Method for controlling organic arsenic pollution in water by ordered mesoporous layered bimetal hydroxide

A hydroxide and bimetal technology, applied in the direction of alkali metal oxide/hydroxide, metal/metal oxide/metal hydroxide catalyst, alkali metal compound, etc., can solve the problem of arsenic pollutant removal, etc. Achieve the effects of small secondary pollution, easy realization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

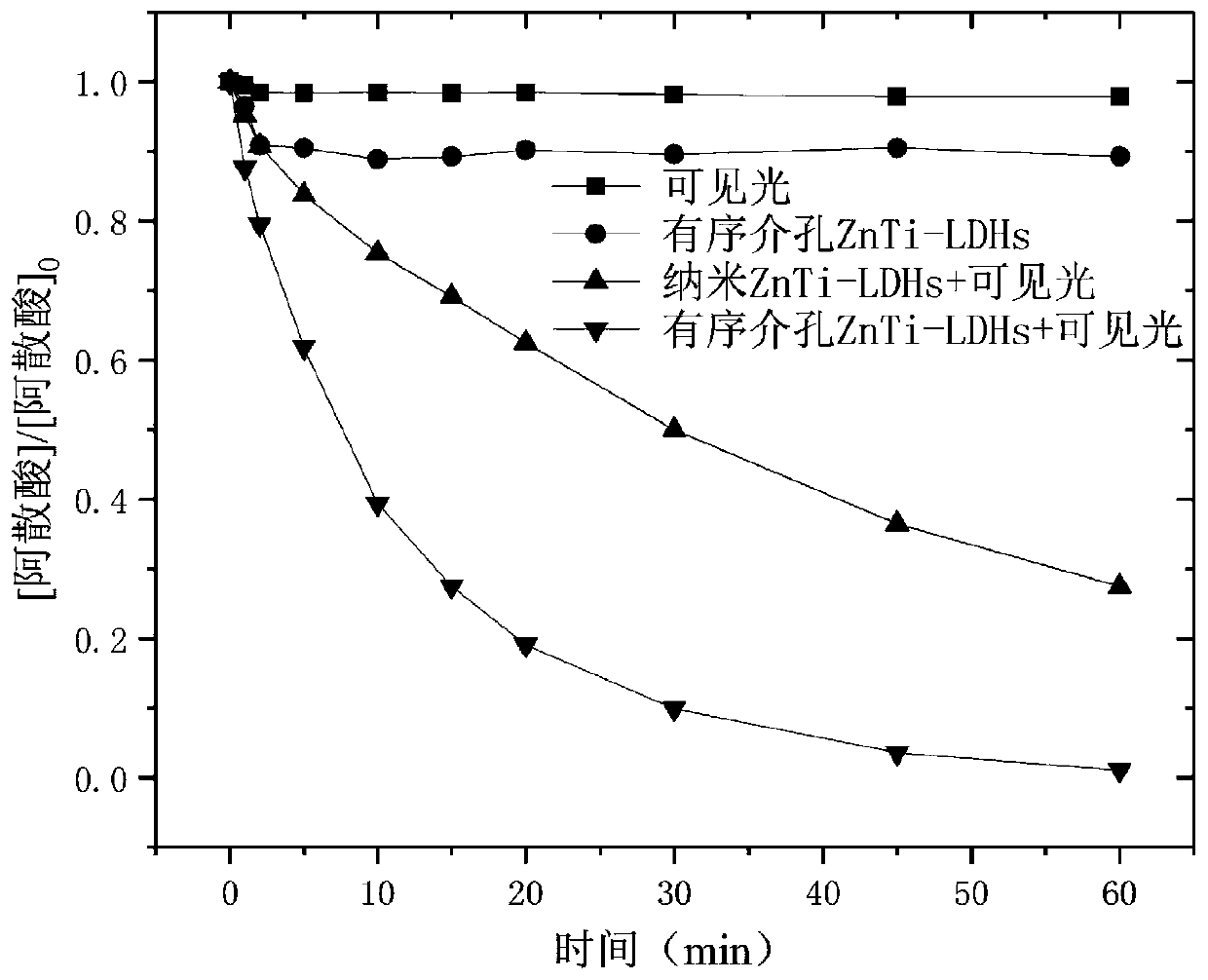

Image

Examples

Embodiment 1

[0034] A method for controlling organic arsine pollution in water by using ordered mesoporous layered double hydroxides, said method comprising the steps of:

[0035] Step 1: Preparation of ordered mesoporous ZnTi-LDHs

[0036] S1. Add 5.04g of poloxamer into 100mL of deionized water, and stir vigorously at 60°C until completely dissolved;

[0037] S2, successively add 0.22mLTiCl 4 , 1.19gZn (NO 3 ) 2 ·6H 2 0 and 3g of urea are added to the mixed solution of step S1 and vigorously stirred until completely dissolved;

[0038]S3. Put the mixed solution in step S2 in an autoclave for aging for 48 hours at a temperature of 130° C., centrifuge the aged solution to obtain a precipitate, wash the precipitate with ethanol and deionized water several times in turn, and then place the precipitate at 60° C. Dry overnight at temperature;

[0039] S4. Grinding the dried solid first, then placing it in a muffle furnace at a temperature of 350° C. for 3 hours, and naturally cooling to ...

Embodiment 2

[0047] A method for controlling organic arsine pollution in water by using ordered mesoporous layered double hydroxides, said method comprising the steps of:

[0048] Step 1: Preparation of ordered mesoporous ZnTi-LDHs

[0049] S1. Add 5.04g of poloxamer into 100mL of deionized water, and stir vigorously at 60°C until completely dissolved;

[0050] S2, successively add 0.22mLTiCl 4 , 1.19gZn (NO 3 ) 2 ·6H 2 0 and 3g of urea are added to the mixed solution of step S1 and vigorously stirred until completely dissolved;

[0051] S3. Put the mixed solution in step S2 in a high-pressure reactor for aging at 120°C for 40 hours, centrifuge the aged solution to obtain a precipitate, wash the precipitate with ethanol and deionized water several times in turn, and then place the precipitate at 50°C Dry overnight at temperature;

[0052] S4. Grinding the dried solid first, then placing it in a muffle furnace for 3.5 hours at a temperature of 300° C., and cooling to room temperature ...

Embodiment 3

[0060] The ratio of the dosage mg of ordered mesoporous ZnTi-LDHs in this embodiment to the volume L of raw water is 400-500:1, and other steps are the same as in Embodiment 1.

[0061] The removal rate of arsanic acid in this embodiment is 99.3%. Inorganic arsenic was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com