Silicon hydroxyl magnetic bead and preparation method and application thereof

A technology of silanol and magnetic beads, which is applied in the field of silanol magnetic beads and its preparation, can solve the problems of inconsistent magnetic content of magnetic bead particles, easy generation of defects in nanoparticles, cumbersome sample screening process, etc., and achieve good packaging compactness and easy Post-processing, avoiding the effect of post-screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Fe 3 o 4 Synthesis of Nanoparticles

[0050] (1) 8.1g (0.03mol) of FeCl 3 ·6H 2 O. 120mL (2.15mol) of ethylene glycol (EG), 4.86g (0.0165mol) of trisodium citrate, and 10.0g (0.12mol) of sodium acetate (NaAc) were mixed and stirred, and ultrasonically treated at 30w for 15min to form a uniform Emulsion, then pass the emulsion through a 400-mesh standard sieve to remove the large particles that have not formed the emulsion;

[0051] (2) Transfer the above-mentioned standard emulsion to a polytetrafluoroethylene liner digestion tank, put it into a reaction kettle, and take it out after being incubated at 220°C for 18h;

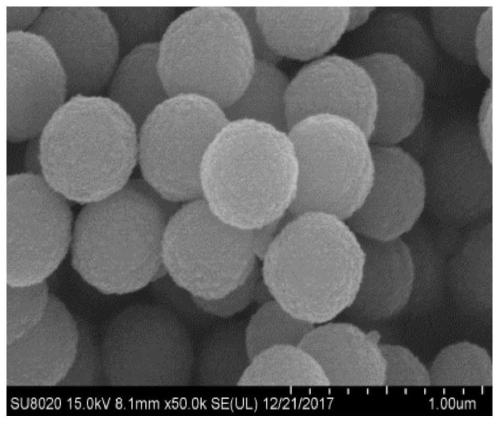

[0052] (3) After the high-pressure digestion tank is cooled, use a magnet to separate the black precipitate, wash it 3 times with pure water and absolute ethanol, clean it by magnetic suction, and dry it. 3 o 4 The particle size is about 380nm.

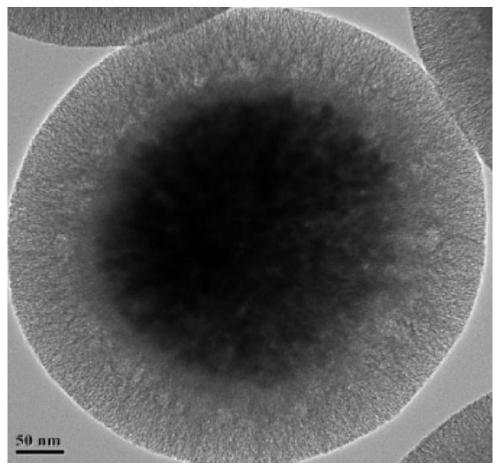

[0053] 2. ALD deposition of SiO 2 membrane

[0054] (1) the above-prepared Fe 3 o 4 Take 1.0g of...

Embodiment 2

[0059] 1. Fe 3 o 4 Synthesis of Nanoparticles

[0060] (1) 4.0g (0.015mol) FeCl 3 ·6H 2 O, 100mL (1.8mol) ethylene glycol 1.86mol (EG), 3.12g (0.0106mol) trisodium citrate, 4.86g (0.059mol) sodium acetate (NaAc) mixed and stirred, 30w ultrasonic treatment for 15min to form a uniform Emulsion, then pass the emulsion through a 400-mesh standard sieve to remove the large particles that have not formed the emulsion;

[0061] (2) Transfer the above-mentioned standard emulsion to a polytetrafluoroethylene liner digestion tank, put it into a reaction kettle, and take it out after being incubated at 160° C. for 8 hours;

[0062] (3) After the high-pressure digestion tank is cooled, use a magnet to separate the black precipitate, wash it 3 times with pure water and absolute ethanol, clean it by magnetic suction, and dry it. 3 o 4 Particle size 150nm.

[0063] 2. ALD deposition of SiO 2 membrane

[0064] (1) the above-prepared Fe 3 o 4 Take 1.0g of the powder and place it in ...

Embodiment 3

[0069] 1. Fe 3 o 4 Synthesis of Nanoparticles

[0070] (1) 6.0g (0.022mol) FeCl 3 ·6H 2 0, 120mL (2.15mol) ethylene glycol (EG), 4.86g (0.0165mol) trisodium citrate, 7.92g (0.096mol) sodium acetate (NaAc) mixed and stirred, 30w ultrasonic treatment 15min, make it form uniform emulsion, Afterwards, pass the emulsion through a 400-mesh standard sieve to remove large particles that have not formed the emulsion;

[0071] (2) Transfer the above-mentioned standard emulsion to a polytetrafluoroethylene liner digestion tank, put it into a reaction kettle, and take it out after being incubated at 200°C for 10h;

[0072] (3) After the high-pressure digestion tank is cooled, use a magnet to separate the black precipitate, wash it 3 times with pure water and absolute ethanol, clean it by magnetic suction, and dry it. 3 o 4 Particle size 540nm.

[0073] 2. ALD deposition of SiO 2 membrane

[0074] (1) the above-prepared Fe 3 o 4 Take 1.0g of the powder and place it in the ALD eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com