Fabricated steel structure beam and column connection joint and construction method

A technology of beam-column connection and steel structure, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve problems such as falling off and low connection strength, and achieve the effect of consuming earthquake energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

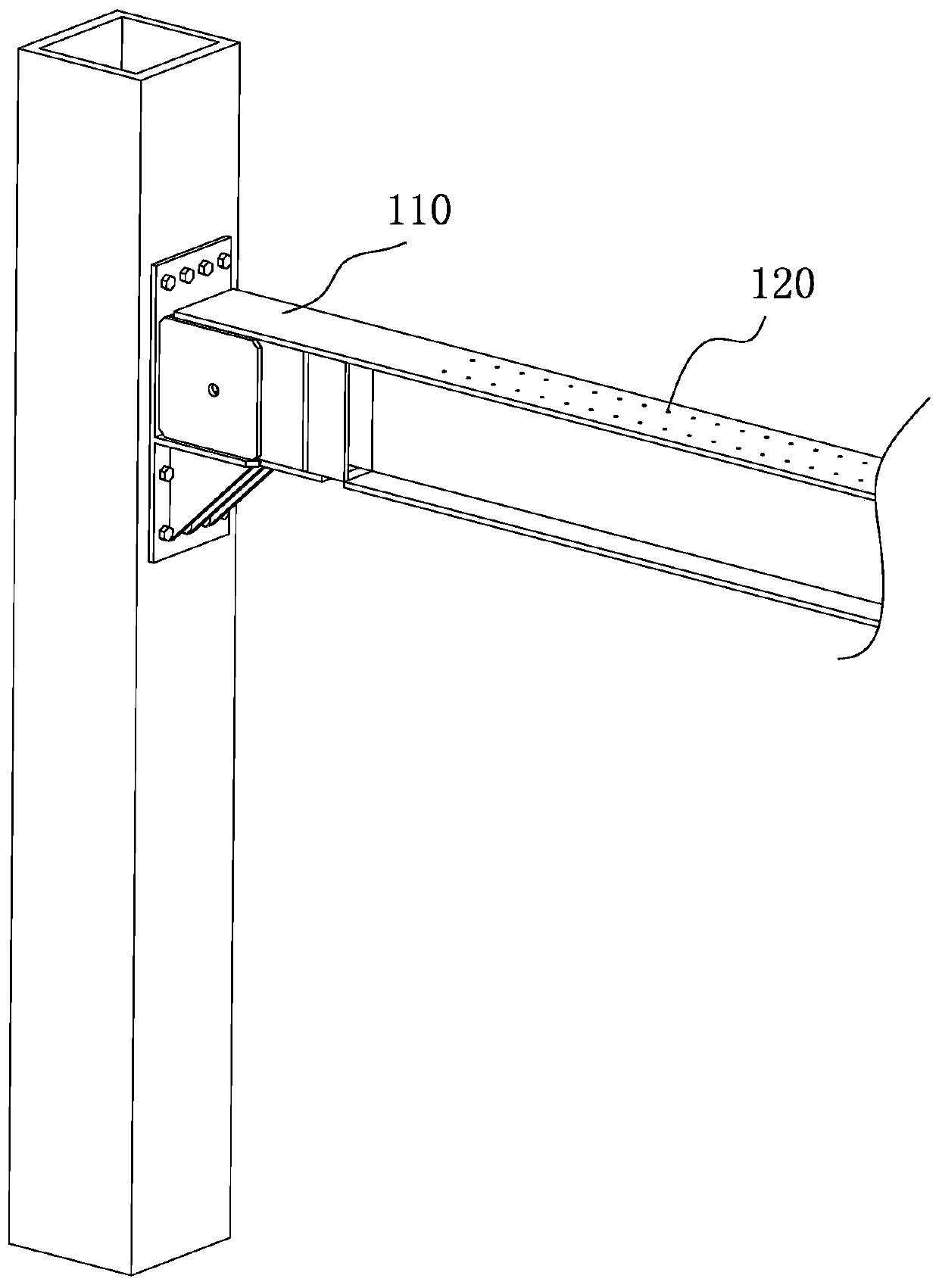

[0049] The steel beam in this embodiment is an I-shaped steel structure, which is the same as a common I-shaped beam. The steel beam in this embodiment is also composed of a web and a flange, wherein a hollowed-out circular hole can also be set on the web. To further reduce the self-weight of the steel beam, the round hole is composed of a large round hole and a small round hole. This hollowed-out structure can further optimize the amount of steel used in steel structures without reducing the strength.

[0050] This embodiment is attached in conjunction with the instructions figure 1 To attach Figure 10 Give a detailed explanation.

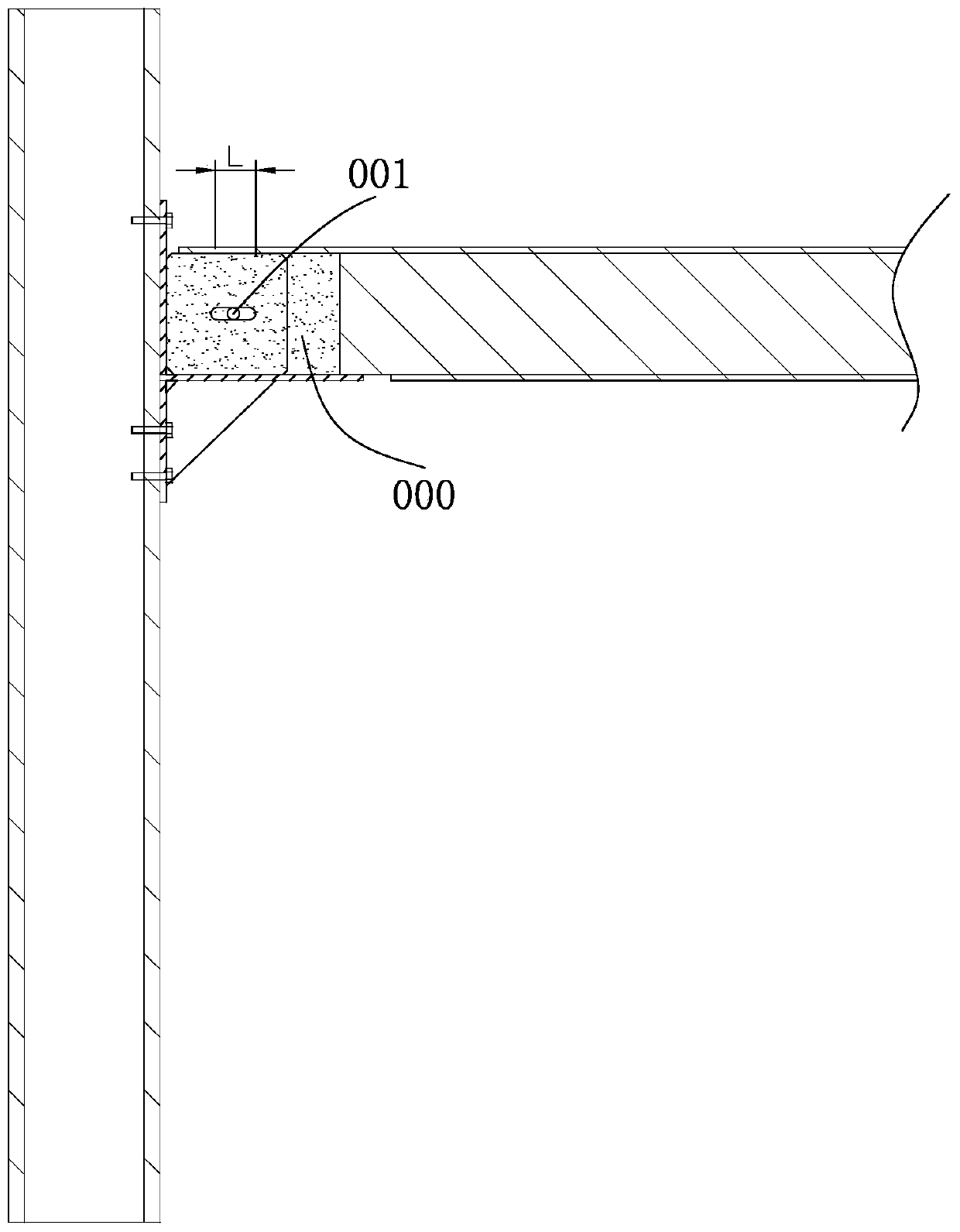

[0051] The two ends of the steel beam 100 are connecting parts, which are formed through optimized design. The connecting parts are used for special connection with the corbel to meet the requirements of use.

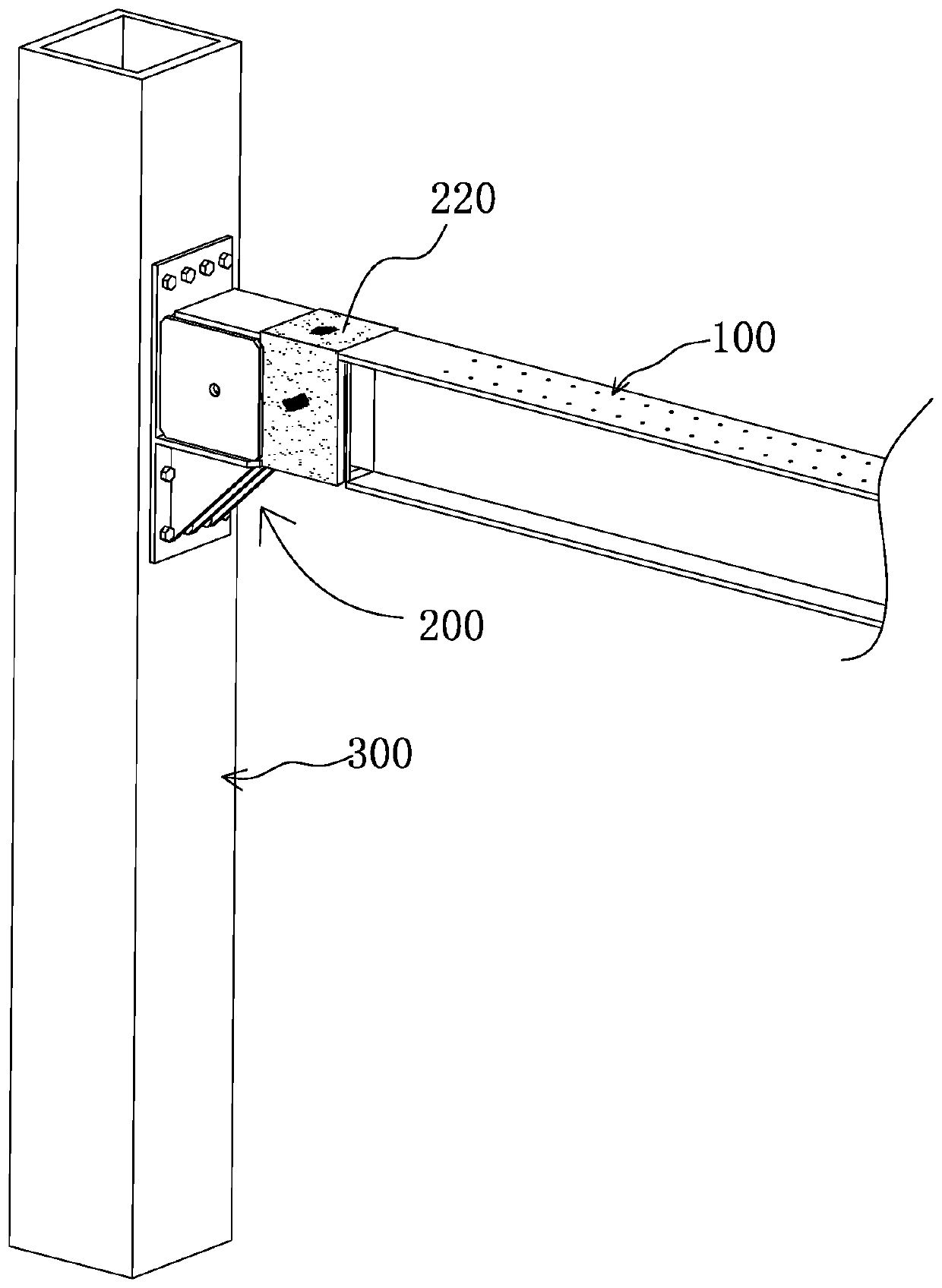

[0052]The corbel 200 is installed on the column 300 by welding or fixing. The corbel 200 is composed of a support part 210 and a moun...

Embodiment 2

[0069] As a way to improve, the separator can also adopt a structure with folds 1114, the structure of the separator can refer to Figure 11 , forming a connection with a certain degree of elasticity, this structure is more portable and more shock-resistant. This structure is suitable for the connection of steel beams and steel columns of light steel structures. At the same time, the structure of the folds can store more emulsified asphalt in the gaps of the folds to form a high-strength bond.

Embodiment 3

[0071] Referring to the figure, this embodiment can also achieve a more excellent installation effect. In this embodiment, after installation, a more excellent floor installation space can be formed. Specifically, the installation parts at both ends of the steel beam are designed to fold down The curved bending structure, and a plug-in structure is provided at the position of the bending structure. In this way, sufficient installation space is formed at the connecting parts at both ends of the steel beam, making the connecting parts easier to install.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com