Pipeline inner wall cleaning machine

A technology for cleaning machines and pipes, which is applied in the field of cleaning devices and pipe inner wall cleaning machines, and can solve problems such as large residue, low efficiency, and large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

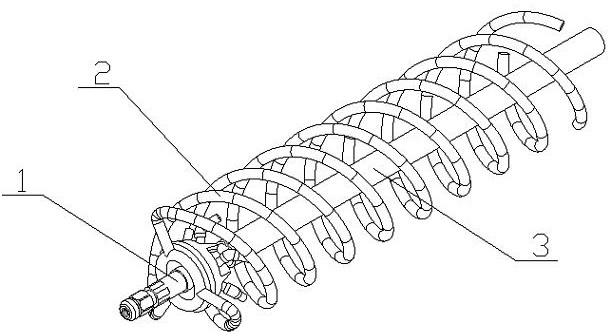

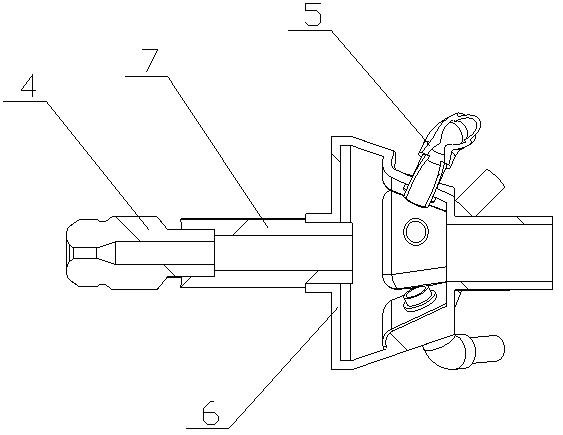

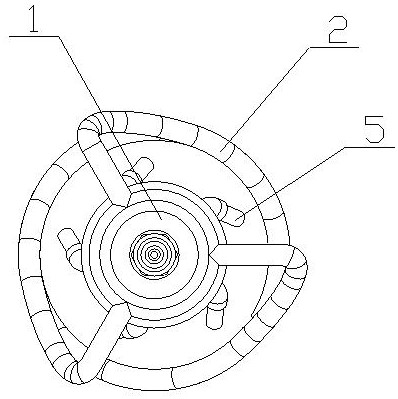

[0026] The pipeline inner wall cleaning machine of the present invention is composed of a cleaning head (1), a slag discharge structure (2) and a water delivery pipe (3). connected, the drainage structure is placed on the cleaning head (1), the slag discharge structure (2) extends to the side of the water delivery pipe (3), the water delivery pipe (3) is a hose, and the cleaning head (1) It consists of a broken wall nozzle (4), a side flushing nozzle (5), a nozzle assembly (6) and an extension tube (7). The nozzle assembly (6) is a hollow circular platform structure, and the two ends of the circular platform are provided with connecting threads One end of the extension tube (7) is screwed and placed in the threaded sleeve at the large end of the round table, and the wall-breaking nozzle (4) is placed at the other end of the extension tube (7). The internal channel of the wall-breaking nozzle (4) is a variable-diameter structure. The side of the nozzle assembly (6) is provided ...

Embodiment 2

[0035] The difference between Embodiment 2 and Embodiment 1 is that the nozzle on the side flushing nozzle (5) is a special-shaped nozzle (13). The cutting ability of the jet stream can clean and wash the scale (12) in a large area, and improve the cleaning efficiency of the scale (12), which is better than the columnar jet flushing effect;

Embodiment 3

[0037]The difference between embodiment 3 and embodiment 1 is that there are two groups of lateral flushing nozzles (5), and the distribution directions of the two groups of lateral nozzles are opposite to each other, so that the scale (12) can be supplemented from the outside when extending in. The scouring increases the scouring area of the outer surface, and the stubborn scale (12) is cleaned and washed multiple times through the reciprocating movement to increase the cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com