Preparation method of supercapacitor chip, supercapacitor chip and supercapacitor

A supercapacitor and chip technology, applied in the field of capacitors, can solve the problem that supercapacitor chips are difficult to meet the requirements of high voltage and high current applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

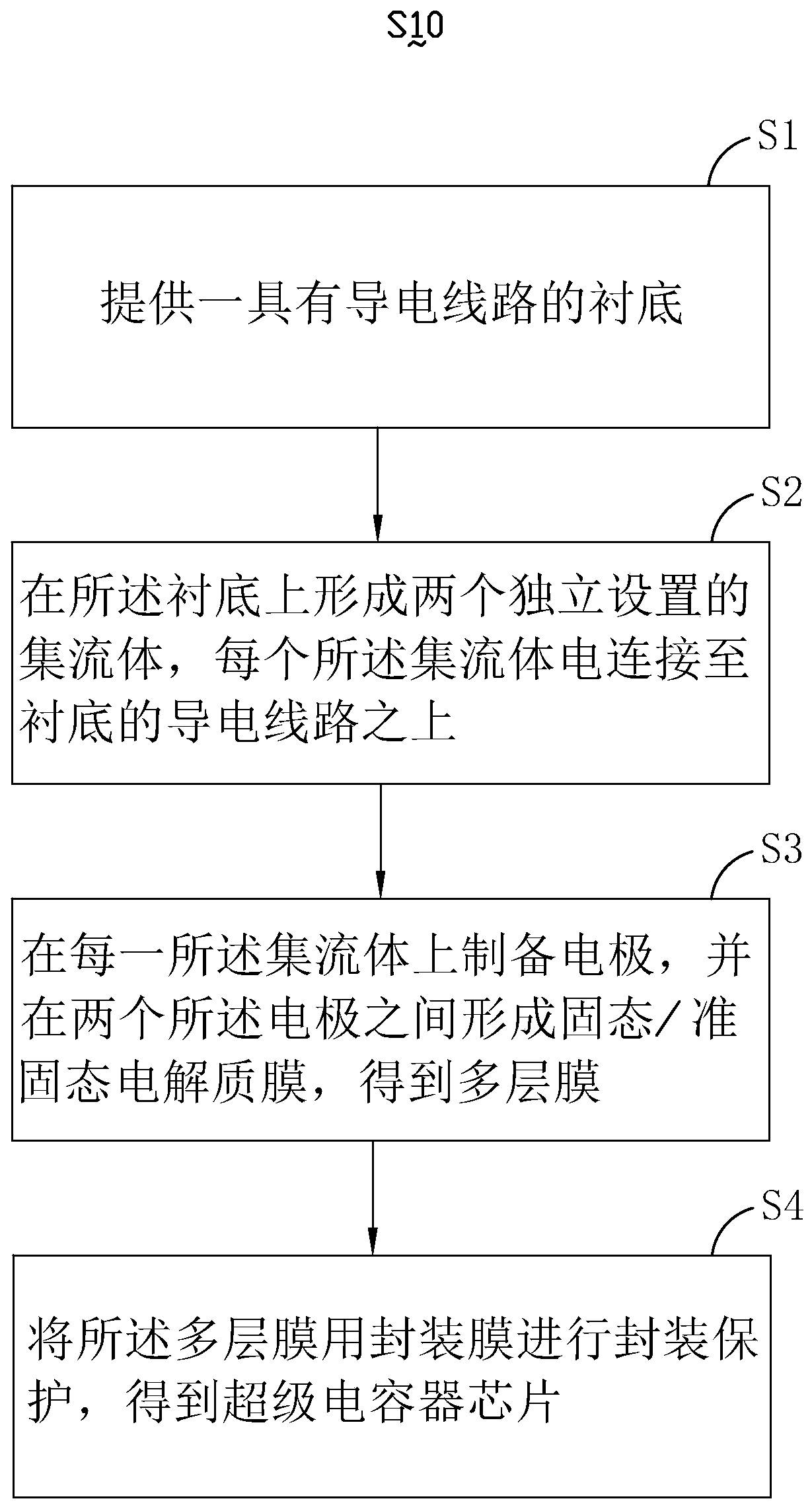

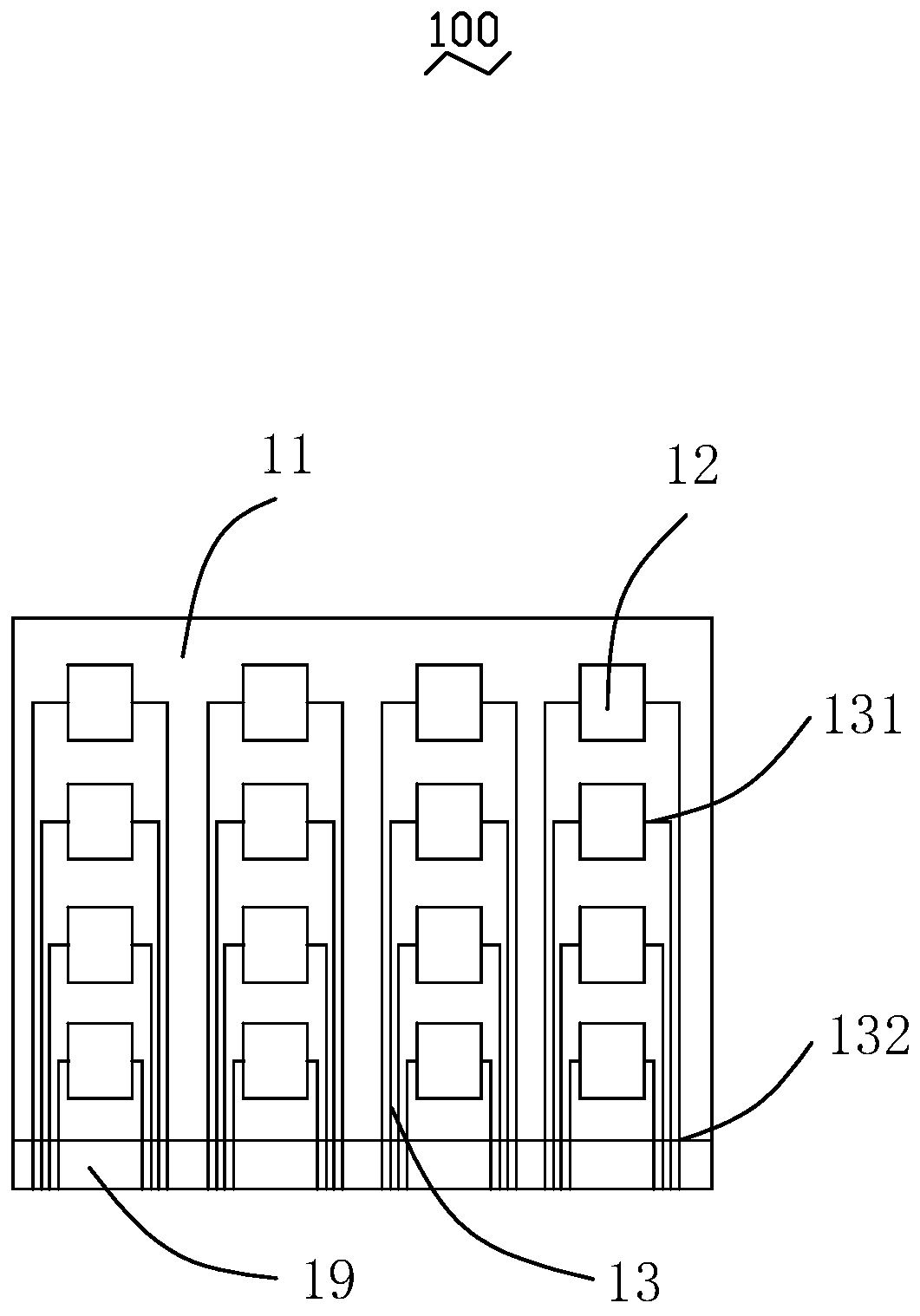

[0035] see figure 1 , the present invention provides a kind of preparation method S10 of supercapacitor chip, it comprises the following steps:

[0036] Step S1, providing a substrate 11 with conductive lines 13;

[0037] Step S2, forming two independently arranged current collectors 14 on the substrate 11, each of the current collectors 14 is electrically connected to the conductive circuit 13 of the substrate 11; and

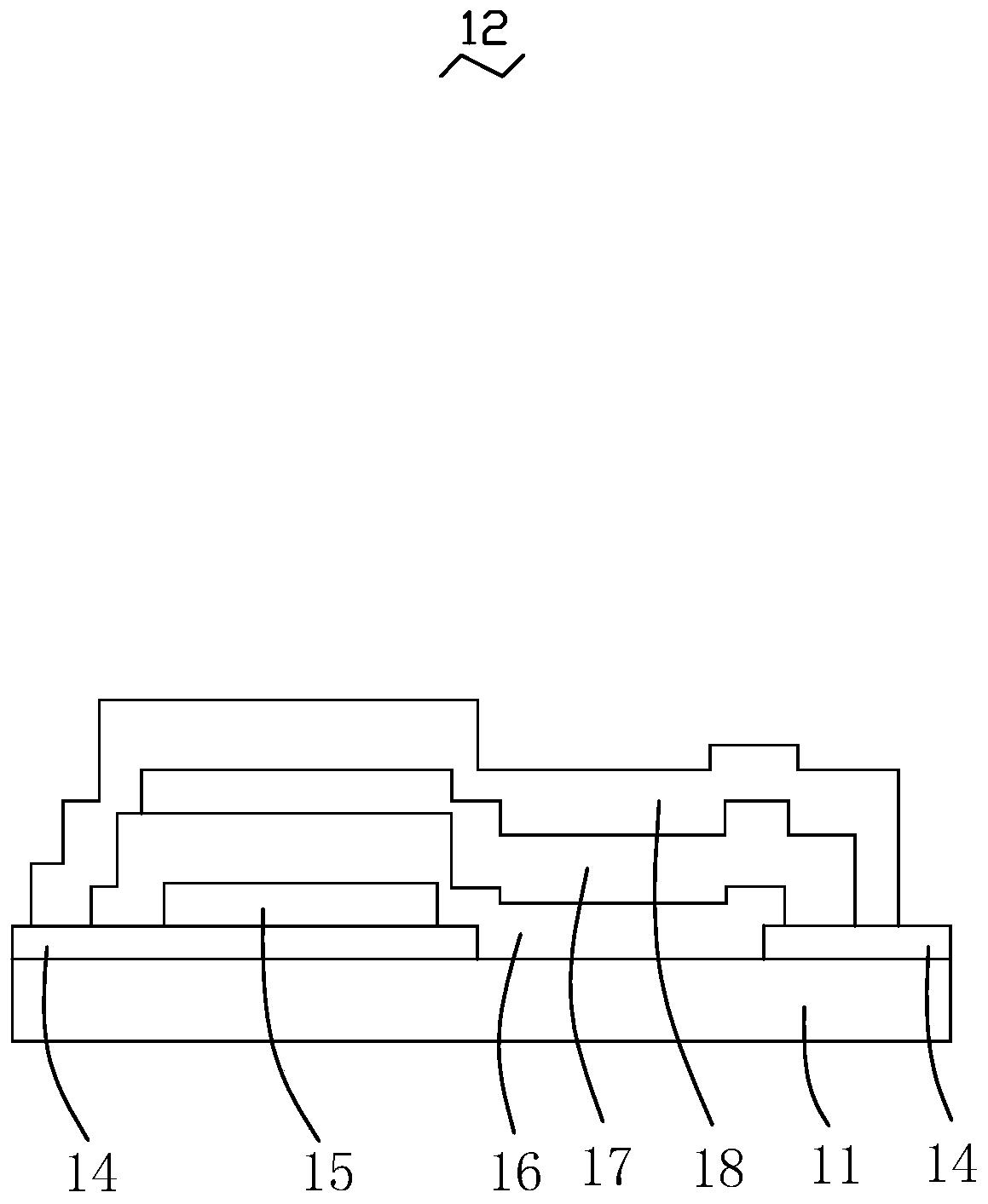

[0038] Step S3, preparing a positive electrode 15 on one of the current collectors 14, preparing a negative electrode 17 on the other current collector 14, and forming a solid / quasi-solid electrolyte film 16 between the positive electrode 15 and the negative electrode 17 , to obtain a multilayer film;

[0039] Step S4 , encapsulating and protecting the multilayer film with an encapsulating film 18 to obtain a supercapacitor chip 12 .

[0040] It should be noted here that the current collector 14, the positive electrode 15 / negative electrode 17, the solid / quas...

specific Embodiment

[0046] Further, the present invention also provides a specific embodiment of preparing supercapacitor chip 12, comprising the following steps:

[0047] Step 1: Prepare a substrate 11 made of a PET film, wash the surface of the PET film with ethanol, dry it in vacuum at 80° C. for 2 hours, and set aside.

[0048] Step 2: Print two current collectors 14 on the substrate 11 by screen printing. The material of the two current collectors 14 is metallic copper. The specific screen printing copper paste has a solid content of 70-80% and a viscosity of 1000-5000mPa·s, bake at 100°C for more than 10min, and the thickness is 0-500nm.

[0049] Step 3: Screen print the positive electrode 15 on the current collector 14. The material selected for the positive electrode 15 is carbon. The specific carbon paste has a viscosity of 1000-5000 mPa·s, baked at 120°C for 15 minutes, and has a thickness of 0-500 mPa·s. 1um.

[0050] Step 4: Screen-print the solid electrolyte membrane 16 on the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com