bone shape in the patient's mouth.

[0038] S2. Virtual digital design of palate guard:

[0039] According to the digital model, calibrate the jaw landmarks; then according to the law of jaw movement before and after treatment, mark the preoperative coordinates, postoperative coordinates and coordinate differences of the jaw landmarks, and decompose the coordinate difference of each landmark into 6 Up to step 8, get the state of the alveolar bone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com