Graphene-based composite material with surface coated by mesoporous silica and loaded with noble metal nanoparticles, as well as preparation method and application of graphene-based composite material

A technology of mesoporous silica and nanoparticles is applied in the field of preparation of nanocomposite materials, which can solve the problems of hindering the mass transfer process of substrates and products, covering the active site of catalytic reaction, weak interaction force, etc. Repeated use for many times, convenient for enrichment and recovery, and the effect of preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a graphene-based composite material coated with mesoporous silica and loaded with noble metal nanoparticles, comprising the following steps:

[0044] A total volume of 24 mL of 1.5 mmol L -1 Chloroplatinic acid, 0.8mg·L -1 Graphene oxide, 0.15mol L -1 The aqueous solution of urea was reacted in a 90°C water bath for 12h; then 16mL of C was added to it 16 Aqueous TABr solution (60mmol·L -1 ), put it into a 40°C water bath and add 3mmol tetraethyl orthosilicate, after 12 hours of reaction, wash it with ethanol three times, and dry it; reduce the obtained solid at 250°C under a hydrogen atmosphere to obtain nanoparticles, and use The hydrochloric acid / ethanol solution was refluxed for 12 hours, washed three times with ethanol and water, and dried to obtain the final product. The mass fraction of Pt in the catalyst was 5.1%.

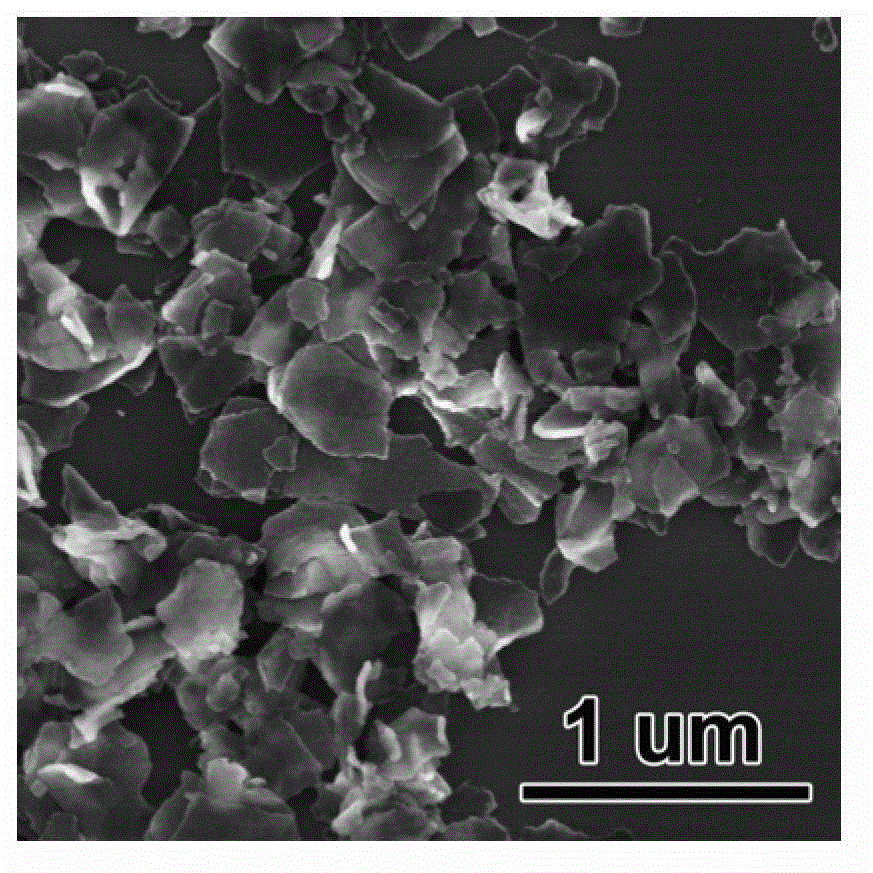

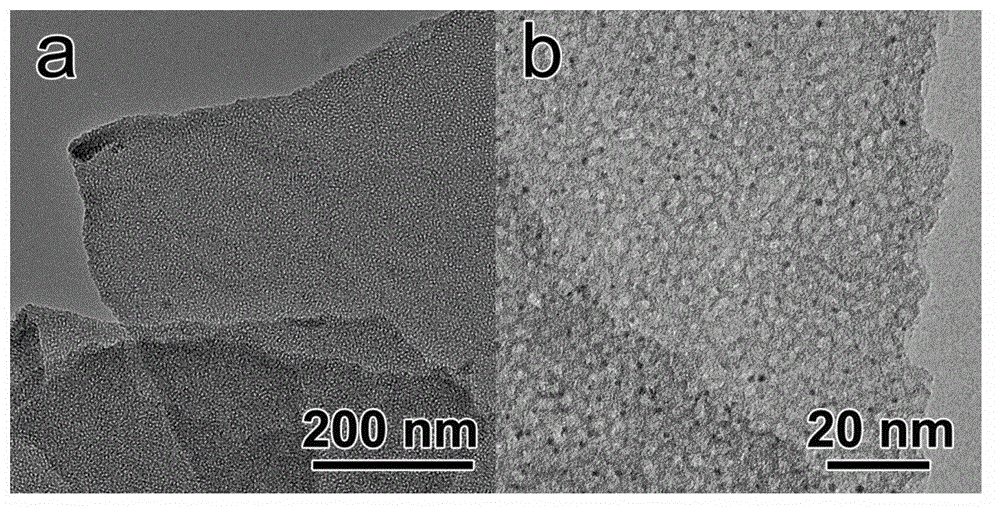

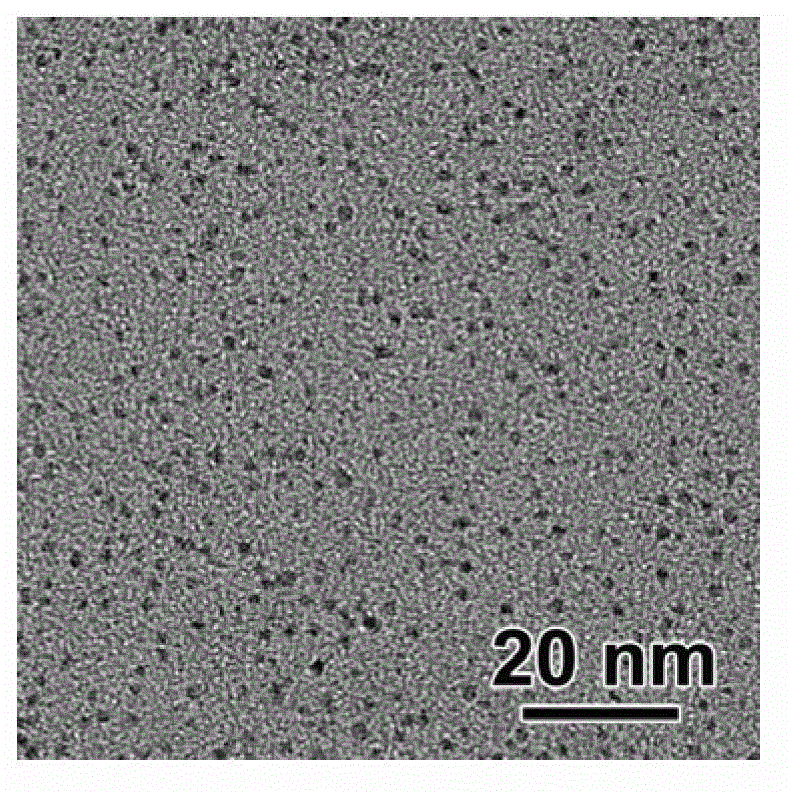

[0045] The prepared G / MmSiO 2 Characterized by scanning electron microscopy, figure 1 It is a scanning electron microsc...

Embodiment 2

[0051] Repeat Example 1 with the difference only in the H that will be added 2 PtCl 6 The solution was changed to PdCl 2 solution. The mass fraction of Pd in the obtained composite catalyst was 2.4%, and the diameter of the Pd nanoparticles was 1.8nm. The average diameter of mesoporous silica is 2.8 nm.

Embodiment 3

[0053] Repeat Example 1 with the difference only in the H that will be added 2 PtCl 6 The solution was changed to RuCl 3 solution. The mass fraction of Ru in the obtained composite catalyst was 2.3%, and the diameter of Ru nanoparticles was 1.4 nm. The average diameter of mesoporous silica is 2.8 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com