Nano modified cement-based underwater non-dispersible material and preparation method thereof

A nano-modification and cement technology, which is used in construction, seawall revetment, water conservancy projects, and bridges. It can solve problems such as poor fluidity and dispersion resistance, low strength, and turbid water quality, and achieve good construction performance and durability. Dispersion resistance, effect of dispersion resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

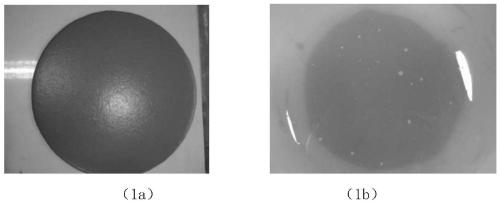

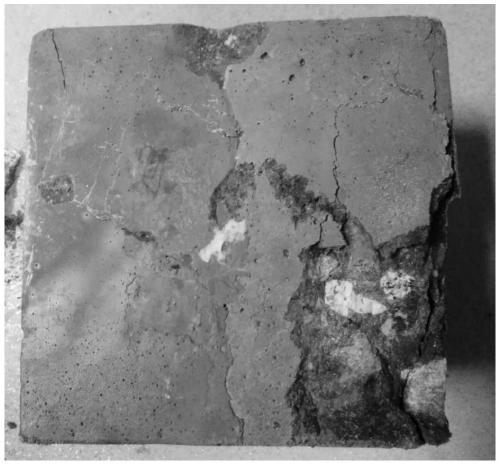

[0038] 525 cement: 50%, silica fume: 7%, fly ash: 10%, limestone powder: 9%, mineral powder: 10%, metakaolin: 5%, superfine cement: 9%, composed of cementitious materials, glue The gelling material is 1000g, then add aluminum sulfate: 10%, sodium metasilicate: 15%, non-dispersing agent: 0.52%, water reducing agent: 16%, defoaming agent: 0.1%, accounting for the mass fraction of gelling material, The water reducer is a powder type polycarboxylate water reducer, P803 type defoamer, and the non-dispersant is polyacrylamide flocculant, and then add 6#, 7#, 8# with a mass ratio of 5:3:2 Quartz sand, the mass ratio of the total amount of quartz sand to the cementitious material is 1:1, and the amount of water added is 540g. refer to figure 1 , 2 Tested with 3, the fluidity of the freshly mixed non-dispersible material is 260mm (in air), the content of suspended matter is 85mg / L, the 1d flexural strength is 2.1MPa, the compressive strength is 7.1MPa, the 3d flexural strength is 5.5...

Embodiment 2

[0040] 525 cement: 50%, silica fume: 7%, fly ash: 10%, limestone powder: 9%, mineral powder: 10%, metakaolin: 5%, superfine cement: 9%, composed of cementitious materials, glue The gelling material is 1000g, and then add aluminum sulfate: 10%, sodium metasilicate: 15%, nano-silicon dioxide: 10%, non-dispersing agent: 0.52%, water reducing agent 16%, disinfectant Foaming agent: 0.1%. Among them, the water reducing agent is a powder type polycarboxylate water reducing agent, P803 type defoamer, and the non-dispersing agent is polyacrylamide flocculant, and then add a mass ratio of 5:3:2 6#, 7#, 8# quartz sand, the mass ratio of the total amount of quartz sand to the cementitious material is 1:1, and the amount of water added is 540g. refer to figure 1 , 2Tested with 3, the fluidity of the freshly mixed non-dispersible material is 255mm (in air), the content of suspended matter is 79mg / L, the 1d flexural strength is 3.3MPa, the compressive strength is 9.8MPa, the 3d flexural st...

Embodiment 3

[0042] 525 cement: 55%, silica fume: 7%, fly ash: 5%, mineral powder: 6%, metakaolin: 5%, superfine cement: 17%, limestone powder: 5%, composed of cementitious materials, glue The gelling material is 1000g, and then add aluminum sulfate: 10%, sodium metasilicate: 14%, nano-silicon dioxide: 10%, non-dispersing agent: 0.5%, water reducing agent 12%, disinfectant Foaming agent: 0.1%. Among them, the water reducing agent is a powder type polycarboxylate water reducing agent, P803 type defoamer, and the non-dispersing agent is polyacrylamide flocculant, and then add a mass ratio of 5:3:2 6#, 7#, 8# quartz sand, the mass ratio of the total amount of quartz sand to the cementitious material is 1:1, and the amount of water added is 491g. refer to figure 1 , 2 Tested with 3, the fluidity of the freshly mixed non-dispersible material is 240mm (in air), the content of suspended matter is 56mg / L, the 1d flexural strength is 3.6MPa, the compressive strength is 15.2MPa, the 3d flexural st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com