Staged online monitoring method for steelmaking by refining furnace

A refining furnace, stage-by-stage technology, applied in stage-by-stage online monitoring, in the field of metal materials, to achieve the effects of improving efficiency, shortening refining time, and reducing the incidence of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

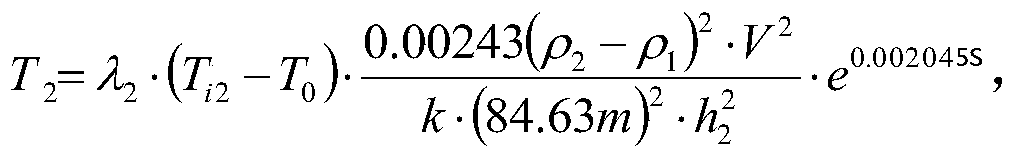

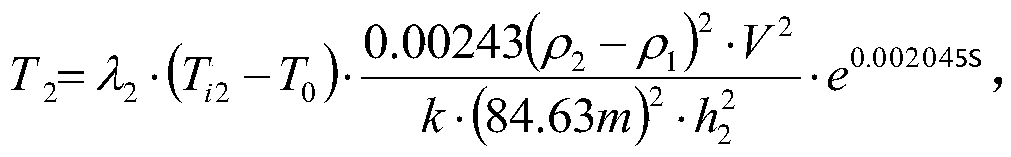

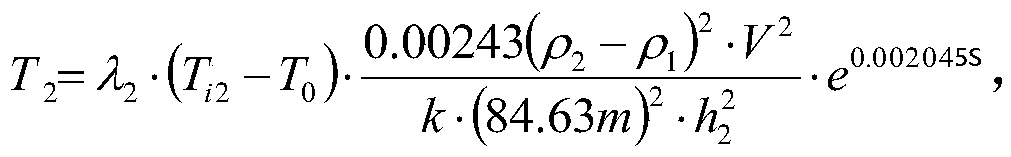

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the description.

[0033] The invention provides a stage-by-stage online monitoring method for steelmaking in a refining furnace. By monitoring the steelmaking process at each stage in the refining furnace and adjusting according to the monitoring signals at each stage, the smooth progress of the refining process is ensured, specifically including as follows:

[0034] Monitoring the argon blowing signal, the first heating stage signal and the second heating stage signal in the argon blowing stage in the refining furnace to obtain multiple monitoring signals;

[0035] Comparing the monitoring signal with the normal working signal and then classifying it to obtain an identifier representing the operating status of the refining furnace; according to the operating status identifier of the refining furnace, determine the operating status of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com